Synthesis technique of beta-calcium orthophosphate

A calcium phosphate technology, which is applied in the field of synthesis of β-calcium phosphate materials, can solve the problems of large grain size, time-consuming, easy to stick to dirt, etc., and achieve the effect of stable product performance, strong repeatability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

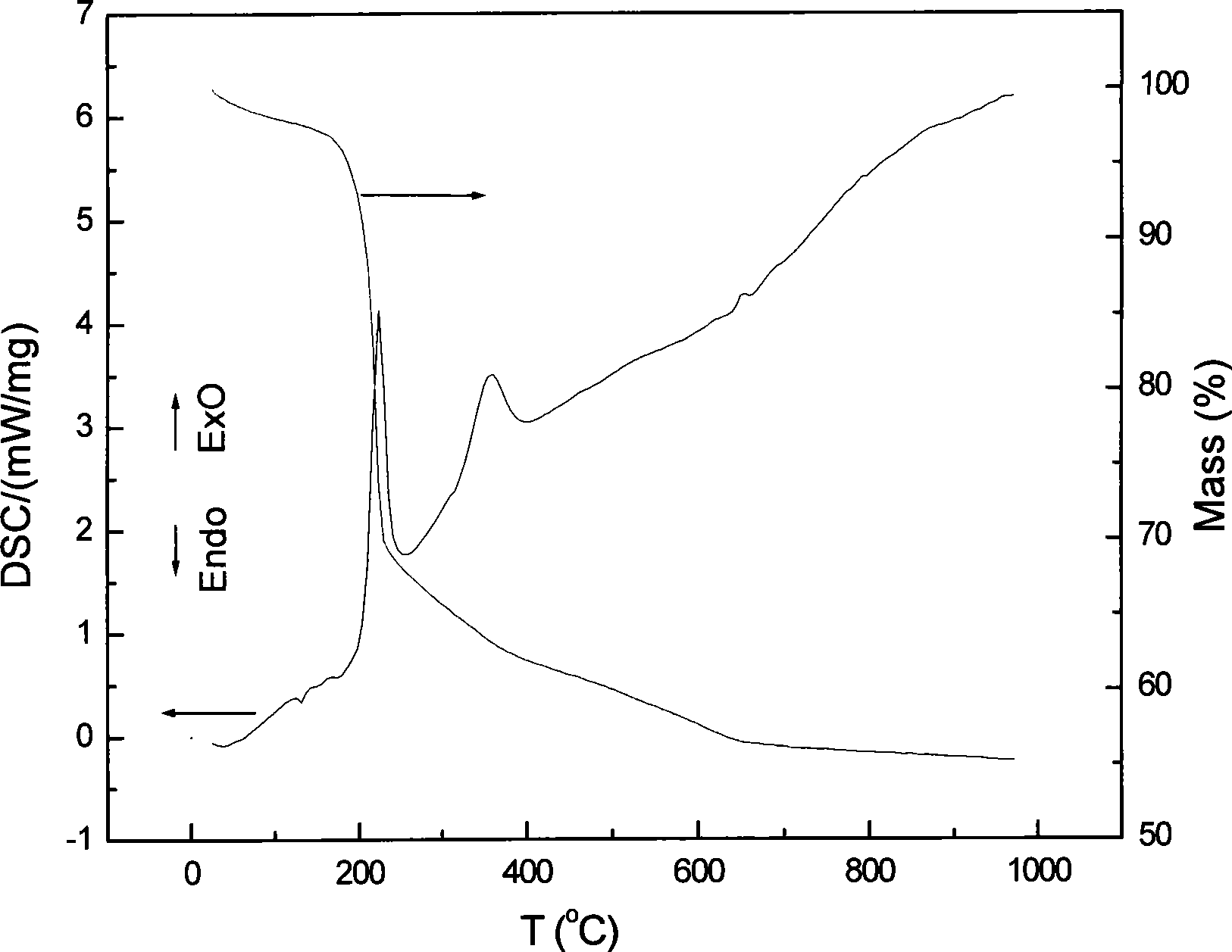

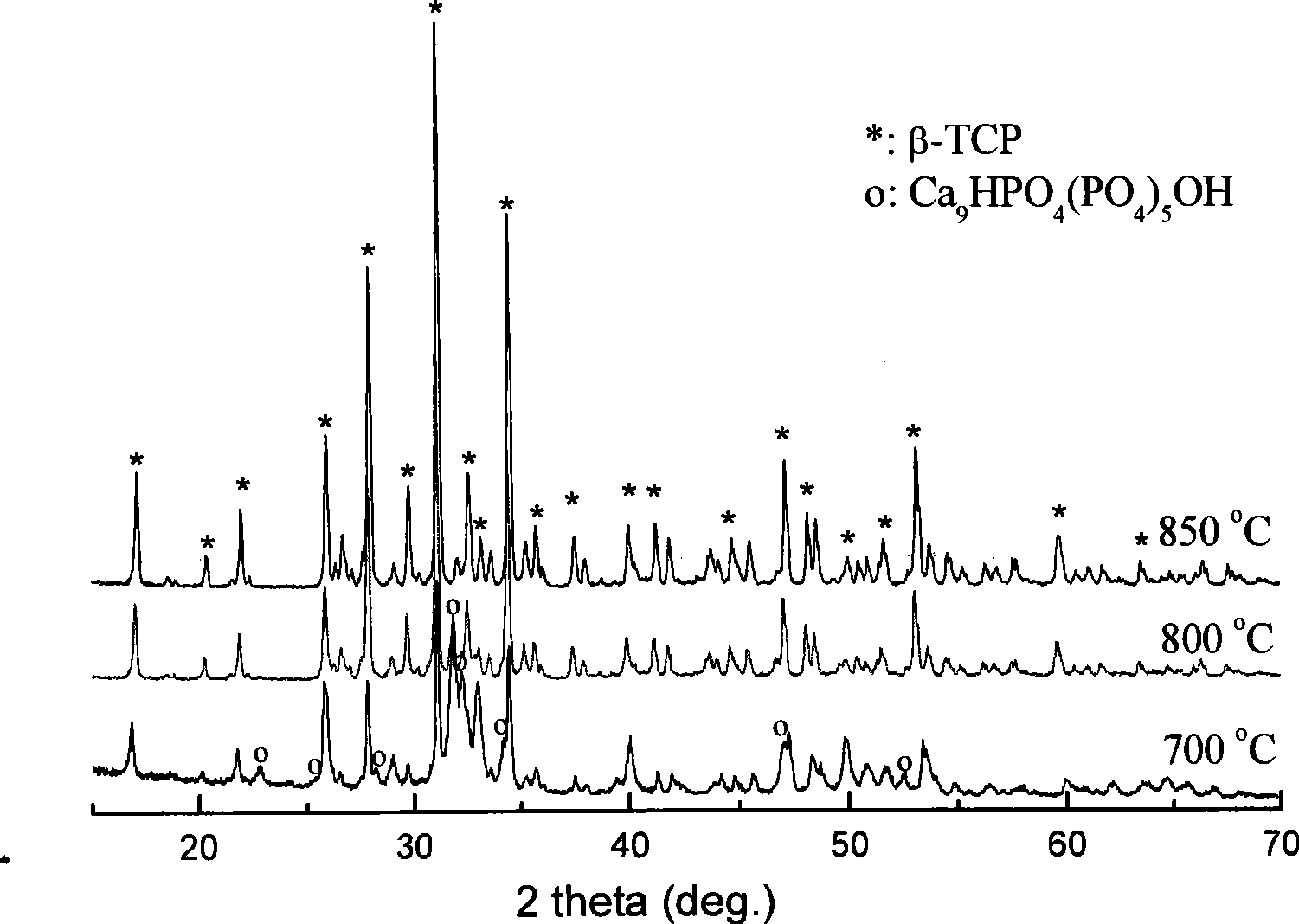

Embodiment 1

[0026] The formula of each component is shown in Table 1. Weigh an appropriate amount of PS microspheres, add concentrated sulfuric acid, stir on a magnetic stirrer for 5 hours, and disperse by ultrasonic for half an hour, repeating 2-3 times. After being centrifuged and washed with absolute ethanol, it was dried and set aside. Weigh calcium nitrate and diammonium hydrogen phosphate to make a saturated solution, slowly drop diammonium hydrogen phosphate into the calcium nitrate solution with a ratio of calcium to phosphorus of 1.5:1, and add vulcanized PS microspheres and surfactant CTAB at the same time Adjust the pH value of the reaction with ammonia water at about 9, stir on a magnetic stirrer, age after the reaction is sufficient, centrifuge and wash repeatedly with absolute ethanol, dry in a drying oven at 70°C, and calcined to 700°C, 800°C, 850°C Keep warm for 3 hours respectively.

[0027] Table 1: Formulation of each component

[0028]

Embodiment 2

