High-gradient intense magnetic field horizontal composite magnetic gathering roller

A technology of strong magnetic field and magnetic gathering roller, which is applied in the direction of high-gradient magnetic separator, etc., can solve the problems of affecting the output of magnetic separation, easily injured hands, and difficult to level the surface, so as to enhance the ability of impurity removal, purification and separation, and increase safety performance and reliability, and the effect of improving the concentrate grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

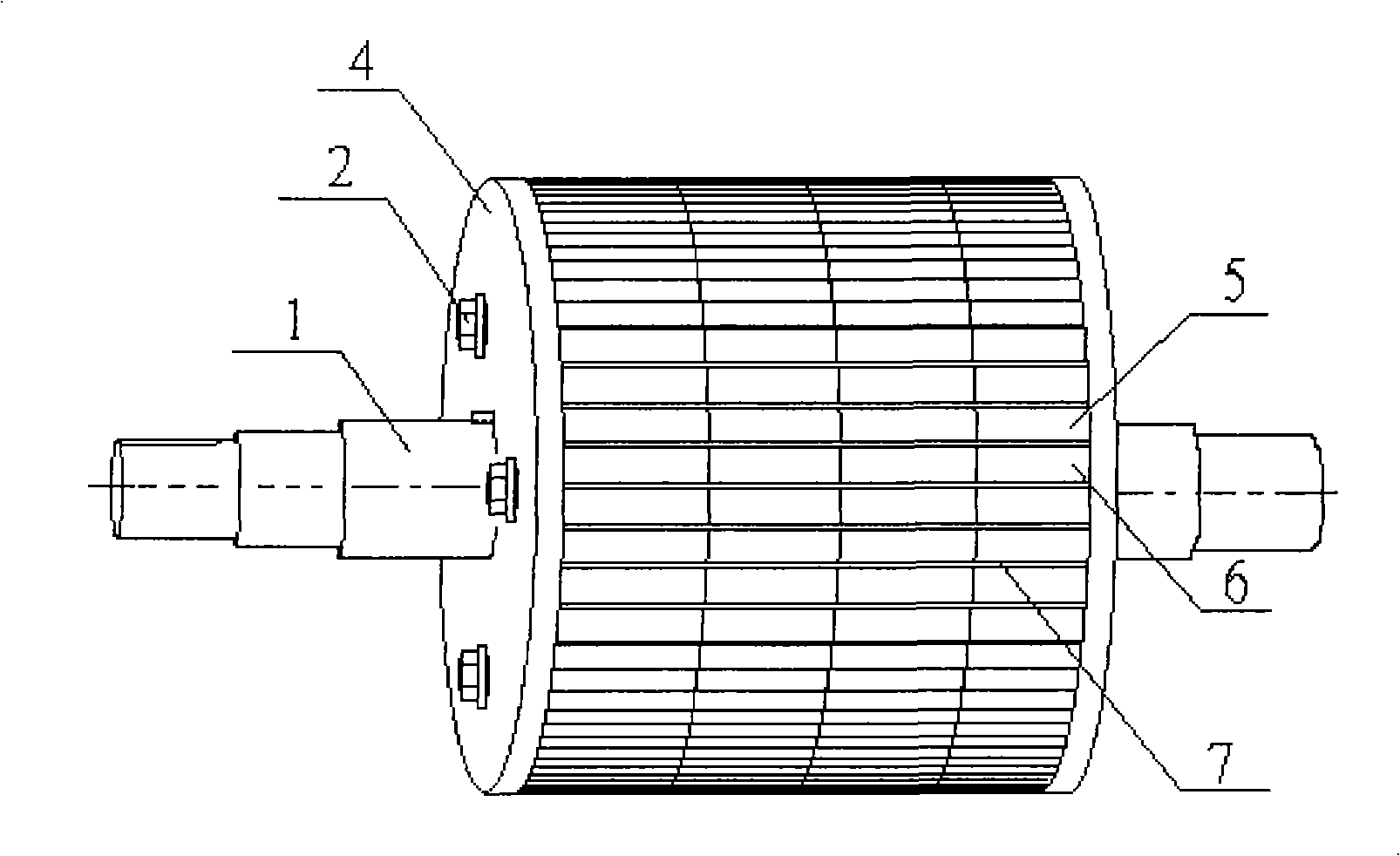

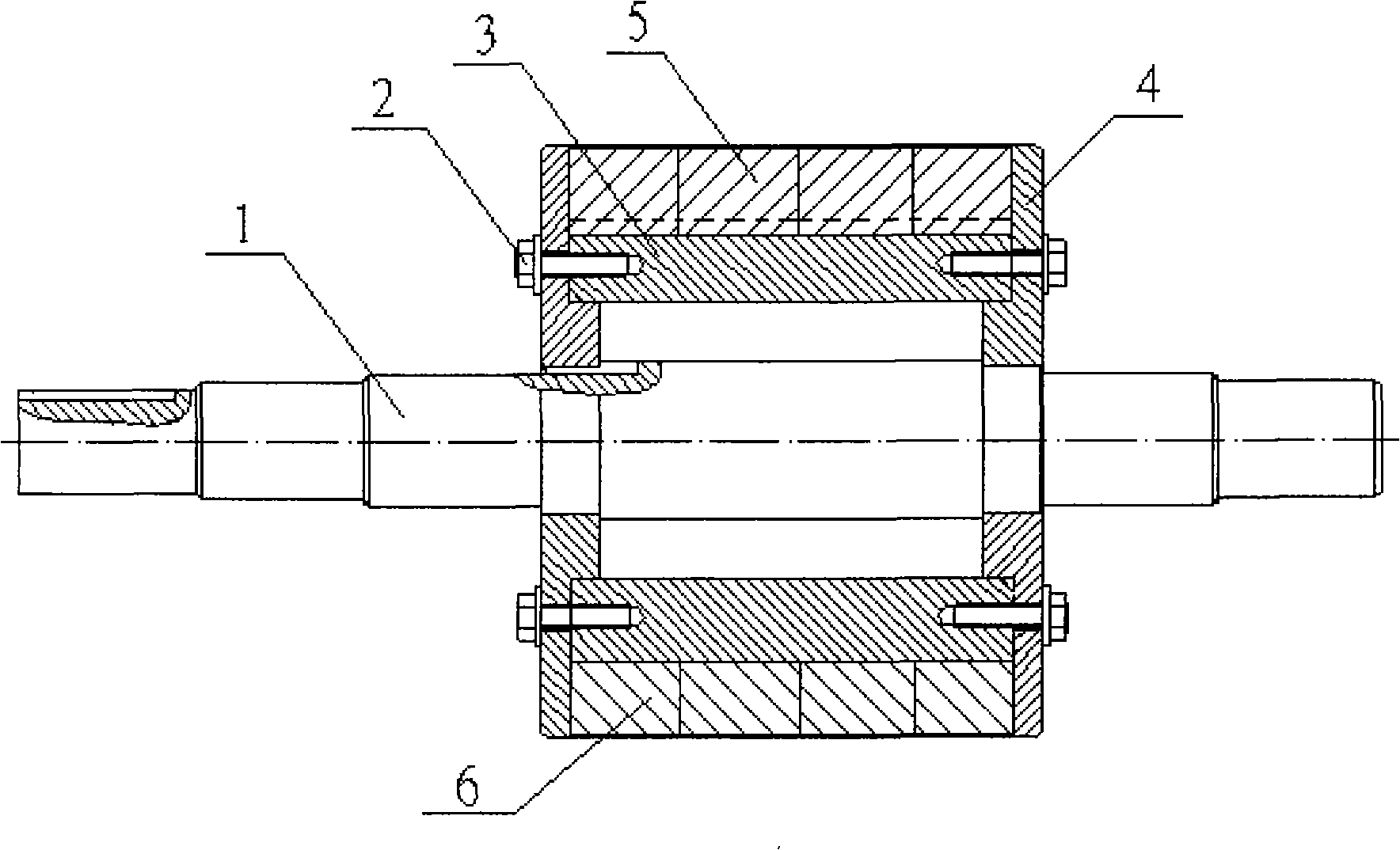

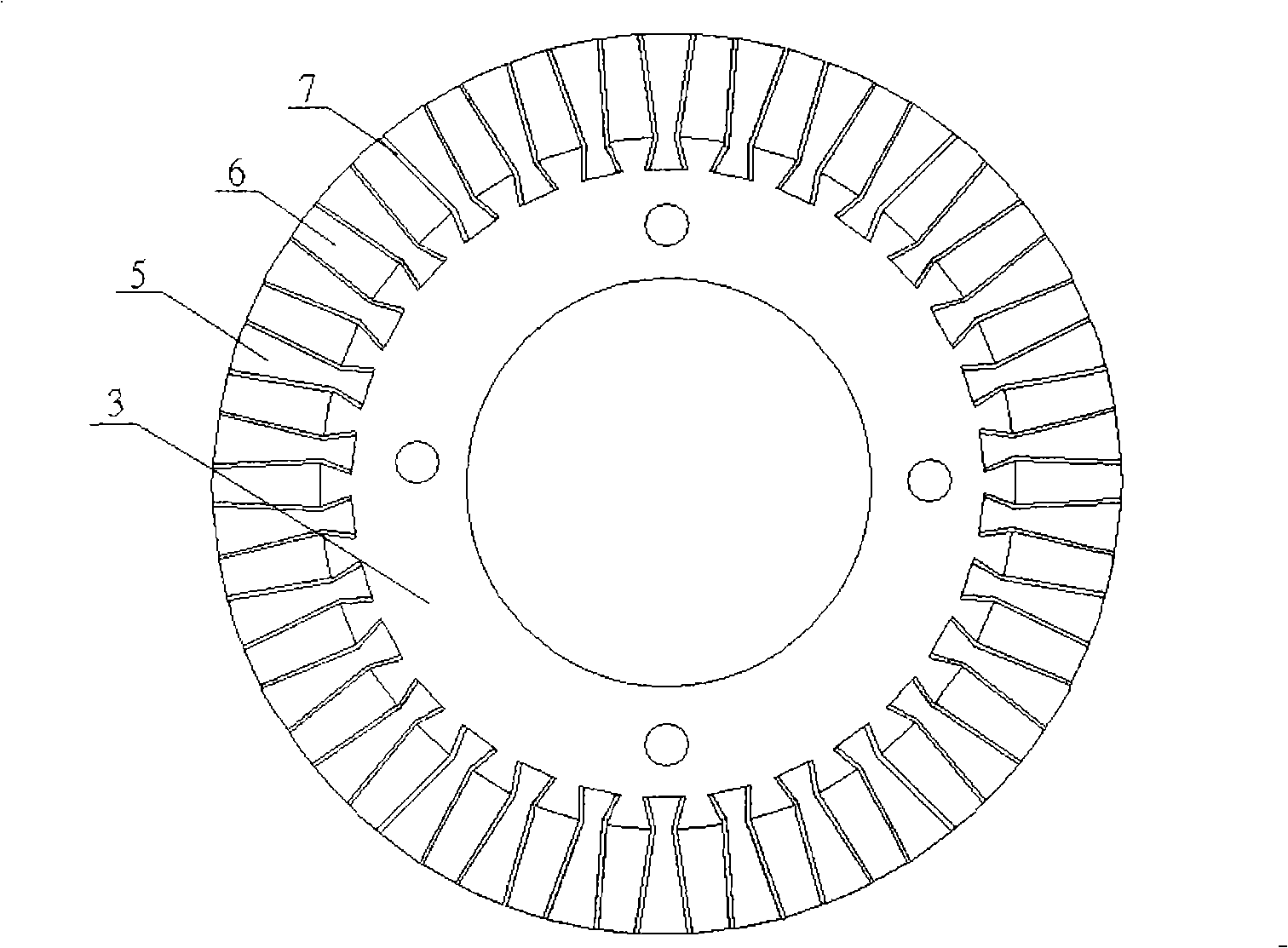

[0029] like Figure 1~4As shown, the high-gradient strong magnetic field horizontal composite magnetic gathering roller of the present invention has a magnetic roller mandrel 1, and the outer coaxial center of the magnetic roller mandrel 1 is equipped with a yoke roller whose inner diameter is greater than the outer diameter of the magnetic roller mandrel 1 In the cylinder 3, the outer cylinder wall of the yoke roller 3 is evenly provided with a circle of primary dovetail grooves 3a arranged in parallel in the axial direction along the circumferential direction for fixing the double dovetail-shaped permanent magnetic strips 5 . The double dovetail-shaped permanent magnet strip 5 is composed of an upper dovetail-shaped part 5b and a lower dovetail-shaped part 5a that are arranged oppositely and connected as a whole in two dovetail-shaped cross-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com