Dicyclopentadiene type ethylene rhodanate resin and preparation thereof

A dicyclopentadiene type cyanate ester and resin technology, applied in the field of modified dicyclopentadiene type cyanate resin and its preparation, can solve the problem of GMA and bismaleimide copolymer application research. Various reports and other issues, to achieve the effect of improving manufacturability, improving heat resistance and mechanical properties, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Prepolymerize 5 parts of GMA and 5 parts of 4,4'-diaminodiphenylmethane bismaleimide at 120°C for 3 hours, then raise the temperature to 140°C for 5 hours to obtain GMA / BMI prepolymer. Add the prepolymer and 0.05 parts of dibenzoyl peroxide into 90 parts of DCPDCE, and stir thoroughly at 85° C. to obtain the modified dicyclopentadiene type cyanate resin.

Embodiment 2

[0017] Prepolymerize 5 parts of GMA and 10 parts of 4,4'-diaminodiphenylmethane bismaleimide at 130°C for 2.5 hours, then raise the temperature to 150°C for 4 hours to obtain a GMA / BMI prepolymer. Add the prepolymer and 0.07 parts of dibenzoyl peroxide into 85 parts of DCPDCE, and stir thoroughly at 75°C to obtain a modified dicyclopentadiene type cyanate resin.

Embodiment 3

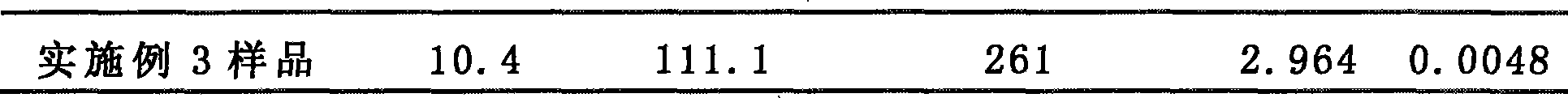

[0019] Prepolymerize 5 parts of GMA and 15 parts of 4,4'-diaminodiphenylmethane bismaleimide at 140°C for 2 hours, then raise the temperature to 150°C for 5 hours to obtain a GMA / BMI prepolymer . Add the prepolymer and 0.1 part of azobisisobutyronitrile into 80 parts of DCPDCE, and stir thoroughly at 80°C to obtain a modified dicyclopentadiene type cyanate resin.

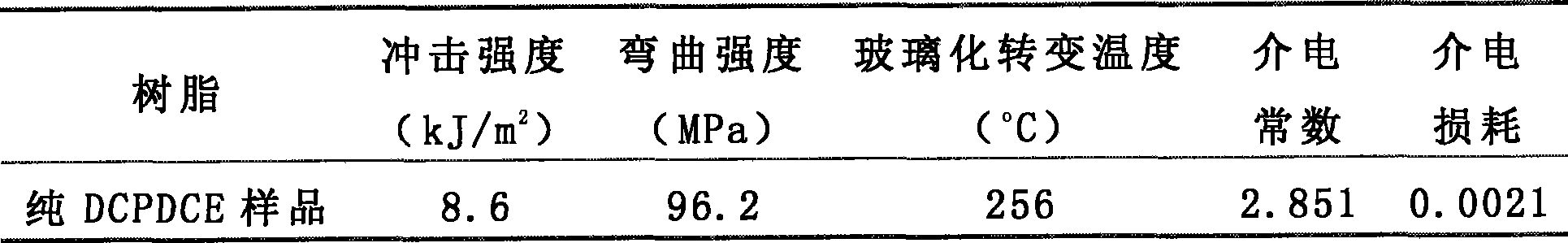

[0020] The resin is cured and post-treated according to the process of 160°C / 2h+180°C / 1h+200°C / 1h+230°C / 3h. The typical properties of the obtained cured resin are shown in Table 1.

[0021] Prepare pure dicyclopentadiene type cyanate (DCPDCE) cured resin sample as a comparative example: 100 parts of DCPDCE and 0.1 part of azobisisobutyronitrile are fully stirred at 80°C, according to 160°C / 2h+180°C / 1h +200°C / 1h+230°C / 3h process for curing and post-treatment to obtain pure DCPDCE cured resin, and its typical properties are listed in the pure DCPDCE sample in Table 1.

[0022] Table 1: Performance comparison between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com