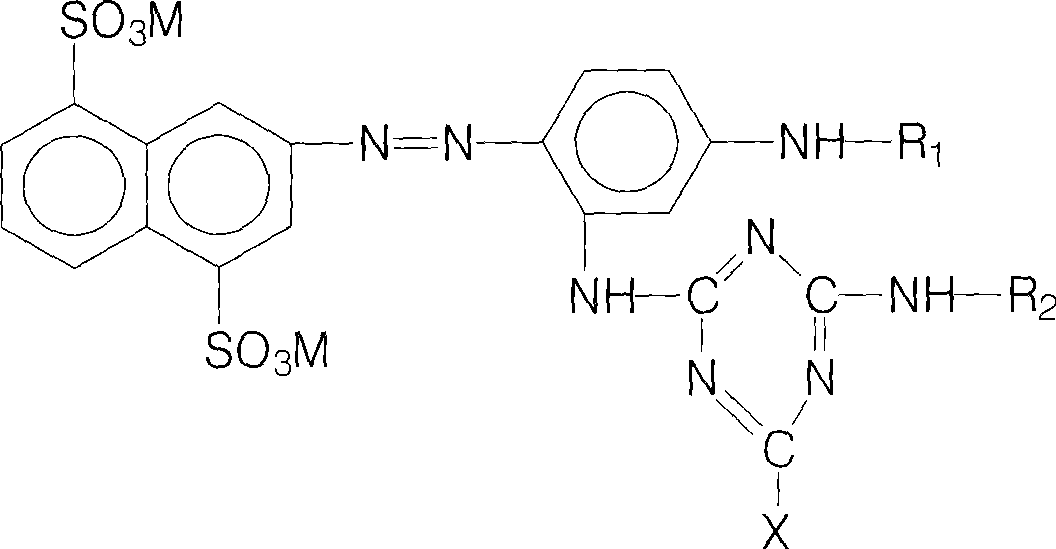

Yellow reactive dyes for wool and preparation method thereof

A technology of reactive yellow and dyes, applied in the field of dyes, can solve the problems of poor fastness index of acid dyes, a large amount of dye-containing wastewater, low coloring rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

