Axial plunger pump or motor

An axial piston pump and motor technology, applied in the field of hydraulic pump or motor device, can solve the problems of complex structure and process, high cost, large size, etc., to achieve improved oil absorption performance, reduced oil filtration accuracy requirements, friction and The effect of leakage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

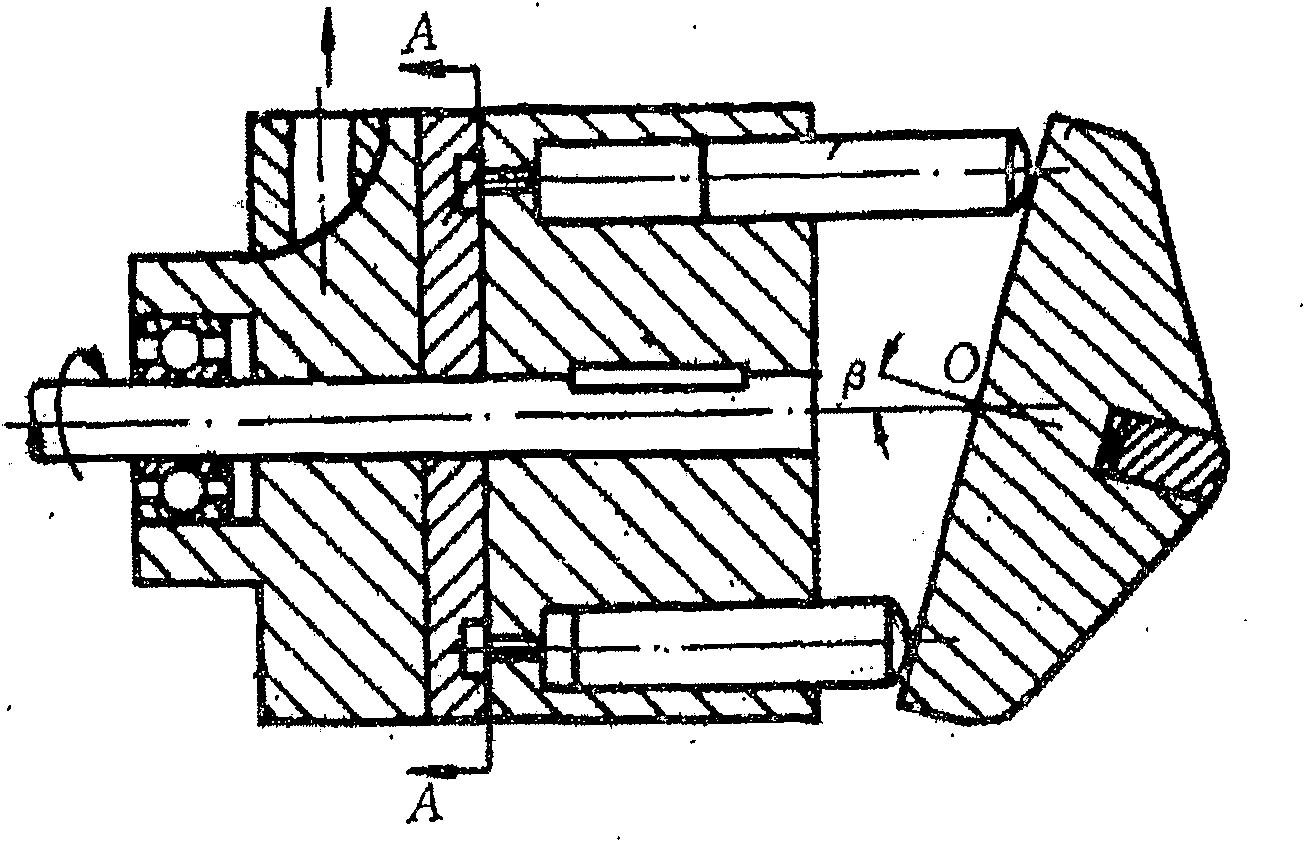

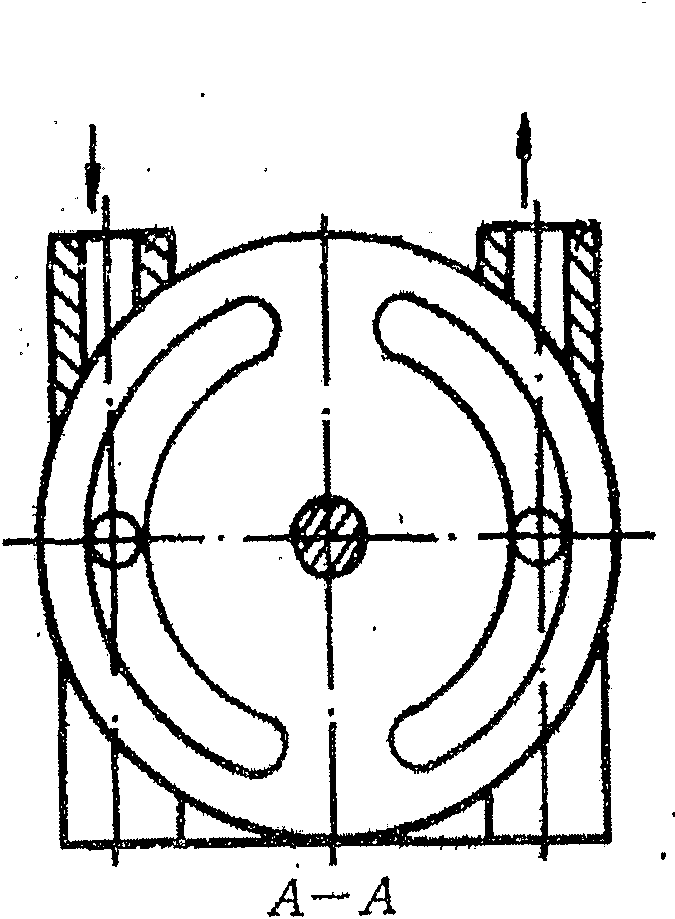

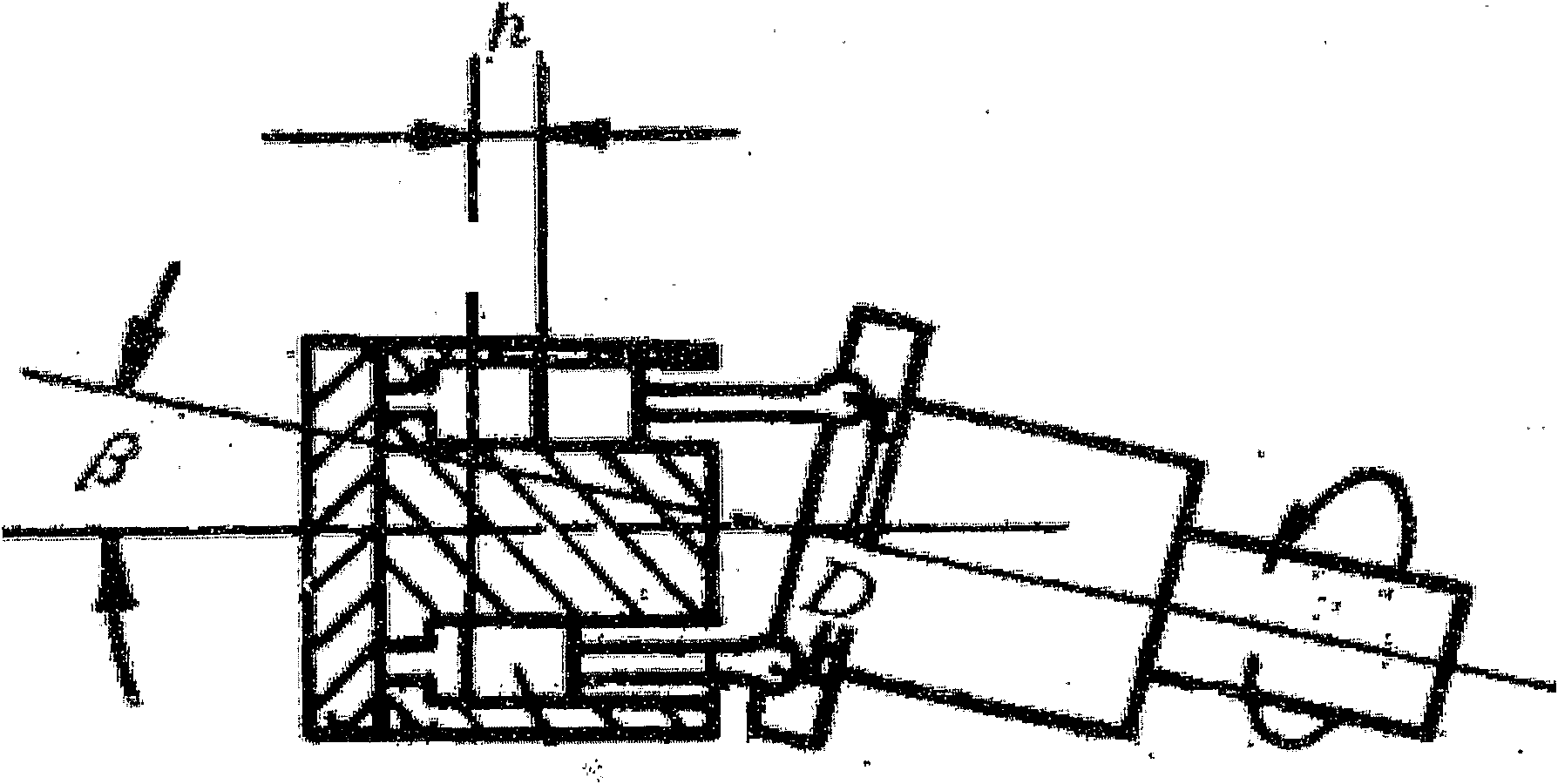

[0056] see Figure 4 As shown, the axial piston pump or motor of the present invention mainly includes: a housing 1; a main shaft 4, which is rotatably supported on the housing 1; a rotor cylinder 14 with a plurality of plunger holes, which is combined on the main shaft 4 , which is driven by the main shaft 4 to rotate around the main shaft axis 41, and the rotor cylinder 14 has an oil distribution end face; the oil distribution plate 15 is matched with the oil distribution end face of the rotor cylinder 14; A plurality of plunger holes of the cylinder body 14 are arranged axially opposite to each other, and can rotate around the swash plate axis 91 forming an angle with the main shaft axis 41; a plurality of plunger assemblies 10, one end of which is hinged on the end surface of the swash plate 9 , the other end is slidingly set in the plunger hole of the rotor cylinder 14; the constant velocity universal joint 11 is set between the swash plate 9 and the main shaft 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com