Method for light inducing light refraction change crystal surface microstructure

A technology of photorefractive crystals and microstructures, applied in optics, nonlinear optics, instruments, etc., can solve the problems of complex operation, unfavorable surface microstructure formation, unfavorable popularization and application, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

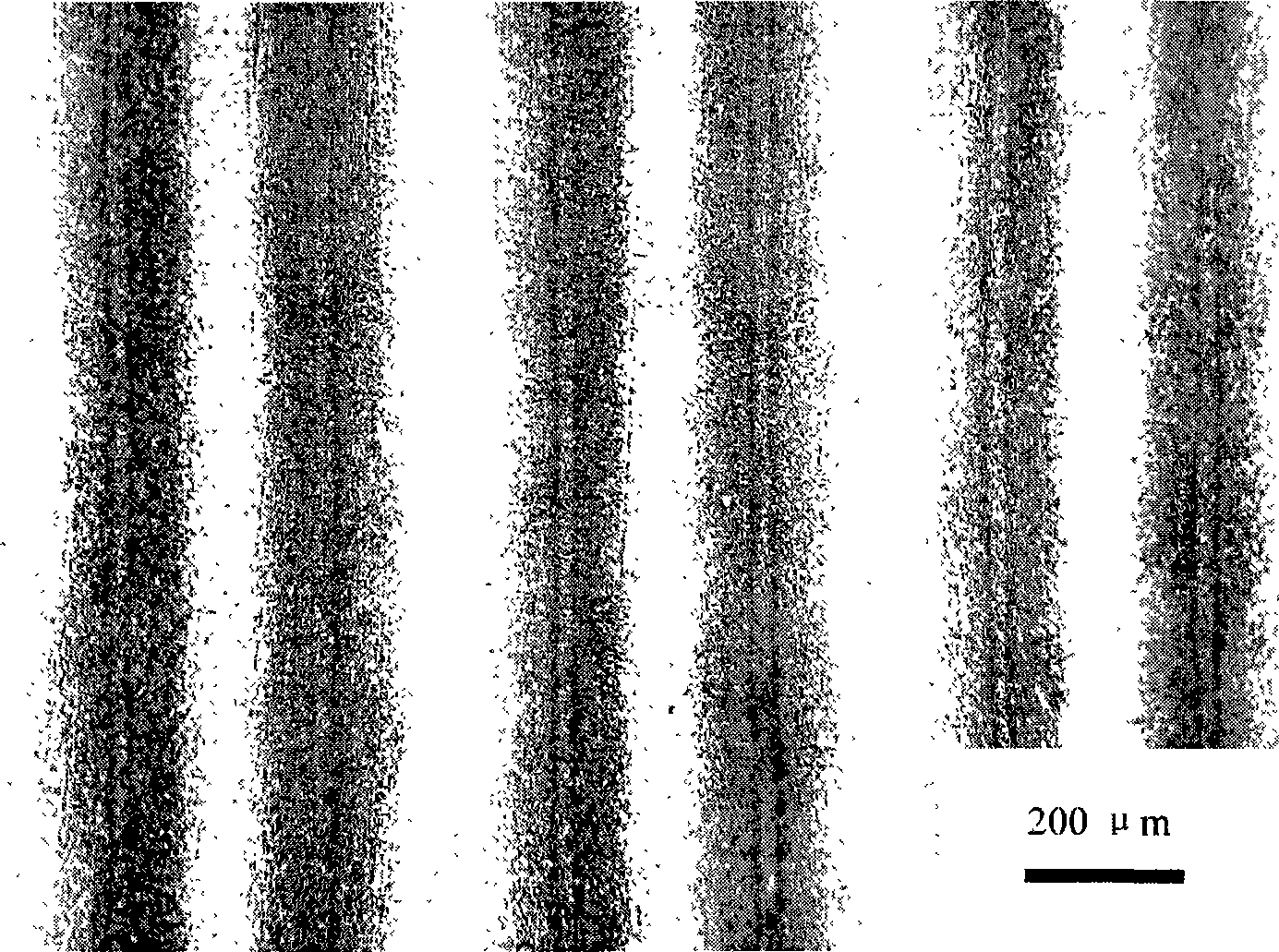

[0058] For the present invention, nano-silver powder is used as micro-nano particles, the average particle diameter of which is 50nm, and the silver particle grid is constructed on the surface of lithium niobate crystal by dielectrophoretic effect, and uncharged silver metal micro-nano particles are formed under the action of dielectrophoretic force Surface microstructure, the surface microstructure such as figure 1 shown;

