Nano germanium filter element

A technology of nano-germanium and filter elements, which is applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems of large pH instability, repeated pollution, and inability to use tea together, so as to activate human immune cells, Improve the oxygen carrying capacity of the blood and improve the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The 50-150nm nano-germanium 0.5-0.8% (weight), the 180-200nm tourmaline nano-powder 5-10% (weight), the nano silver antibacterial material 5% (weight), the thermal melting degree is 80-100℃, Viscosity 6000-7500 centipoise, particle size 80-120 mesh hot-melt powder polyamide (PA) 8-10% (weight), and the balance 40-60 mesh activated carbon is added to the mixing box of the screw pump, while stirring, mixing 4 After -6 minutes, it is extruded into a filter-shaped forming die at one end, and then shaped at a high temperature of 80-100 DEG C for 30 seconds to 1 minute to obtain the cylindrical nano-germanium filter element of the present invention. The formed cylindrical nano-germanium filter element has a porosity of 300-350 nm.

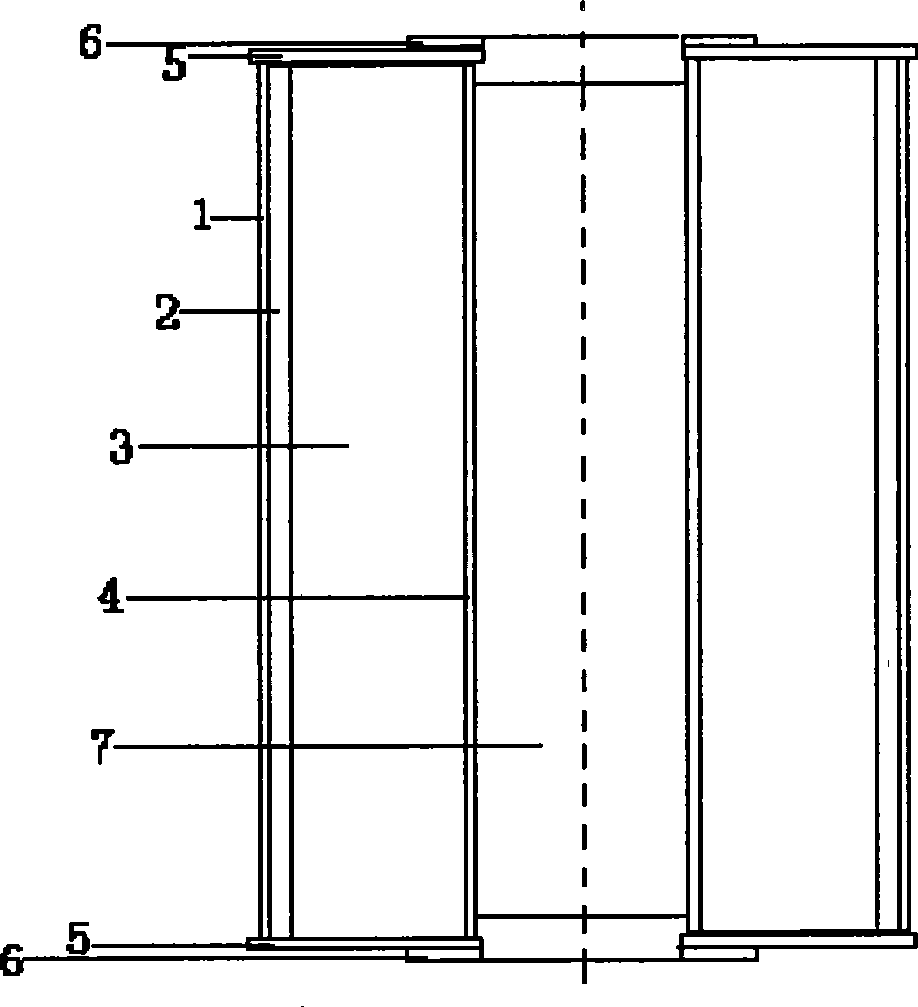

[0043] The filter element is covered with an outer non-woven fabric protective layer 2, and the outermost periphery is covered with a non-woven part or a polypropylene mesh outer protective net 1. The inner water-passing cavity of the filter element i...

Embodiment 2

[0045] The components of the cylindrical nano-germanium filter element material in this embodiment are: 150-200nm nano-germanium 0.8-1.2% (weight), 200-300nm tourmaline nano-powder 10-15% (weight), nano-silver antibacterial material 3 % (Weight), hot melt at 80-100℃, viscosity 5000-5500 centipoise, particle size 100-120 mesh hot-melt powder polyester amide (PEA) 10-15% (weight), and 70% (weight) 60 -80 mesh activated carbon. The formed cylindrical nano-germanium filter element has a porosity of 300-400 nm. The rest of the implementation is the same as in Example 1.

Embodiment 3

[0047] The components of the nano-germanium filter element of this embodiment are: 250-300nm nano-germanium 1.2-2% (weight), 300-400nm tourmaline nano-powder 15-20% (weight), nano-silver antibacterial material 2.5% (weight) , Hot melt powdered polyethylene (CDPE) 15-20% (weight) with a hot melt degree of 100-120°C, a viscosity of 3000-3500 centipoise, a particle size of 100-120 mesh, and 60% (weight) of activated carbon with 40-60 mesh. The formed cylindrical nano-germanium filter element has a porosity of 400-500 nm. The rest of the implementation is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com