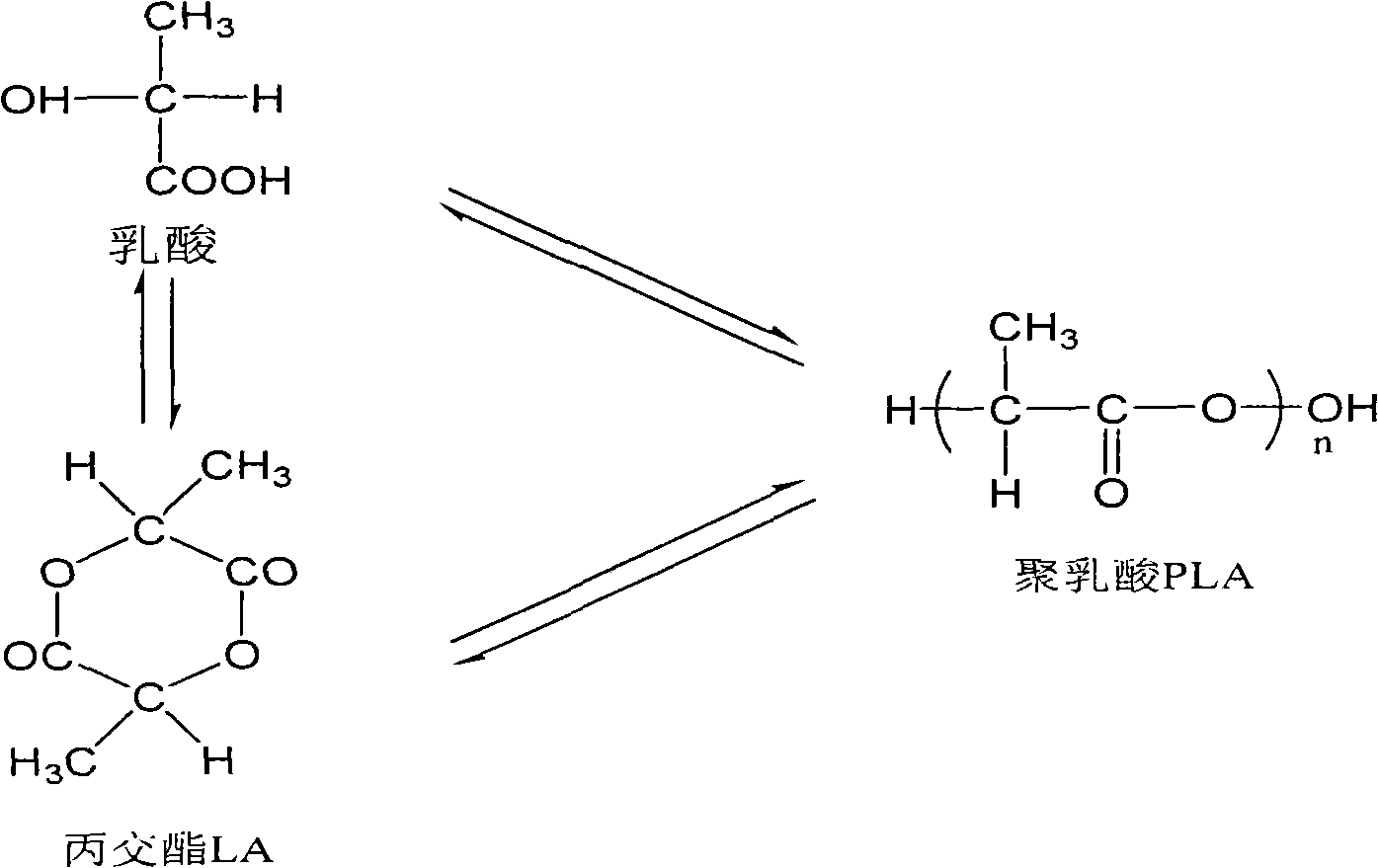

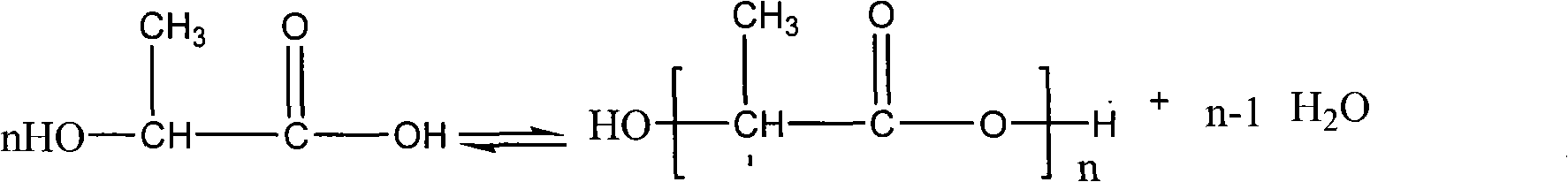

Method for preparing polylactic acid with sulfamic acid compound as catalyst

A technology of sulfamic acid and compounds, which is applied in the field of direct polycondensation of lactic acid under the action of a composite catalyst to prepare high-molecular-weight polylactic acid, can solve the problems of poor thermal stability of polymers, large dosage, and low melting point of polylactic acid, etc., and achieve simple process , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

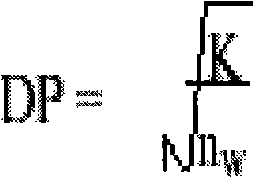

[0056] After injecting 500g of L-lactic acid solution (90wt%) into a 1000ml three-necked bottle, the three-necked bottle was put into an oil bath. After installing mechanical stirring, connecting the vacuum / nitrogen system, and inserting the thermocouple thermometer, replace nitrogen twice under stirring conditions. At normal pressure, the temperature was raised to 130°C in 20 minutes. Under the premise of not bumping, the pressure is gradually reduced to 50kPa, 20kPa, 10kPa, 5kPa in stages and kept at each pressure stage for 30 minutes (including decompression time), that is, a total of 2 hours of dehydration under reduced pressure to obtain 430g Lactic acid polymer A1, the degree of polymerization is 3 (determined by end group analysis, the same below)

Embodiment A2