Embodiment 2

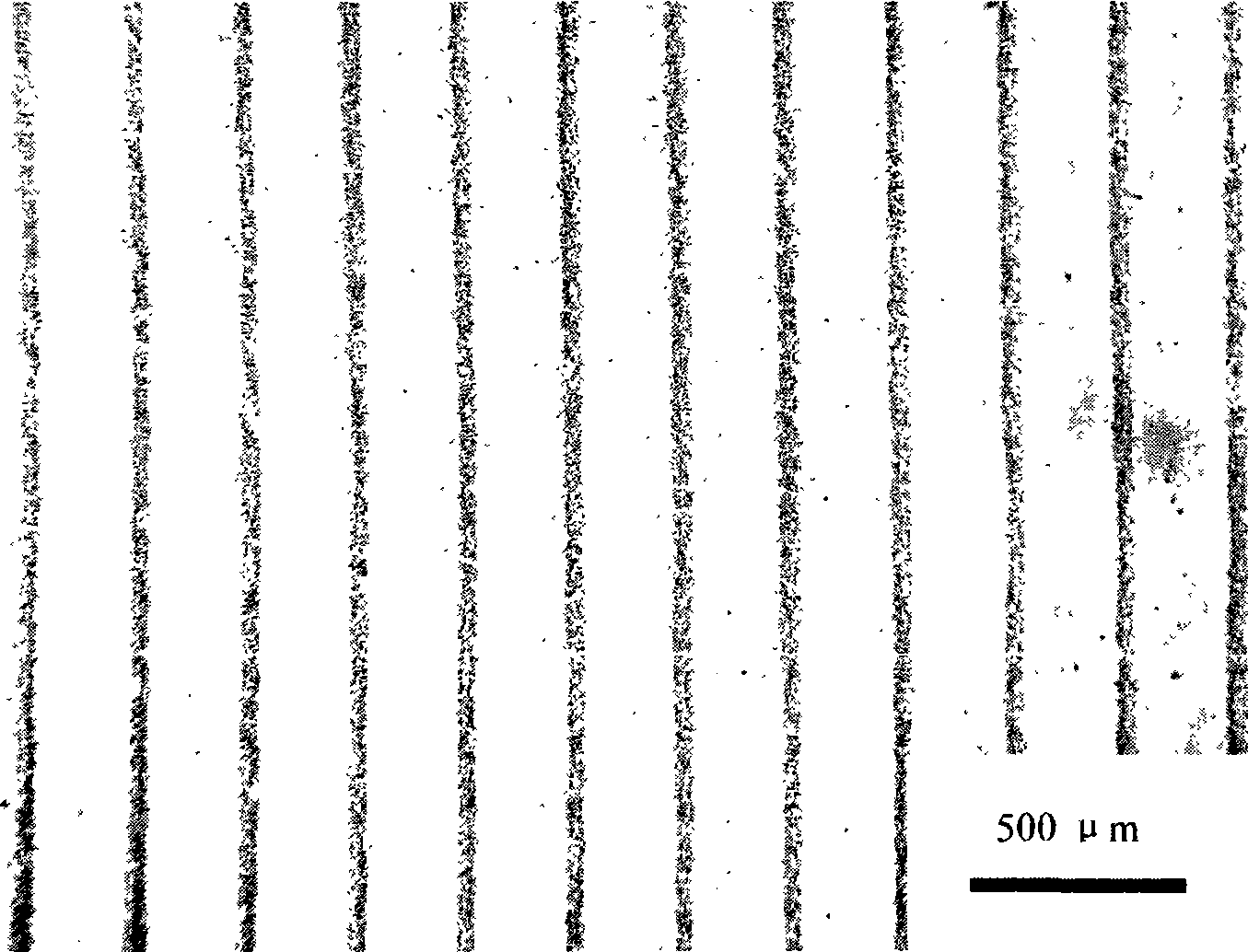

[0060] For the present invention, the spherical metal aluminum powder particles are adopted as micro-nano particles, and the median diameter of the particles is 1.52 microns, so the electrophoretic effect is used to construct aluminum particle grids on the lithium niobate crystal surface, and the positively charged aluminum metal micro-nano particles Under the action of electrophoretic force, the surface microstructure is formed, such as figure 2 shown;

