Flat-shaped groove heat exchange tube and heat exchanger using the same

A technology of heat exchange tubes and flat shapes, which is applied in the field of heat exchangers of exhaust gas recirculation coolers, can solve the problems of reduced heat exchange efficiency of heat exchangers, achieve improved heat exchange effects, increase reliability, and reduce maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

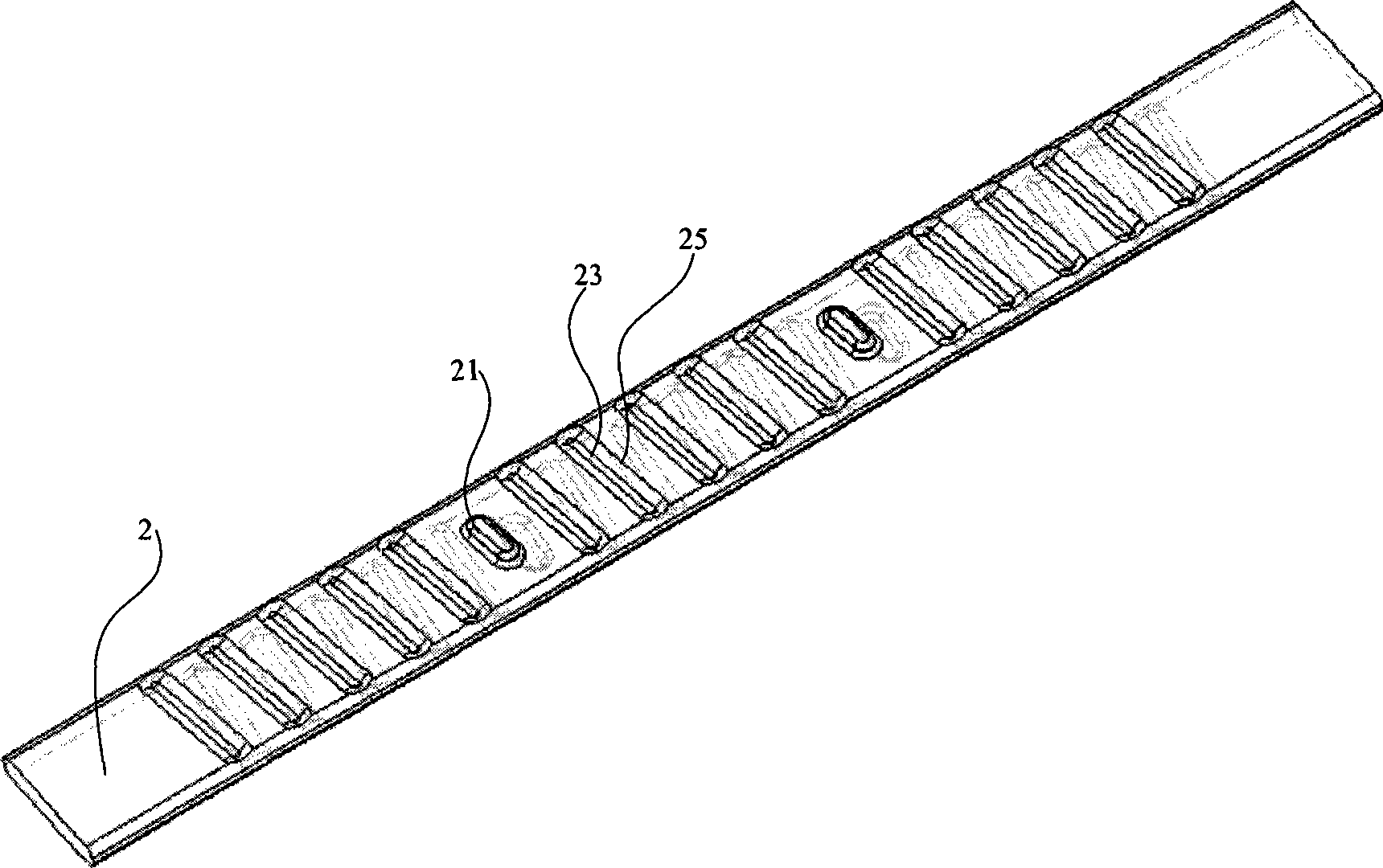

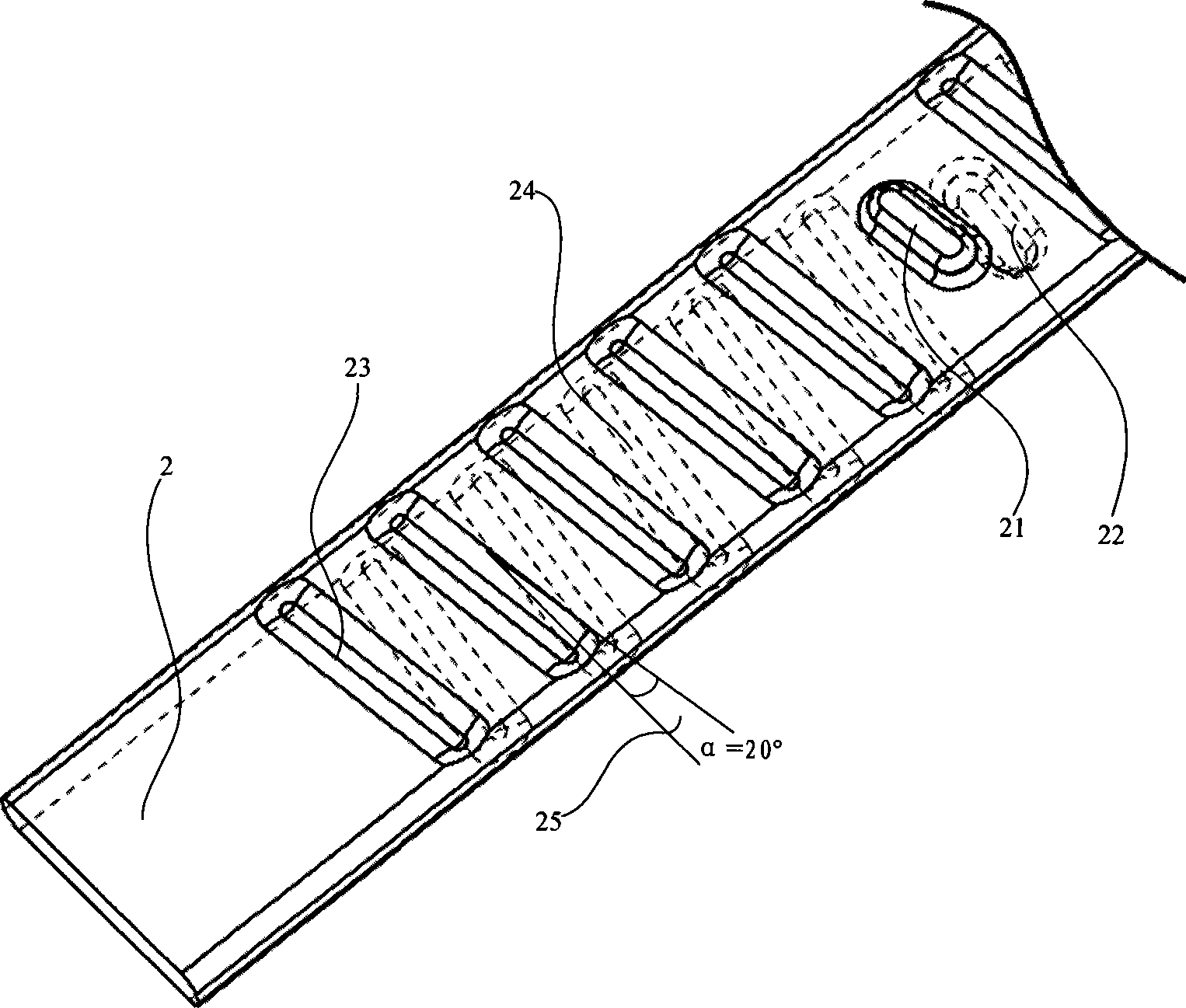

[0033] This embodiment is a flat groove heat exchange tube, which includes a stainless steel tube body with a cross-sectional shape of different height and width. The upper and lower surfaces between the grooves are provided with outwardly protruding bulges.

