Method for separating fluorine hydride from 1,1-difluoroethane production

A technology of difluoroethane and hydrogen fluoride, applied in the field of separation, can solve the problems of high energy consumption, consumption of industrial water and lye, high cost, and achieve the reduction of consumption of rectification system, reduction of use and replacement, and low water content of products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Ethylenediamine is used as the liquid amine absorbent.

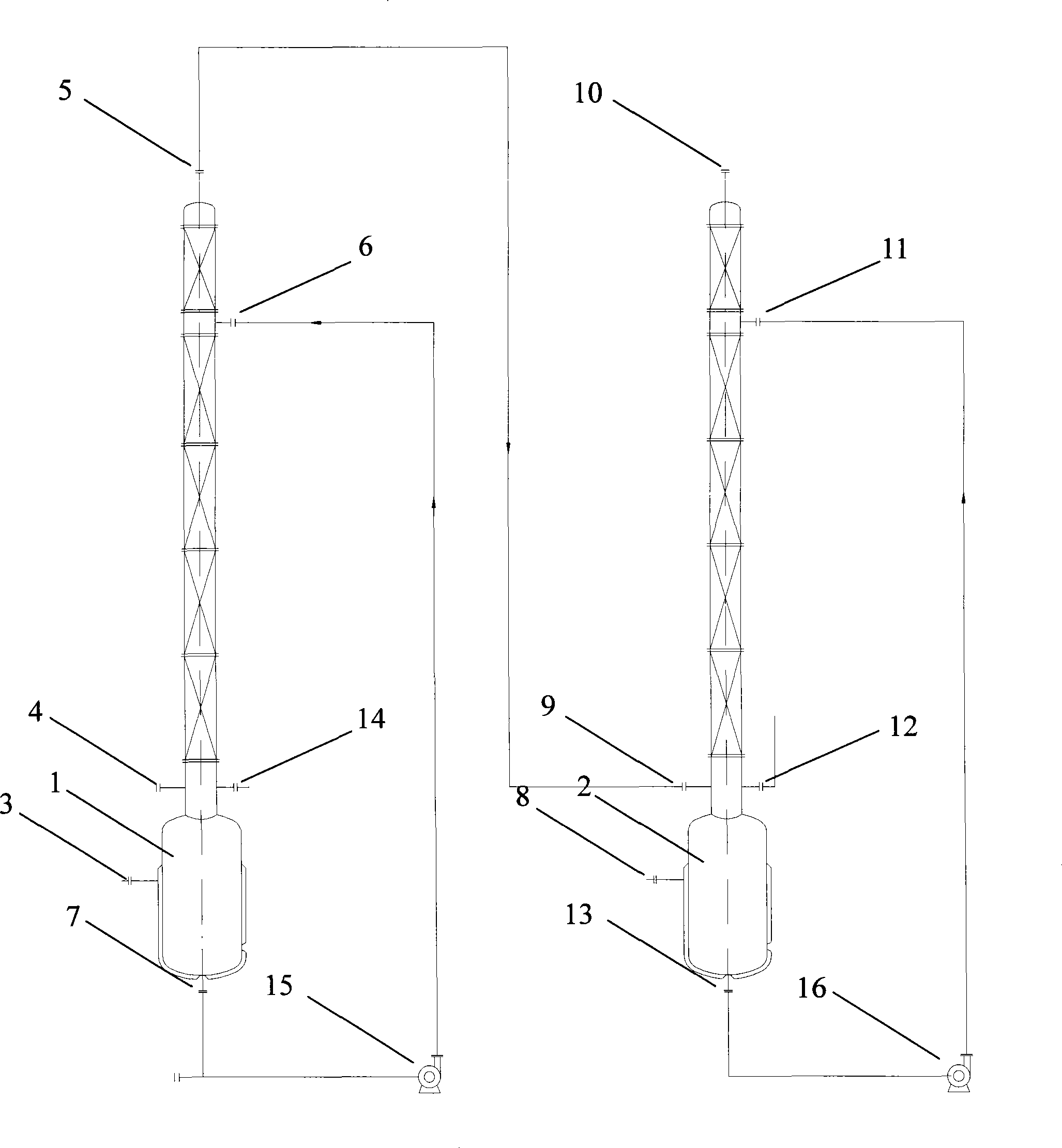

[0023] In the method for separating hydrogen fluoride in the production of 1,1-difluoroethane provided by Example 1 of the present invention, open the absorbent feed port (14), put a certain amount of absorbent in the tower kettle and then close it, and open the circulation pump (15), the absorbent flows out of the absorption tower (1) from the absorbent outlet (7), enters the absorption tower from the absorbent inlet (6) arranged on the top of the tower and moves downward, and opens the gas material inlet (4). The gas material (1,1-difluoroethane gas containing a small amount of hydrogen fluoride) from the top of the collection tower enters the absorption tower (1) under the action of the system pressure difference, opens the steam inlet (3), and controls the absorption tower (1) tower The pressure of the kettle is 0.3MPa, the temperature of the tower kettle is controlled at 20°C, the gas material moves upwards, ...

Embodiment 2

[0025] Triethylamine was used as the liquid amine absorbent.

[0026] In the method for separating hydrogen fluoride in the production of 1,1-difluoroethane provided in Example 2 of the present invention, open the absorbent feed port (14), put a certain amount of absorbent in the tower kettle and close it, and open the circulation pump (15), the absorbent flows out of the absorption tower (1) from the absorbent outlet (7), enters the absorption tower from the absorbent inlet (6) arranged on the top of the tower and moves downward, opens the gas material inlet (4), and recovers The gas material (1,1-difluoroethane gas containing a small amount of hydrogen fluoride) from the top of the tower enters the absorption tower (1) under the action of the system pressure difference, opens the steam inlet (3), and controls the absorption tower (1) tower tank The pressure is 0.6MPa, the temperature of the tower is controlled at 80°C, the gas material moves upwards, and the reverse vapor-li...

Embodiment 3

[0028] Tri-n-butylamine is used as the liquid amine absorbent.

[0029] In the method for separating hydrogen fluoride in the production of 1,1-difluoroethane provided in Example 3 of the present invention, the absorbent feeding port (14) is opened, a certain amount of absorbent is loaded into the tower kettle and then closed, and the circulation pump is opened (15), the absorbent flows out of the absorption tower (1) from the absorbent outlet (7), enters the absorption tower from the absorbent inlet (6) arranged on the top of the tower and moves downward, opens the gas material inlet (4), and recovers The gas material (1,1-difluoroethane gas containing a small amount of hydrogen fluoride) from the top of the tower enters the absorption tower (1) under the action of the system pressure difference, opens the steam inlet (3), and controls the absorption tower (1) tower tank The pressure is 0.52MPa, the temperature of the tower is controlled at 40-45°C, the gas material moves upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com