Gas liquid mixed feeding distributor and polyphenylene oxide reaction device using the same

A feed distributor and gas-liquid mixing technology, applied in the field of distributors, can solve problems affecting gas distribution effect and pressure, gas inlet blockage, etc., to increase the gas-liquid contact interface area, improve large bubbles, and reduce the amount of generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

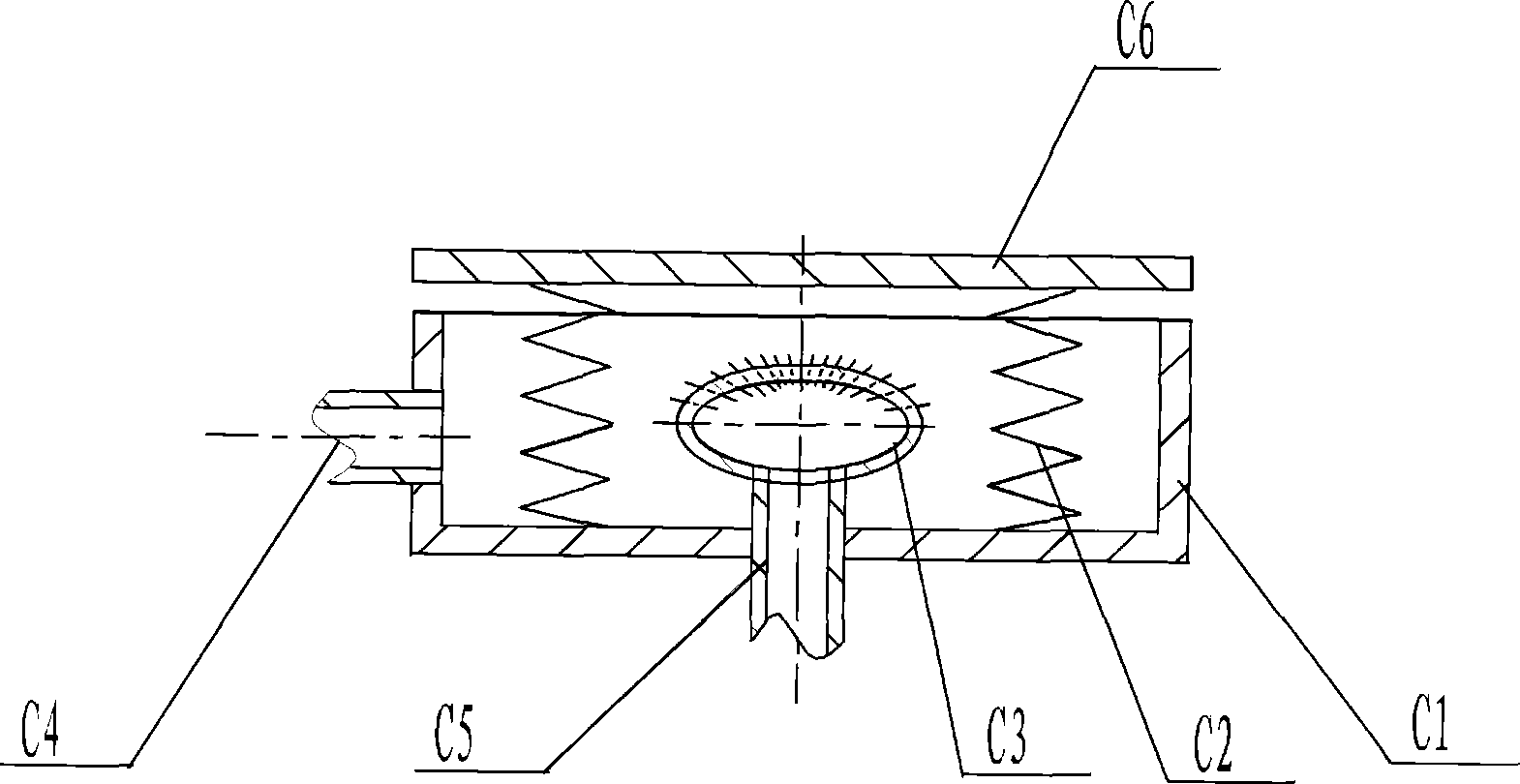

[0034] Such as figure 1 and figure 2 As shown, the gas-liquid mixed feed distributor C includes a base C1, which includes a circular bottom and a side wall. The bottom of the base C1 is connected with a gas inlet C5, and the side wall of the base C1 is connected with a liquid inlet C4 and a gas inlet. C5 is connected with a circular nozzle C3, the diameter of the hole on the nozzle is 5μm, which is used for gas distribution, and a circular cover C6 for covering the base C1 is set above the base C1, and a circular cover C6 is set between the bottom of the base C1 and the cover C6 The spring C2 is used to connect the base C1 and the cover C6.