[0058] After injecting 500g of L-lactic acid solution (90wt%) into a 1000ml three-necked bottle, the three-necked bottle was put into an oil bath. After installing mechanical stirring, connecting the vacuum / nitrogen system, and inserting the thermocouple thermometer, replace nitrogen twice under stirring conditions. At normal pressure, the temperature was raised to 100°C in 15 minutes. Under the premise of not bumping, the pressure is gradually reduced to 40kPa, 20kPa, 10kPa, 5kPa in stages and kept at each pressure stage for 120 minutes (including decompression time), that is, a total of 8 hours of dehydration under reduced pressure to obtain 410g Lactic acid polymer A2, the degree of polymerization is 4.

Embodiment A3

[0060] After injecting 500g of L-lactic acid solution (90wt%) into a 1000ml three-necked bottle, the three-necked bottle was put into an oil bath. After installing mechanical stirring, connecting the vacuum / nitrogen system, and inserting the thermocouple thermometer, replace nitrogen twice under stirring conditions. Under normal pressure, the temperature was raised to 80°C in 10 minutes. On the premise of not bumping, adjust the pressure and temperature to 50kPa and 80°C, 40kPa and 100°C, 30kPa and 120°C, 20kPa and 140°C, 10kPa and 160°C, 5kPa and 180°C in stages Hold for 30 minutes (including temperature and pressure adjustment time), that is, dehydration under reduced pressure for a total of 2.5 hours, to obtain 418 g of lactic acid polymer A3 with a degree of polymerization of 5.

[0061] Preparation of lactic acid prepolymer

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com