Embodiment 3

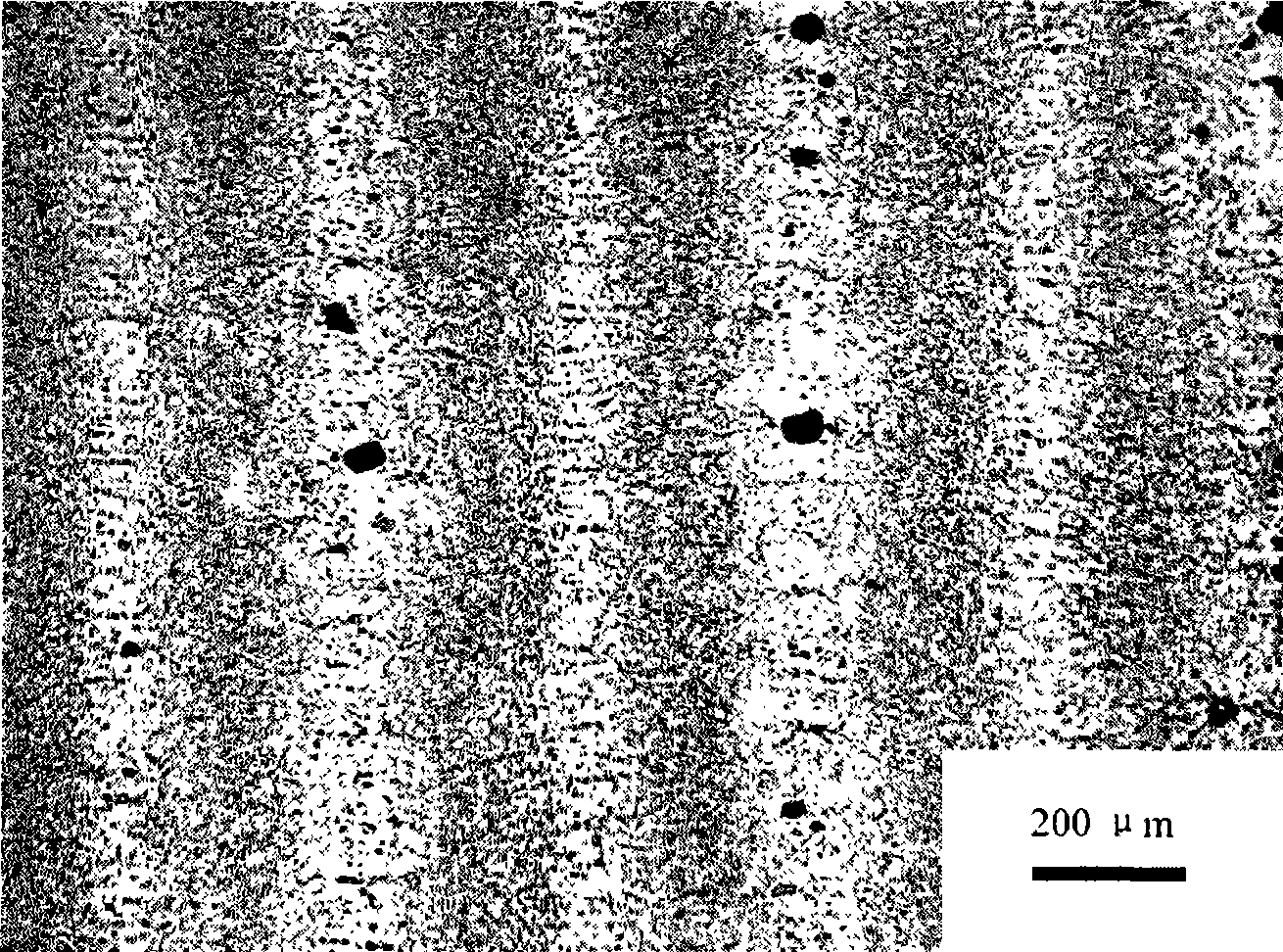

[0061] Example 3: Titanium dioxide particles are used as micro-nano particles, then the dielectrophoretic effect is used to construct a titanium dioxide grid on the surface of lithium niobate crystals, and the uncharged non-metallic micro-nano particles form a surface microstructure under the action of dielectrophoretic force. structured as image 3 shown;

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com