ZnO electrode material for hierarchical micro-acceptance structure of dye sensitization solar cell and electrode preparation method

A hierarchical micro-nano structure, solar cell technology, applied in photosensitive devices, electrolytic capacitors, circuits, etc., can solve the problems of restricting the photoelectric conversion efficiency of solar cells, reducing the amount of adsorbed dyes, etc., to increase photon scattering, improve photoelectric conversion efficiency, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

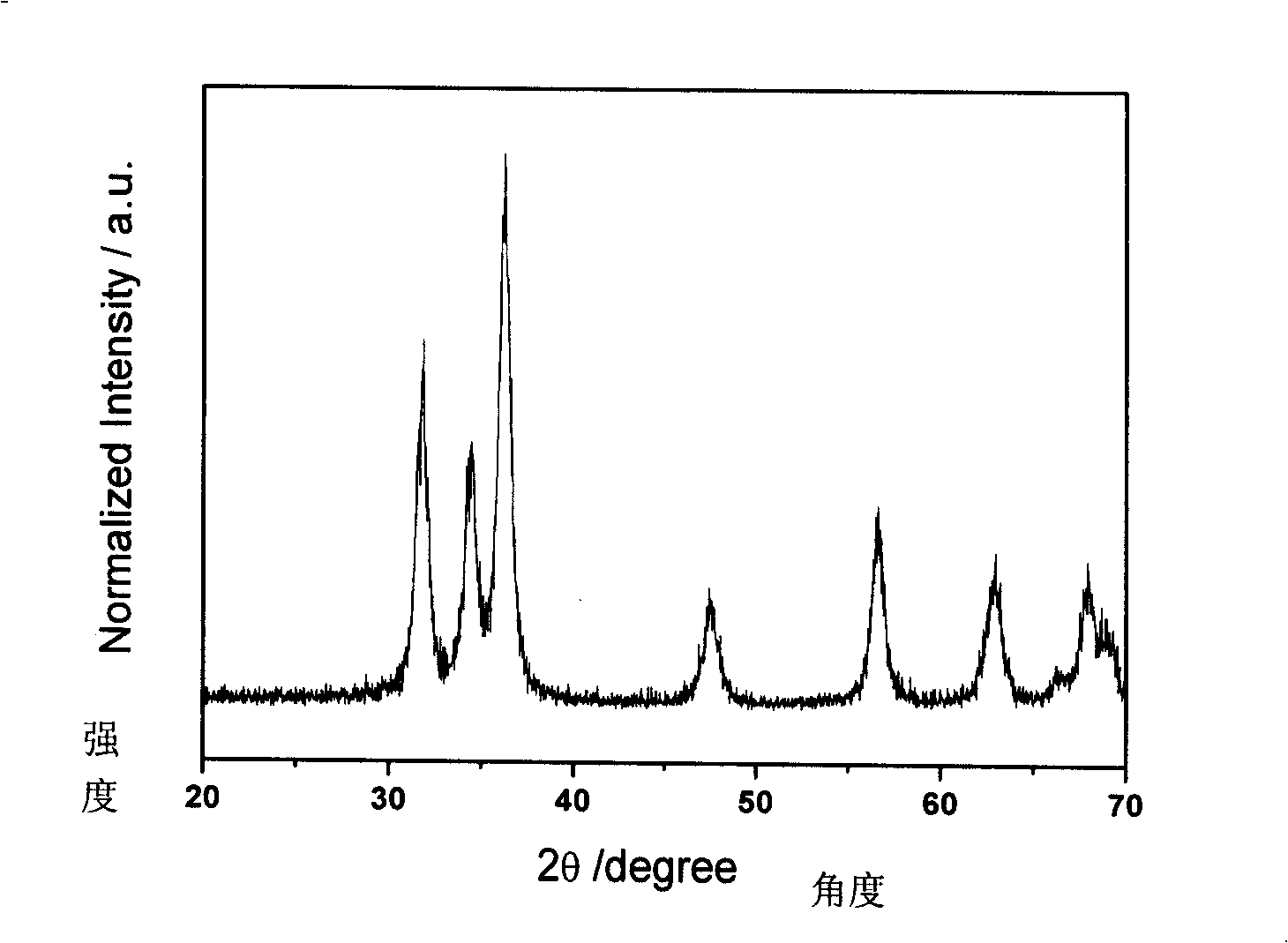

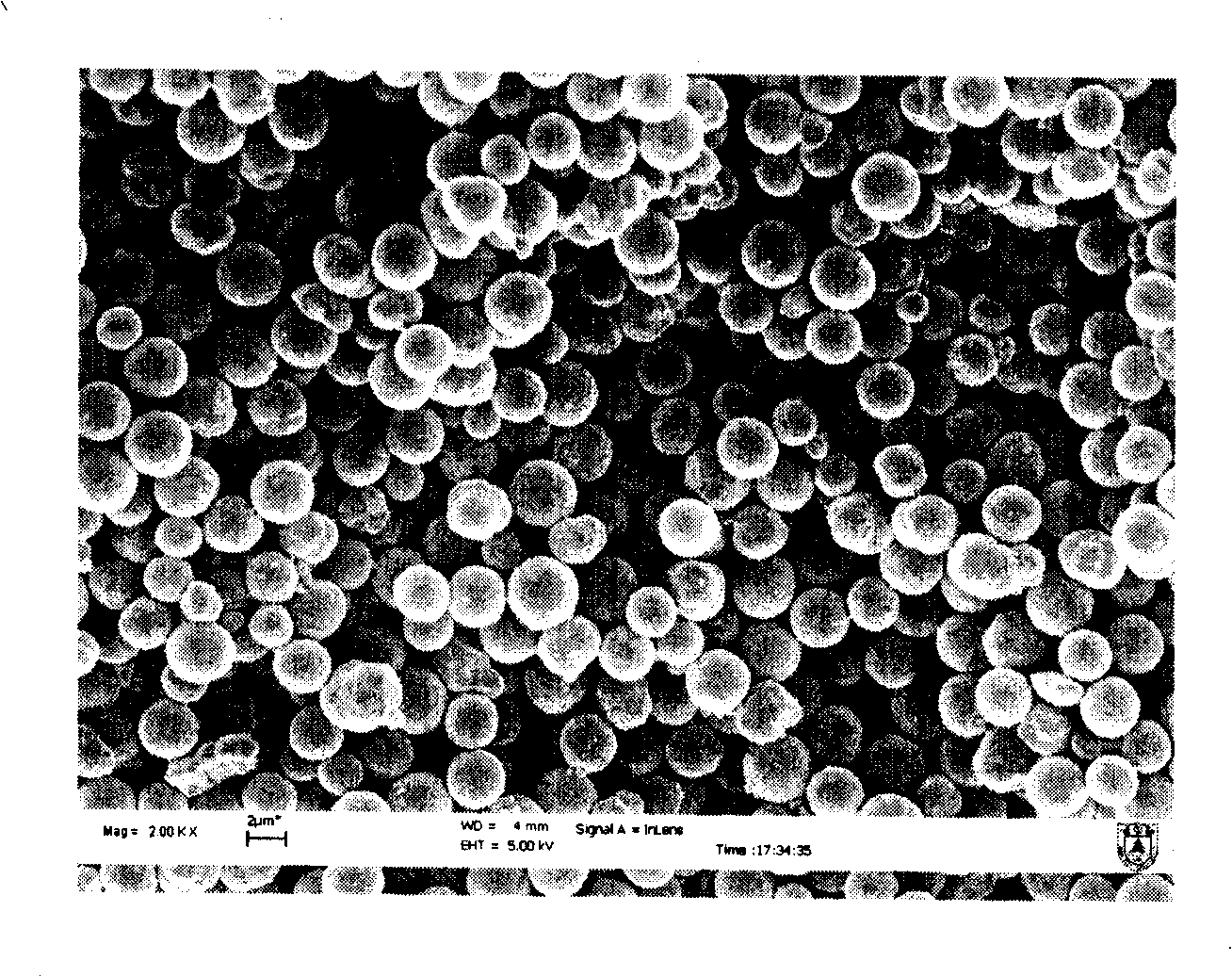

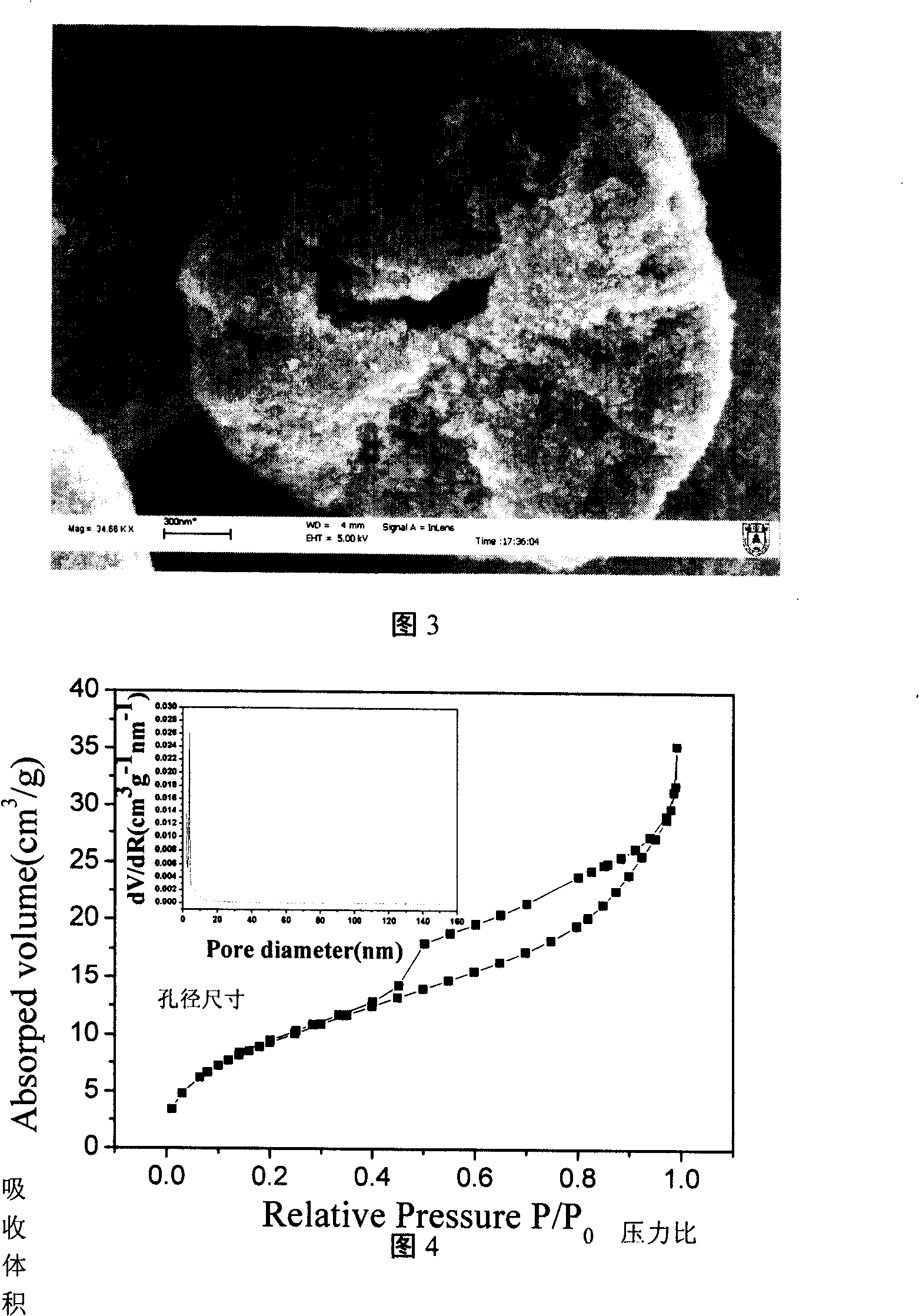

[0025] Put zinc acetate and diethylene glycol into the autoclave at a ratio of 0.3mol / L, the filling volume is 70%, heat up to 160°C at a speed of 5°C / min, and stir at a stirring speed of 200r / min for 8 Hours, after naturally cooling to room temperature, centrifuge, wash with ethanol three times, and dry at 60°C to obtain ZnO powder with hierarchical micro-nano structure. It is mainly composed of 25nm nanoparticles and small balls with a size of 2-3um.

