Radiation sensitive composition for forming a colored layer, color filter and color liquid crystal display device

A radiation-sensitive technology that is applied in the field of radiation-sensitive compositions to achieve excellent adhesion and excellent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

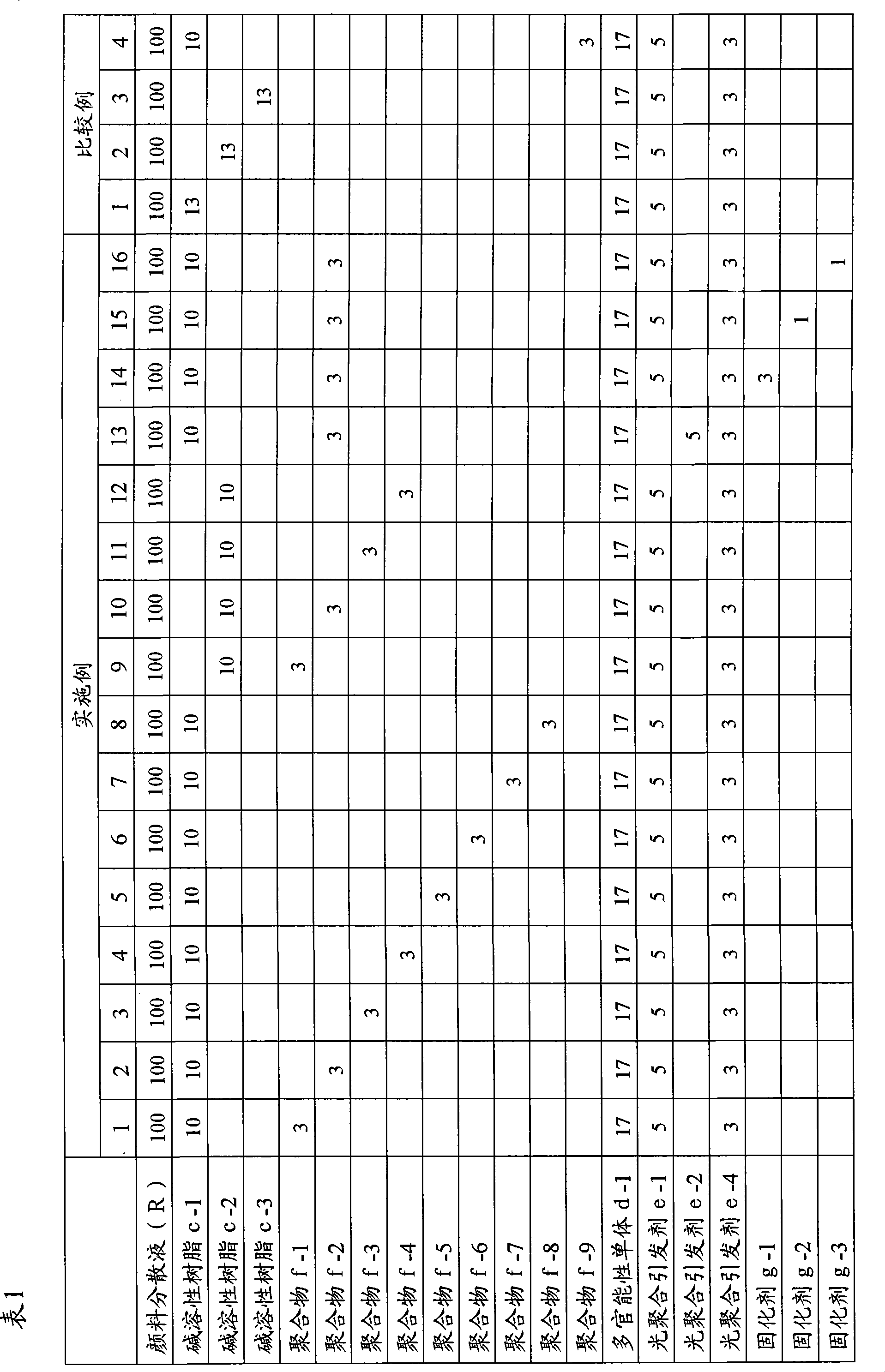

[0338] Hereinafter, examples are given to further specifically describe the present invention. However, the present invention is not limited to the following examples. The following "parts" and "%" are mass standards unless otherwise indicated.

[0339] Mw and Mn of the resins obtained in the following synthesis examples were measured by the following gel permeation chromatography (GPC).

[0340] Device: GPC-101 (manufactured by Showa Denko Co., Ltd.)

[0341] Column: Combined use of GPC-KF-801, GPC-KF-802, GPC-KF-803 and GPC-KF-804

[0342] Elution solvent: THF with 0.5% phosphoric acid

[0343] The dispersant, polyfunctional monomer, photopolymerization initiator, and curing agent used in this example are as follows.

[0344] Dispersant

[0345] b-1: Disperbyk-2001 (non-volatile content = 46%, amine value = 29, acid value = 19, manufactured by ビツクケミー(BYK) Co., Ltd.)

[0346] b-2: Solspa-su 24000 (non-volatile content = 100%, amine value = 42, acid value = 25, manufac...

Synthetic example 1

[0362] Add 3 parts of 2,2'-azobisisobutyronitrile, 200 parts of propylene glycol monomethyl ether acetate into a flask equipped with a condenser tube and a stirrer, then add 15 parts of methacrylic acid, 20 parts of N-phenylmethane Laimide, 10 parts of styrene, 55 parts of benzyl methacrylate, and 5 parts of 2,4-diphenyl-4-methyl-1-pentene (trade name Nofma-MSD manufactured by NOF Co., Ltd. ) as a molecular weight regulator, nitrogen substitution. Thereafter, the mixture was stirred slowly to raise the temperature of the reaction solution to 80° C., and the temperature was kept at this temperature for 5 hours to perform polymerization, thereby obtaining a resin solution. This resin is referred to as "alkali-soluble resin (c-1)". The polystyrene-equivalent weight-average molecular weight measured by gel permeation chromatography of this alkali-soluble resin was 11,000, and Mw / Mn was 2.6.

Synthetic example 2

[0364]Add 3 parts of 2,2'-azobisisobutyronitrile, 200 parts of propylene glycol monomethyl ether acetate, followed by 15 parts of methacrylic acid, 85 parts of benzyl methacrylate in a flask equipped with a condenser and a stirrer , and 5 parts of 2,4-diphenyl-4-methyl-1-pentene (trade name Novoma-MSD manufactured by NOF Co., Ltd.) as a molecular weight regulator, nitrogen substitution. Thereafter, the mixture was stirred slowly to raise the temperature of the reaction solution to 80° C., and the temperature was kept at this temperature for 5 hours to perform polymerization, thereby obtaining a resin solution. This resin is referred to as "alkali-soluble resin (c-2)". The alkali-soluble resin had a polystyrene-equivalent weight-average molecular weight of 13,000 as measured by gel permeation chromatography, and Mw / Mn of 28.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com