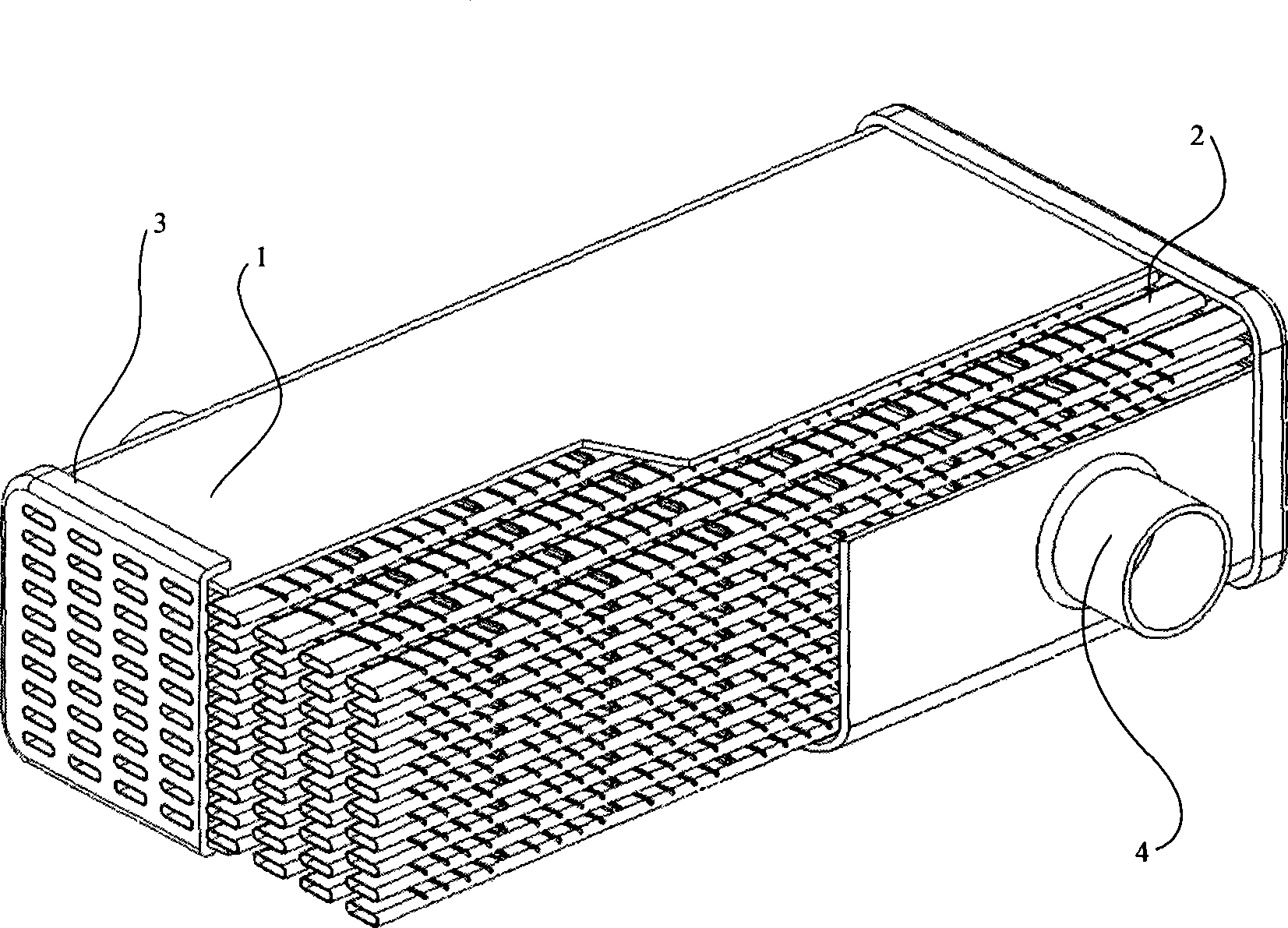

[0034] see figure 1 , figure 2 and image 3 , figure 2 is a perspective view of a flat grooved heat exchange tube with a cross-sectional shape, image 3 It is a partial enlarged view of the flat heat exchange tube, figure 1 It is a heat exchanger using flat heat exchange tubes. The heat exchanger is mainly composed of a shell 1, a heat exchange tube 2, a tube sheet 3 and a water tube 4. The tube plates at both ends of the casing are provided with recirculation exhaust gas inlet and exhaust gas outlet, and the casing is provided with coolant inlet and coolant outlet. The cross-section of the heat exchange tube is a rectangle with different long sides and short sides. The upper and lower surfaces of the tube body ...

Embodiment 2

[0036] This embodiment is an improvement of Embodiment 1. The spacing of the short grooves in this embodiment is equal, and the axes of all the short grooves on the pipe body along the long side are connected together to form a continuous equal-pitch around the pipe body. spiral, such as figure 2 , 3 shown.

[0037] The equidistant helix is similar to the helix on the existing continuous helical groove heat exchange tube, such as Figure 4 shown. Figure 4 Shown is a perspective view of a flat continuous spiral grooved heat exchange tube, which also has the effect of strengthening the flow of fluid inside and outside the tube, but compared with the flat grooved tube in the present invention, it lacks a tube body The bulge on the top is set, so that when it is arranged in the heat exchanger, there is no support between the tubes, and there may be a situation where the flat tube is deformed at high temperature, which may lead to a decrease in the heat exchange effect. The ...

Embodiment 3

[0040] This embodiment is an improvement of the second embodiment. In this embodiment, the helix angle of the axis of the short groove along the long side direction ranges from 15° to 30°.

[0041] In this embodiment, the helix angle 25 of the short grooves 23, 24 is between 15° and 30°. The depth of the short grooves 23, 24 is not less than 0.4 mm. For example, when the lengths of the long and short sides of the flat tube are 13.5 mm and 4 mm respectively, and the wall thickness is 0.3 mm, the depth of the short groove can be several different values such as 0.6 mm, 0.8 mm, 1.0 mm, and 1.2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Protruding height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com