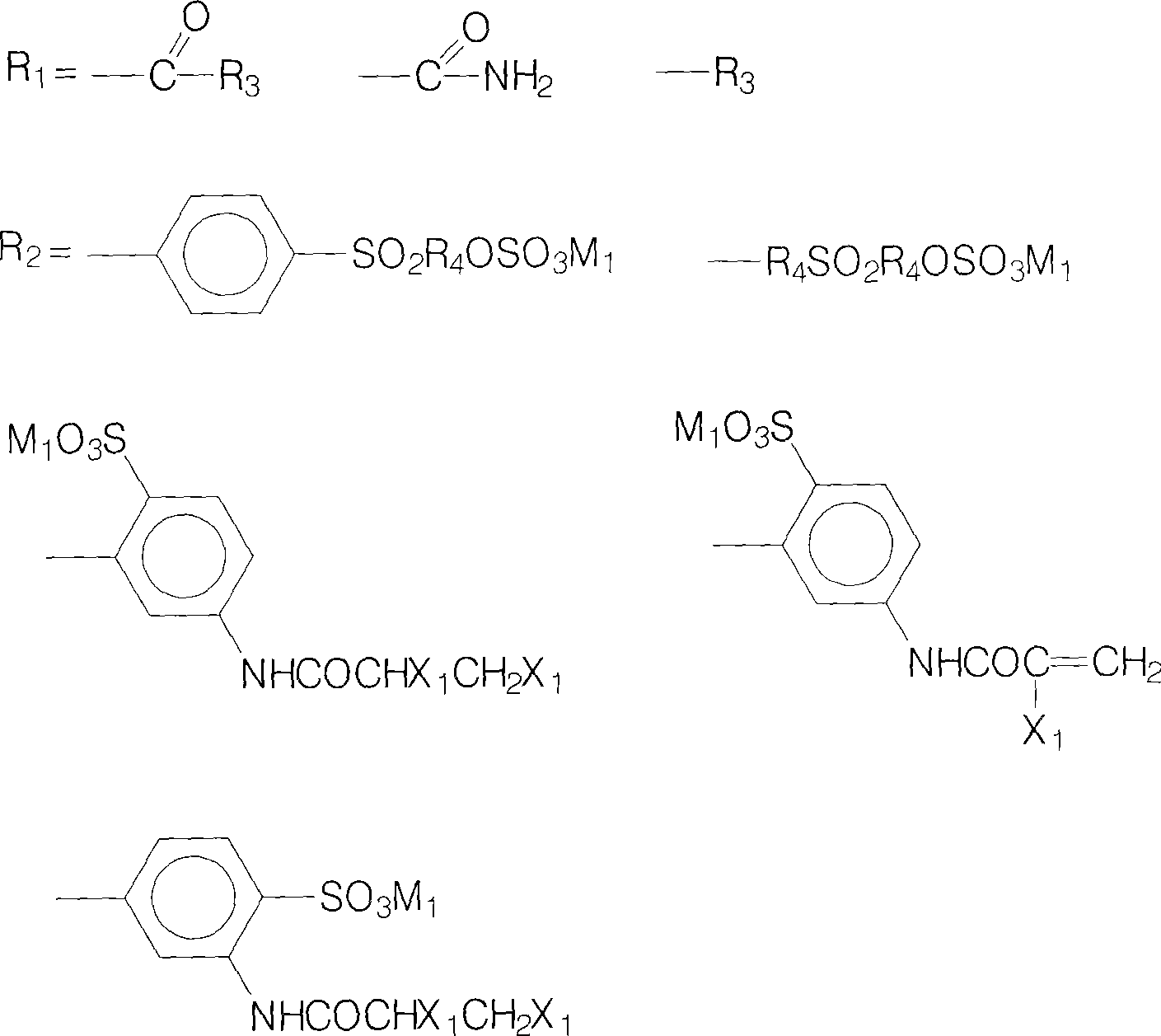

Method used

Image

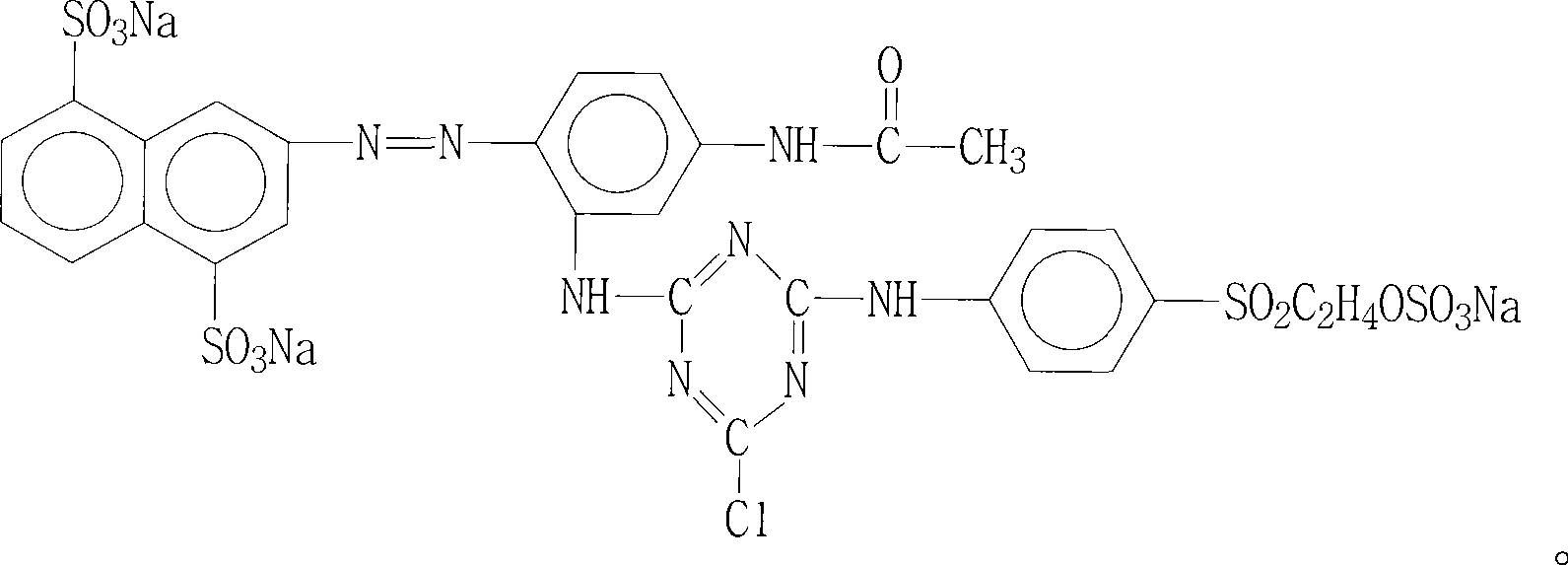

Examples

Embodiment 1

[0042] ①Diazotization of 2-naphthylamine-4,8-disulfonic acid: 433.3kg of 70% 2-naphthylamine-4,8-disulfonic acid was added to 1000kg of water and stirred evenly, then 600kg of crushed ice was added, and 146kg of 30% hydrochloric acid was added At this time, the temperature is 0°C, and then 348.5kg of 20% sodium nitrite solution is added quickly, the temperature of the addition is 3°C, and the stirring is continued for 2 hours, the end point temperature is 7°C, the sodium nitrite is slightly excessive, and 1kg of industrial sulfamic acid is used Remove excess sodium nitrite. Prepare for coupling.

[0043] ②Coupling: add m-aminoacetanilide with a content of 99% to 500kg of water, stir at room temperature for 30 minutes, then add 200kg of crushed ice to cool down to 13°C, add 2-naphthylamine-4,8-disulfonic acid in 40 minutes For diazonium salt, use 20% sodium carbonate solution to maintain PH=5.5~6.5 at the same time. After adding, the temperature is 10°C, maintain PH=6~6.5, sti...

Embodiment 2

[0048] ①Diazotization of 2-naphthylamine-4,8-disulfonic acid: add 270kg of 30% hydrochloric acid. Other same example 1.

[0049] ②③④ Same as Example 1.

[0050] ⑤ get dry product 1278kg.

Embodiment 3

[0052] ①② Same as Example 1.

[0053] 3. add 98% cyanuric chloride 186.4kg, other with example 1.

[0054] ④ Same as Example 1.

[0055] ⑤ get dry product 1220kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com