Seal connecting method of porous ceramic plate column

A technology of porous ceramic plate and connection method, which is applied in heating methods, household heating, space heating and ventilation details, etc., can solve the problems of increased cost, complicated installation, low molding efficiency, etc., to speed up construction progress and improve reliability. performance, reducing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

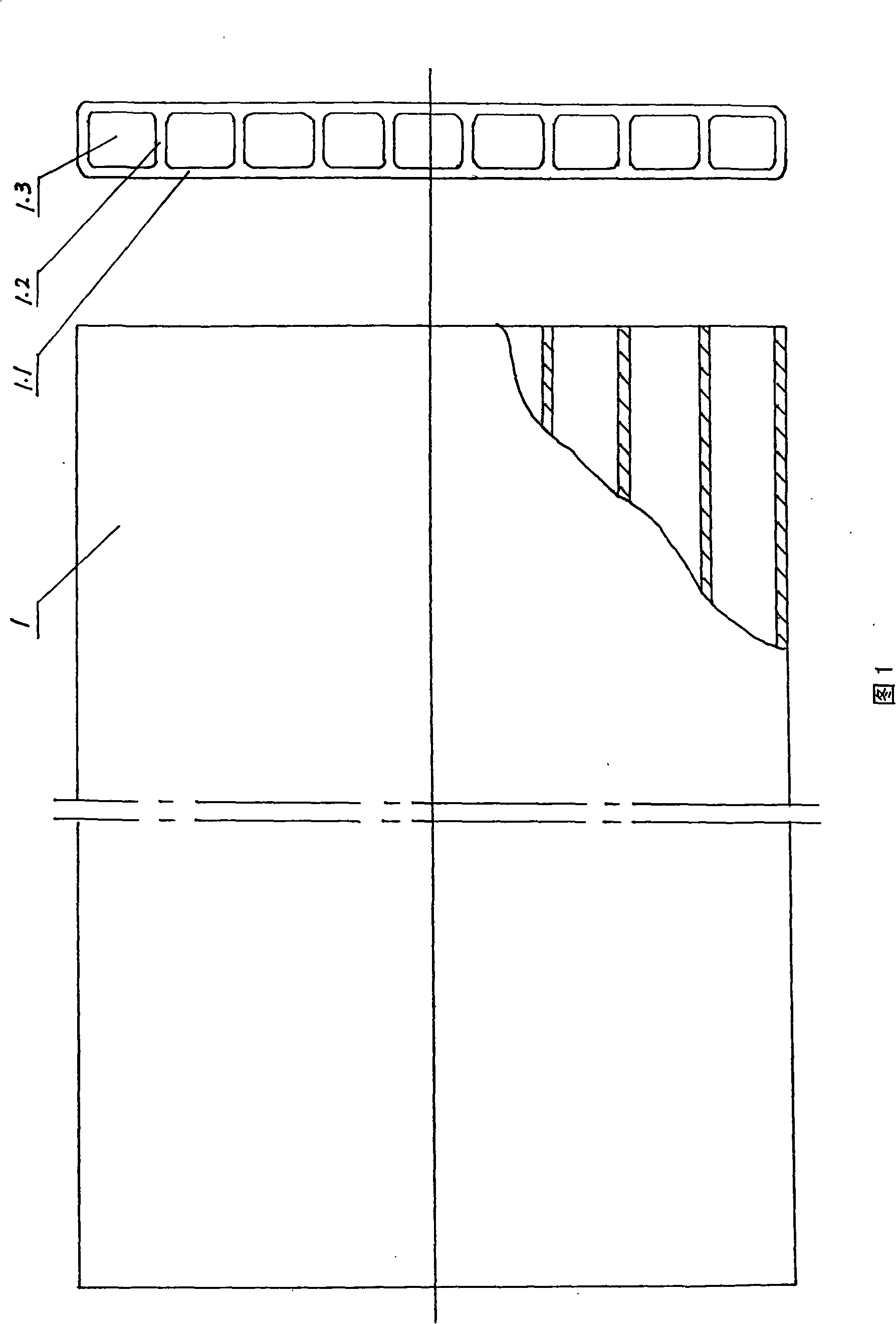

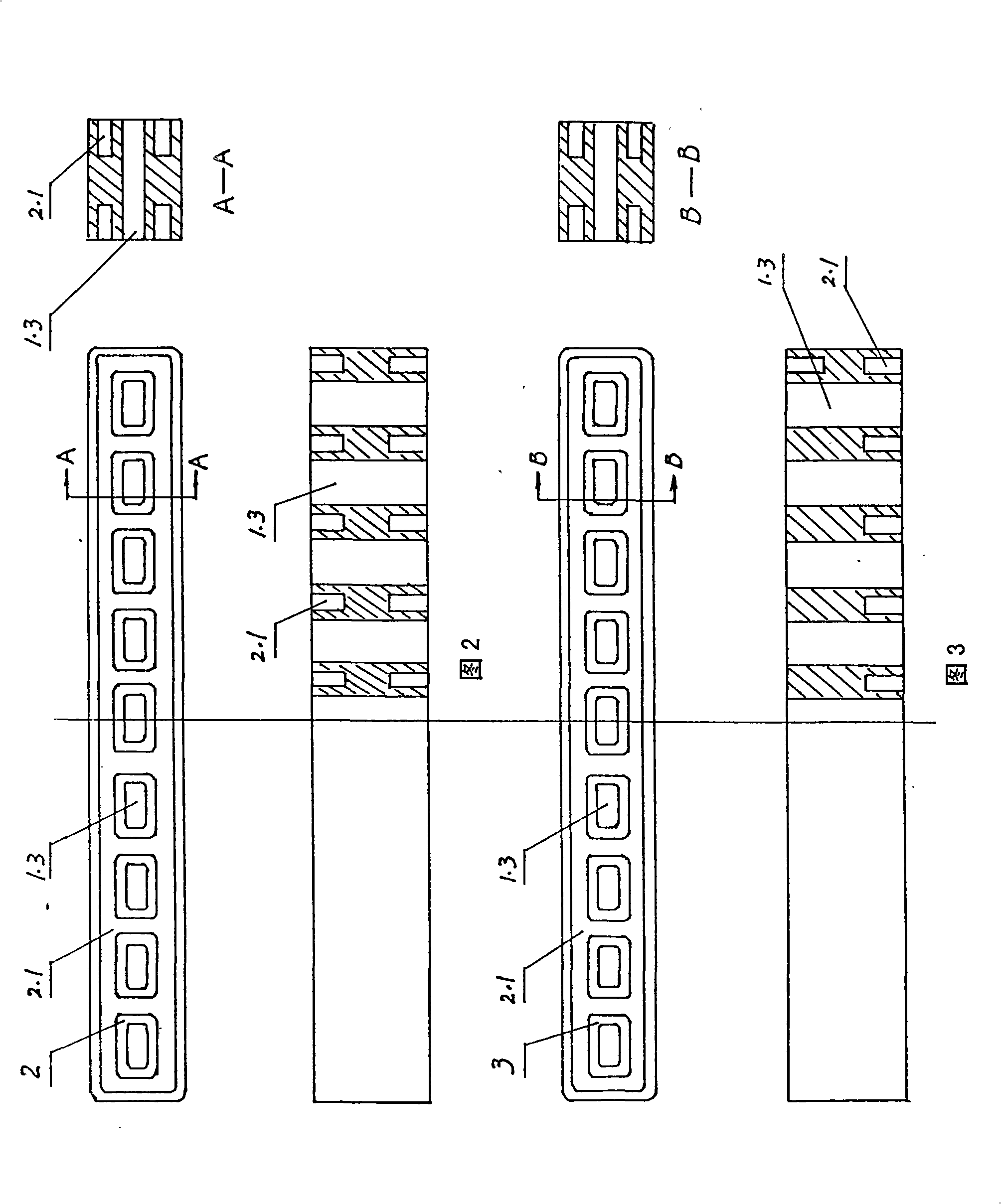

