Photoetching objective lens

A lithography objective lens and lens technology, applied in the field of lithography objective lens, can solve the problem that the positioning accuracy and resolution of the fine pattern printed board are reduced, the liquid photoresist is stained on the master plate, and the resolution cannot be very good. High problems, to achieve the effect of large one-time exposure area, convenient and practical one-time exposure area, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

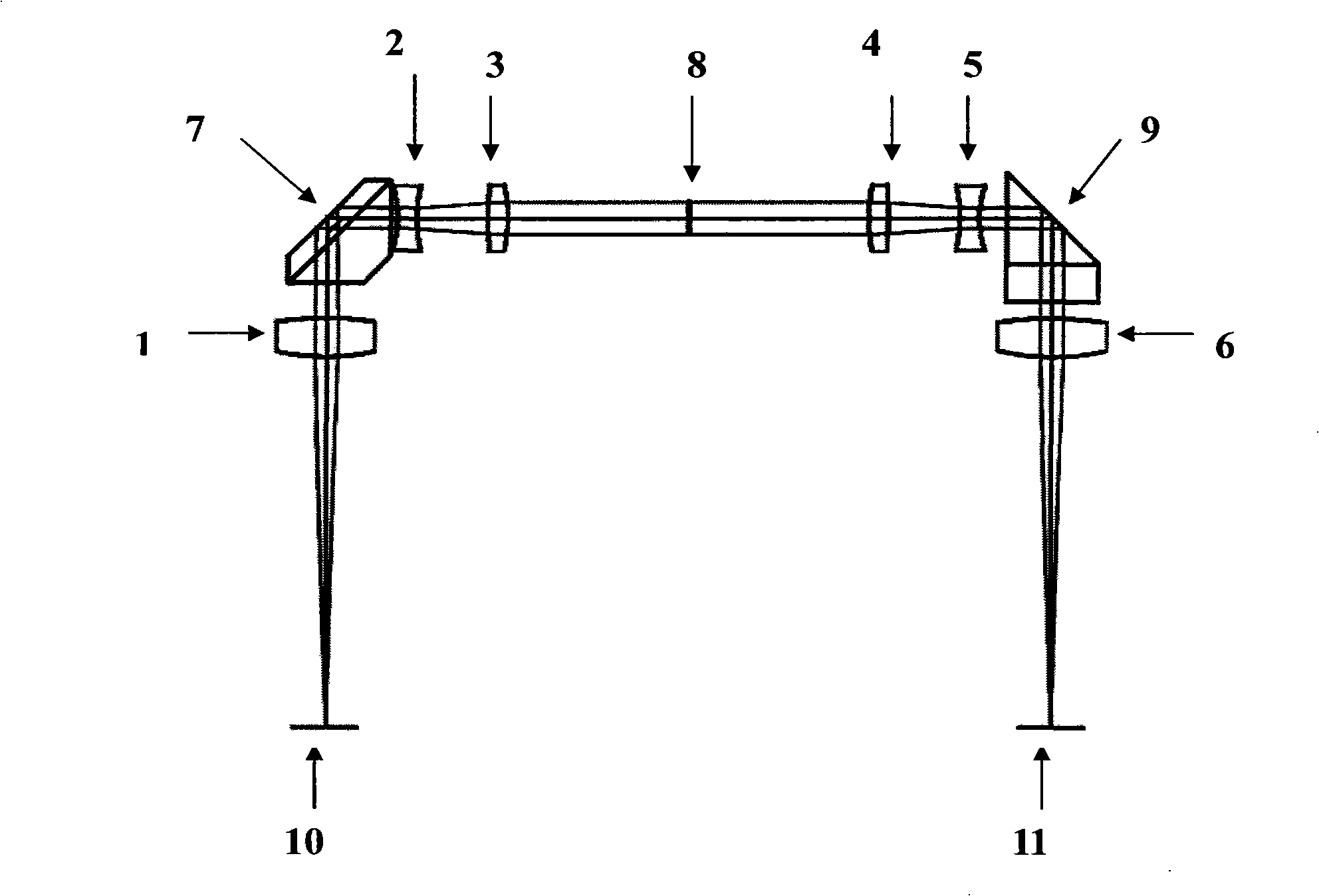

[0016] The structure diagram of the present invention is as figure 1 As shown, it includes an object plane 10 installed in sequence, a first lens 1, a first prism 7 for changing the direction of the object and the image to make the direction of the object and the image consistent, the second lens 2, and the third lens 3 , diaphragm 8, fourth lens 4, fifth lens 5, second prism 9 for changing the direction of object and image, making the direction of object and image consistent, sixth lens 6, image plane 11, wherein the first The lens 1 has the same structure as the sixth lens 6 , the second lens 2 has the same structure as the fifth lens 5 , and the third lens 3 has the same structure as the fourth lens 4 .

[0017] In this embodiment, the above-mentioned first prism 7 is a roof prism. The above-mentioned second prism 9 is a rectangular prism.

[0018] In addition, the middle section of the diaphragm 8 is a parallel optical path, and components such as beam splitters can be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com