[0026] Take 0.8g of the ZnO powder in 5ml of ethanol, ultrasonically disperse to prepare slurry, and then coat a layer of film on the conductive substrate (FTO) by coating method, after drying, put 0.5mmol / Soak in an ethanol solution of L N719 dye for 4 hours, take out and rinse the excess photosensitizer with ethanol to obtain a dye-sensitized solar cell working electrode.

[0027] The above-mentioned working electrode, platinum electrode, and electrolyte were assembled into a sandwich dye-sensitized solar cell, and its per...

Embodiment 2

[0030] Except that the post-treatment was carried out before soaking the dye (directly put into a horse boiling furnace and baked at 350° C. for 30 min), the rest of the preparation process was the same as in Example 1, and the performance parameter of the obtained dye-sensitized solar cell was J sc (Short-circuit current density) = 3.34mA / cm 2 , V oc (open circuit voltage) = 0.48V, FF (fill factor) = 69%, η (photoelectric conversion efficiency) = 1.08%.

Embodiment 3

[0032] Put zinc acetate and diethylene glycol into the autoclave at a ratio of 0.2mol / L, the filling volume is 70%, heat up to 180°C at a speed of 10°C / min, and stir at a stirring speed of 150r / min for 8 Hours, after naturally cooling to room temperature, centrifuge, wash with ethanol three times, and dry at 60°C to obtain ZnO powder with hierarchical micro-nano structure. It is mainly composed of 20nm nanoparticles and small balls with a size of 500 ~ 1um.

[0033] Take 0.8g of the ZnO powder in 5ml of ethanol, ultrasonically disperse to prepare a slurry, and then coat a thin film on the conductive substrate by coating method, after drying, put 0.3mmol / L N3 while hot at 80°C Soak in the ethanol solution of the dye for 4 hours, take out and rinse the excess photosensitizer with ethanol to obtain the working electrode of the dye-sensitized solar cell.

[0034] The above-mentioned working electrode, platinum electrode, and electrolyte were assembled into a sandwich dye-sensitiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| open-circuit voltage | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com