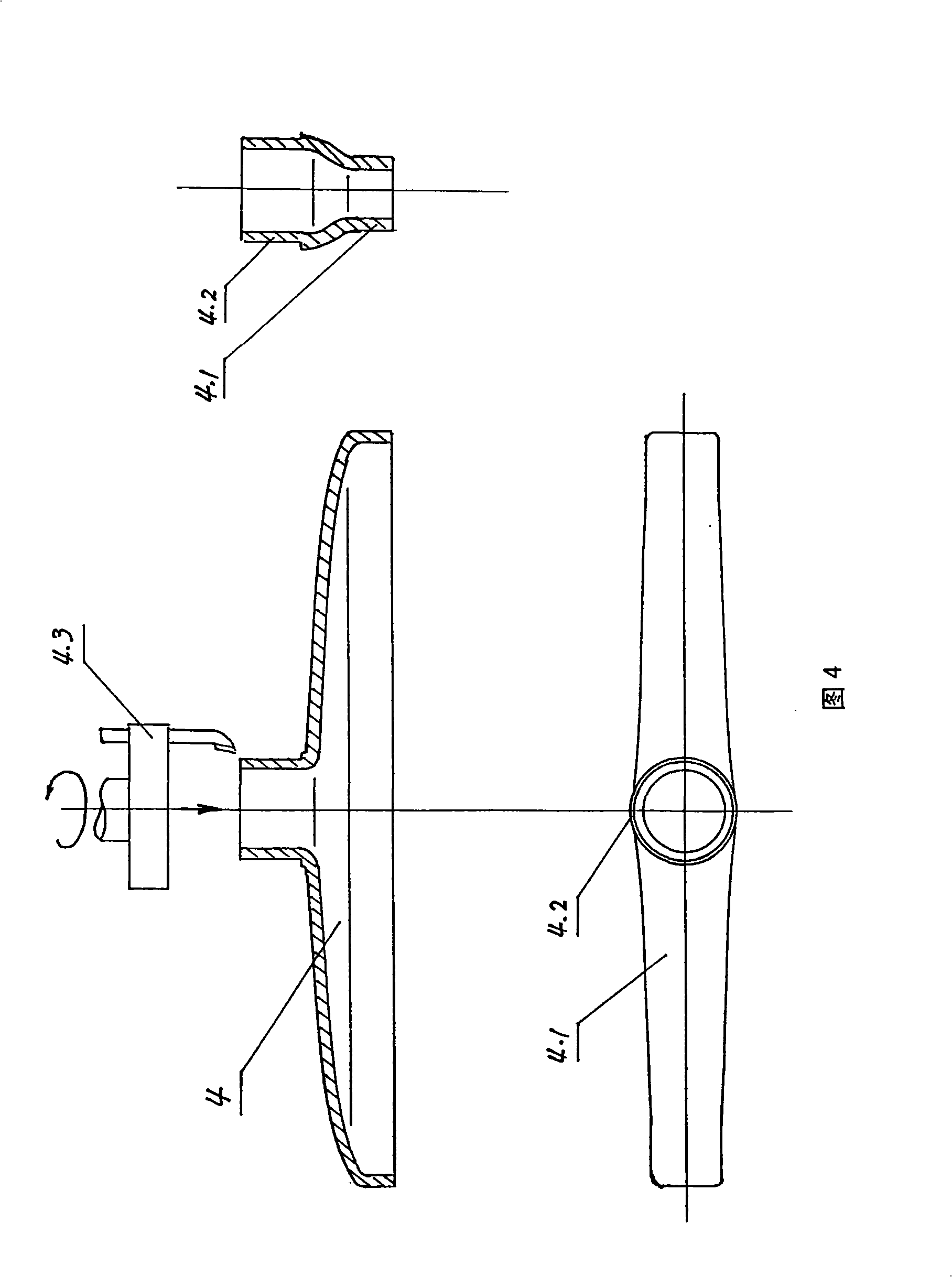

[0058] 1. The length of the porous ceramic plate is 1500mm, the width is 610mm, the total thickness is 26mm, the outer wall thickness is 2.6mm, and the partition wall thickness is 4.3mm. The centerline of the outer wall and the centerline of the partition wall in the cross-section of the plate coincide, the groove width is 6-8mm, the annular groove width of the ∪-type transitional socket interface is 8mm, the annular outer wall thickness of the converging port is 5mm, the outer diameter of the circular pipe is 53mm, the inner diameter is 40mm, and the silicon Rubber is used as a sealing and connecting agent, and the above-mentioned porous ceramic plates, ∪-shaped socket interface, ∪-shaped transitional socket interface, and collection ports are combined into a column of porous ceramic plates.

[0059] 2. The tandem of porous ceramic plates as described in Example 1, the width of the porous ceramic plates is 800 mm, and high polymer cement is used as the sealing agent.

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com