Preparation method of ultra light porous metal fiber sandwich board

A porous metal and sandwich panel technology, which is applied in the field of preparation of ultra-light porous metal fiber sandwich panels, can solve the problems of difficult implementation, complex preparation process, low bonding strength of porous metal fiber core and panel, and achieve light weight , the effect of high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

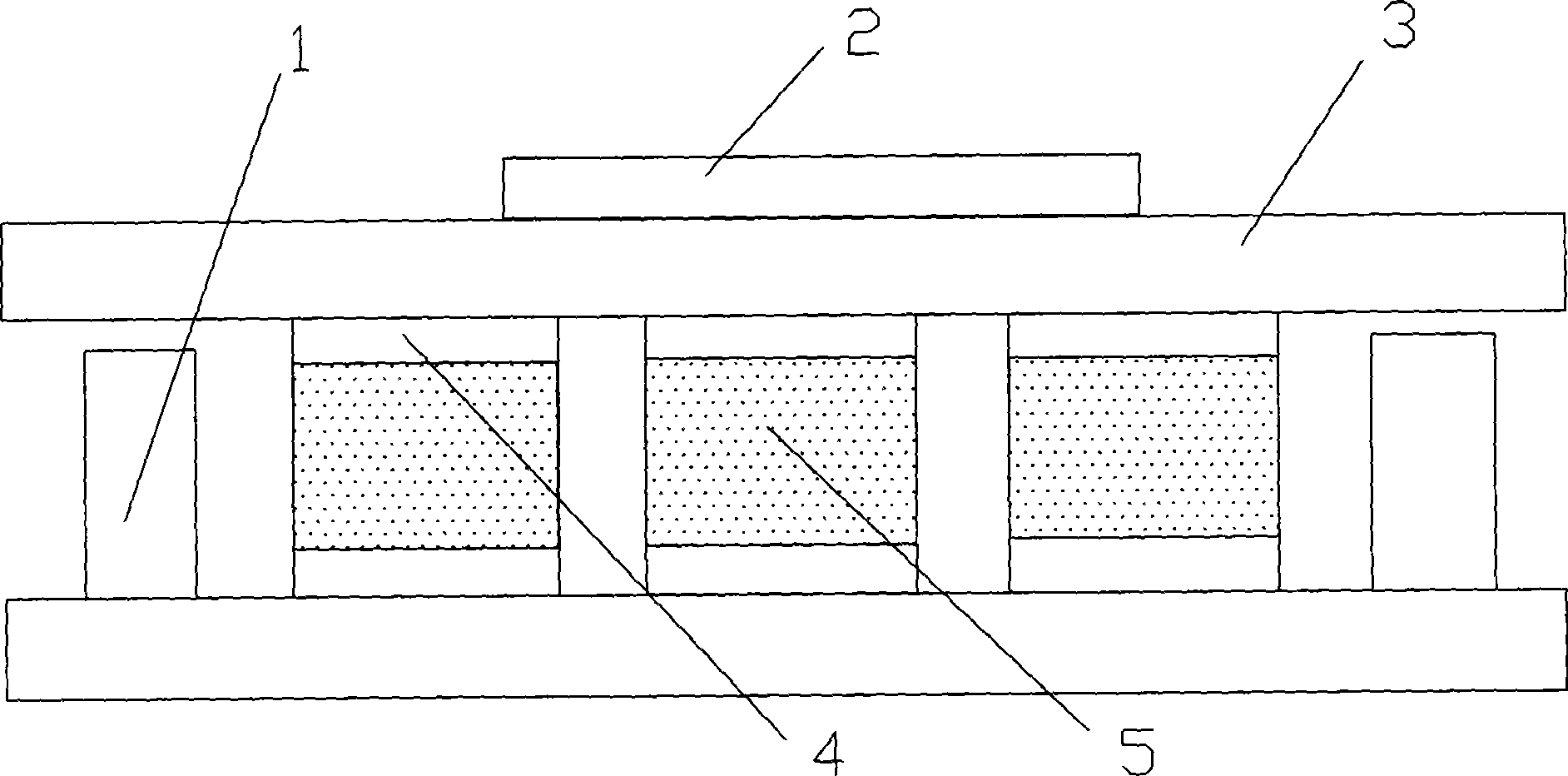

Embodiment 1

[0028] A 316L stainless steel plate with a size of 150mm×150mm and a thickness of 0.4mm was cut as the metal panel 4, and the surface oil was removed in an aqueous solution of metal detergent, and the surface oxide layer was removed with sandpaper with a particle size of 80 mesh, and roughened. Coat a layer of ultrafine stainless steel powder polyvinyl alcohol suspension with a concentration of 5% on the treated panel. The sintered porous metal fiber core body 5 with a thickness of 12 mm and a porosity of 83.5% is sandwiched between two panels coated with a sintered activation layer to ensure that the two panels are parallel. The sandwich sandwich panel to be sintered is dried in an oven to form a metal fiber sandwich structure green body. The green body is in the sintering process: the temperature is 1210°C, the holding time is 2h, and the vacuum degree is kept at 1.5×10 -2 Above Pa. The sandwich sintered green body is placed between two 8mm thick heat-resistant steel plate...

Embodiment 2

[0030] A porous fiber material with a thickness of 5 mm and a design porosity of 70% was prepared by air-laid 304 stainless steel fiber porous blank with a wire diameter of 8 μm as an unsintered porous metal fiber core. Cut the 316 stainless steel plate with a thickness of 1mm, brush the surface oil in the metal detergent solution, remove the surface oxide layer with 3% hydrochloric acid solution, and use a knife to carve the surface to create a rough surface. On the treated stainless steel metal panel 4, a layer of ultrafine stainless steel powder methylcellulose suspension with a concentration of 10% is coated. The above-mentioned porous metal fiber core body 5 is sandwiched between two stainless steel metal panels 4 coated with a sintered activation layer to ensure that the two stainless steel metal panels 4 are parallel. The sandwich sandwich panel to be sintered is dried in an oven to form a metal fiber sandwich structure green body. The green body is in the sintering pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com