Method for designing recycle hydrogen heating furnace gas pressure safe instrument system

A safety instrumented system, gas pressure technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of insufficient flexibility, immature development, and low accuracy of quantitative analysis of reliability, etc., to achieve quantitative analysis High precision, easy daily maintenance, and good calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

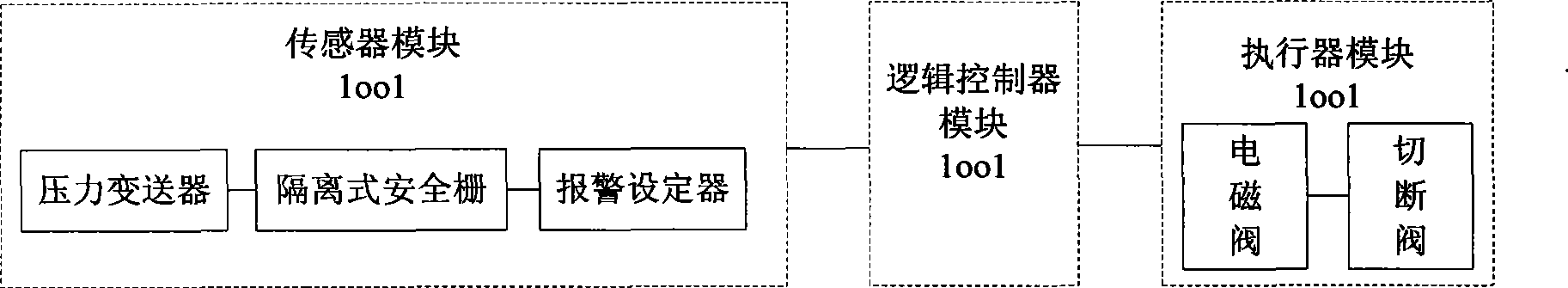

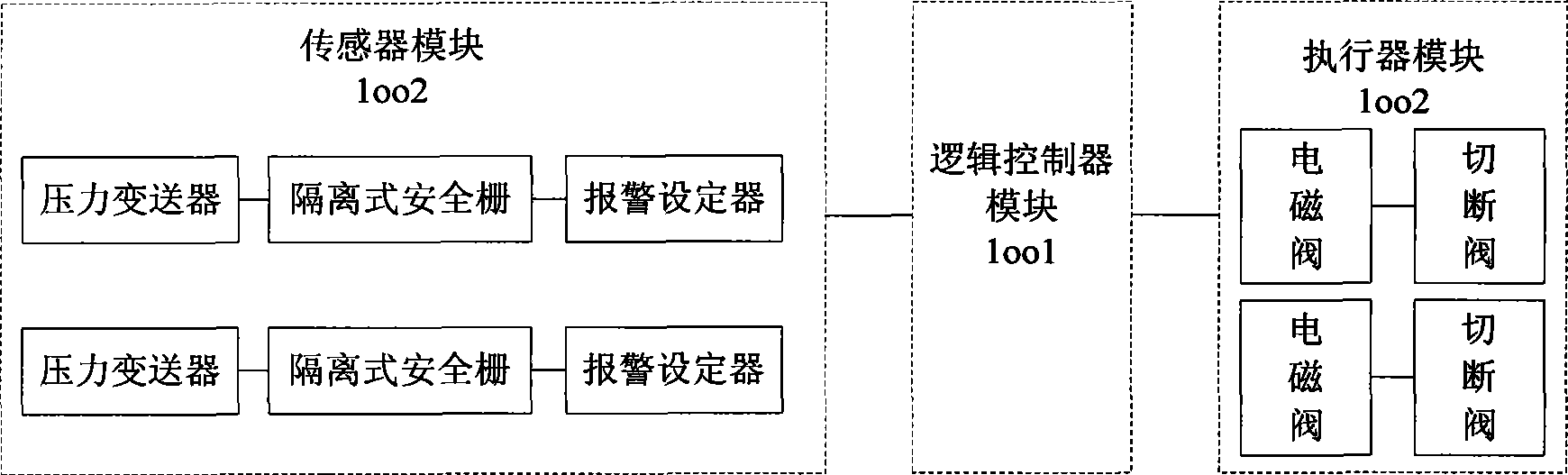

[0037] Such as figure 1 As shown, the safety instrumented system before improvement consists of sensors, logic controllers and actuators. The sensor part includes pressure transmitter PT3108, isolated safety barrier PBI3108, and alarm setter PA3108. The pressure transmitter detects the gas pressure, and the signal passes through the safety barrier installed in the control room to the alarm. The alarm setter divides the signal into two channels: one analog flow signal goes to the DCS system to participate in process control; one switch signal goes to the Logic controller, which participates in the control of safety instrumented functions. The logic controller selects a dedicated safety PLC system. After logic operation processing, the output switch signal is transmitted to the on-site solenoid valve, and the solenoid valve closes the regulating valve through the change of the gas circuit, cutting off the fuel gas. From the flow of the entire signal, it can be seen that the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com