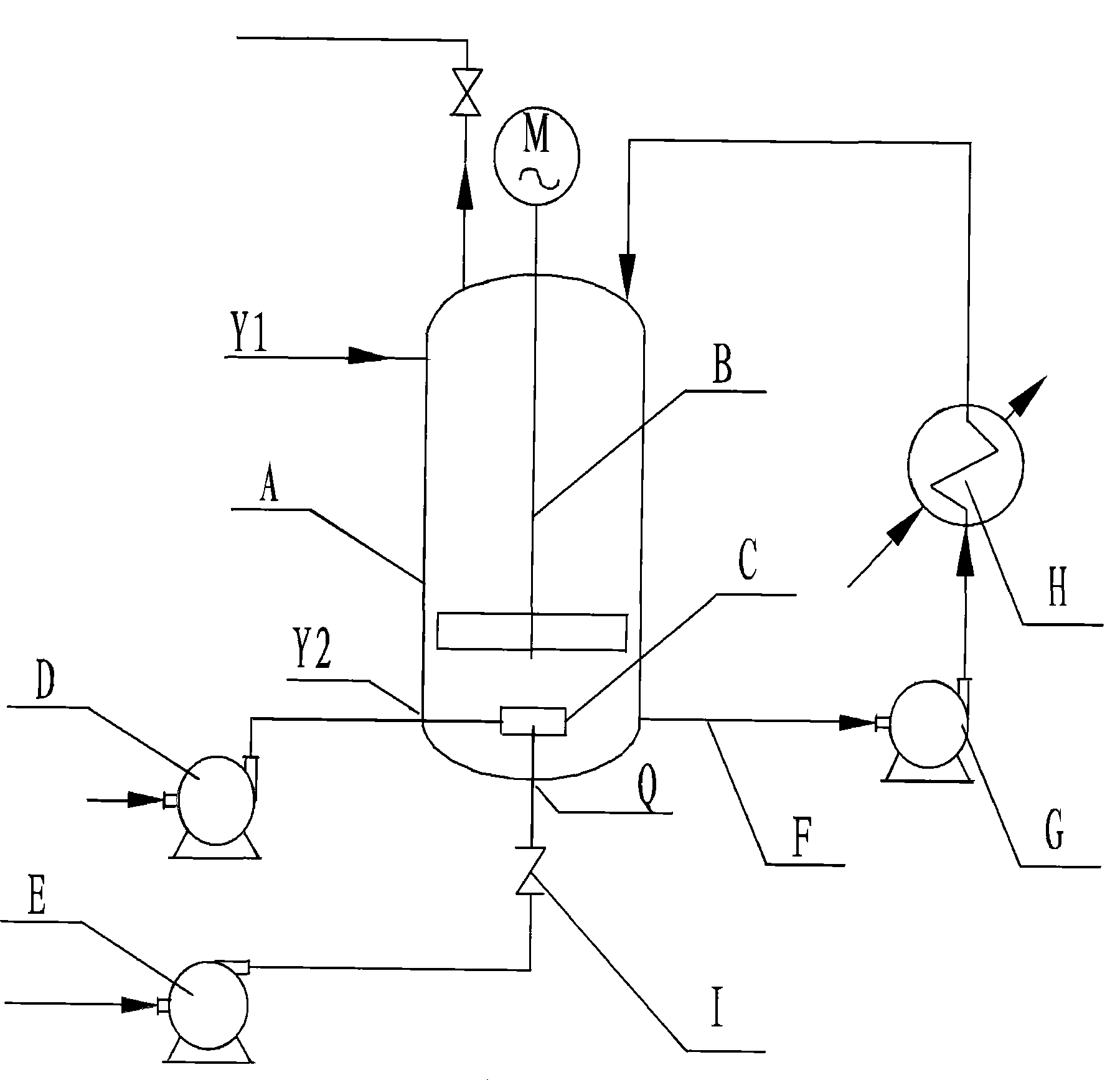

[0035] Such as figure 2 As shown, the reaction device includes a reactor A, and its side wall is provided with two liquid feed ports Y1 and Y2, which are respectively located at the upper and lower parts of the side wall, and the bottom is provided with a gas feed port Q; The mixed feed distributor C, the bottom C1 of the distributor...

Embodiment 2

[0039] The gas-liquid mixed feed distributor C in this embodiment is similar to that in Embodiment 1, wherein the bottom of the base C1 and the cover plate C6 are square, and the nozzle is also square, and the diameter of the holes on the nozzle is 50 μm.

[0040] The reaction device in this embodiment is similar to that of Example 1, wherein the agitator used in the reactor is a folded-leaf agitator, the ratio of the height to the diameter of the reactor A reaction section is 1, and the diameter of the external circulation pipeline F is the same as Reactor A has a diameter ratio of 1:2.

[0041] Using the distributor and reaction device of this embodiment, no pipeline blockage occurs, and the oxygen consumption is reduced by 10%, the by-products generated in the reaction are reduced by 10%, and high-quality polyphenylene ether products can be obtained. The obtained polyphenylene ether product is measured, using chloroform as a solvent, the measurement temperature is 25°C, and...

Embodiment 3

[0043] The gas-liquid mixed feed distributor C in this embodiment is similar to that in Embodiment 1, wherein the bottom of the base C1 and the cover plate C6 are elliptical, and the nozzle is also ellipsoid, and the diameter of the hole on the nozzle is 80 μm.

[0044] The reaction device in this example is similar to Example 1, wherein the agitator used in the reactor is a turbine agitator, the ratio of the height to the diameter of the reactor A reaction section is 10, and the pipe diameter of the external circulation pipeline F is related to the reaction The diameter ratio of device A is 1:20.

[0045] By adopting the distributor and reaction device of this embodiment, there is no pipeline blockage, and the oxygen consumption is reduced by 8%, and the by-products generated in the reaction are reduced by 15%, so that high-quality polyphenylene ether products can be obtained. The obtained polyphenylene ether product is measured, using chloroform as a solvent, the measurement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com