Preparation of mixed enzyme of molecular sieve immobilized barley beta-amylase and Pullulanase

A technology of pullulanase and molecular sieve, which is applied in the field of preparation of two mixed enzymes of barley β-amylase and pullulanase immobilized by molecular sieve, which can solve the problems of low yield, unsuitability for continuous production, short lifespan, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

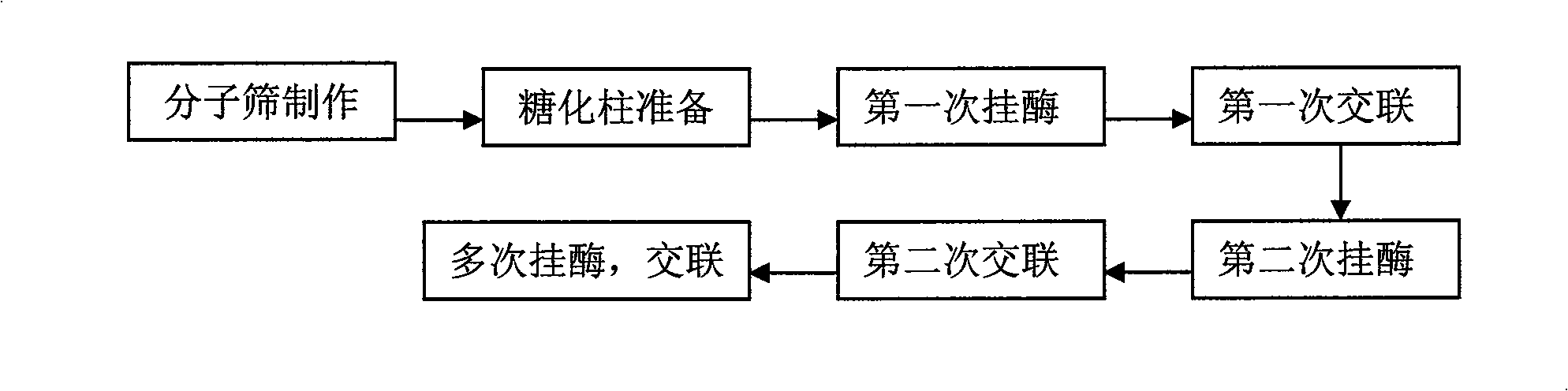

[0015] Embodiment: The present invention uses shaped molecular sieves to immobilize barley β-amylase and pullulanase two mixed enzyme preparation methods, specifically comprising the following steps:

[0016] (1) Production of molecular sieves:

[0017] Molecular sieves use β-zeolite as raw material and add about 20% Al 2 o 3 The binder is mixed and pressed, dried at room temperature, roasted, crushed into granules, sieved with 20-40 mesh, and the granules are uniform in size.

[0018] (2) Preparation of saccharification column

[0019] Put some broken porcelain in the glass column, put some glass filaments on it, then put the formed molecular sieve into the column, and add an insulating layer outside the glass column.

[0020] (3) The first time to hang the enzyme

[0021] Take barley β-amylase and pullulanase (Novozymes) two enzymes, mix them evenly at a mass ratio of 1:2, take a quantitative mixed enzyme, and circulate it with a metering pump for 5-10 hours at 25-30°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com