[0030] Weigh an appropriate amount of PS microspheres, add concentrated sulfuric acid, stir on a magnetic stirrer for 6 hours, disperse by ultrasonic for half an hour, repeat 2-3 times. After being centrifuged and washed with absolute ethanol, it was dried and set aside. Weigh calcium nitrate and diamine hydrogen phosphate to form a saturated solution, the molar ratio of calcium to phosphorus is 1.4:1, add vulcanized PS microspheres and surfactant CTAB ammonia water at the same time to adjust the pH value of the reaction to about 8.5, magnetically stir Stir on the container, age after the reaction is complete, centrifuge and wash repeatedly with absolute ethanol, dry in an oven at 70°C, and calcined to 700°C, 800°C, and 850°C for 3 hours respectively.

Embodiment 3

[0032] Weigh an appropriate amount of PS microspheres, add concentrated sulfuric acid, stir on a magnetic stirrer for 5 hours, disperse by ultrasonic for half an hour, repeat 2-3 times. After being centrifuged and washed with absolute ethanol, it was dried and set aside. Weigh calcium nitrate and diammonium hydrogen phosphate to form a saturated solution. The molar ratio of calcium to phosphorus is 1.6:1. At the same time, add vulcanized PS microspheres and surfactant CTAB ammonia water to adjust the pH value of the reaction to about 8. Magnetic stirring Stir on the container, age after the reaction is complete, centrifuge and wash repeatedly with absolute ethanol, dry in an oven at 70°C, and calcined to 700°C, 800°C, and 900°C for 3 hours respectively.

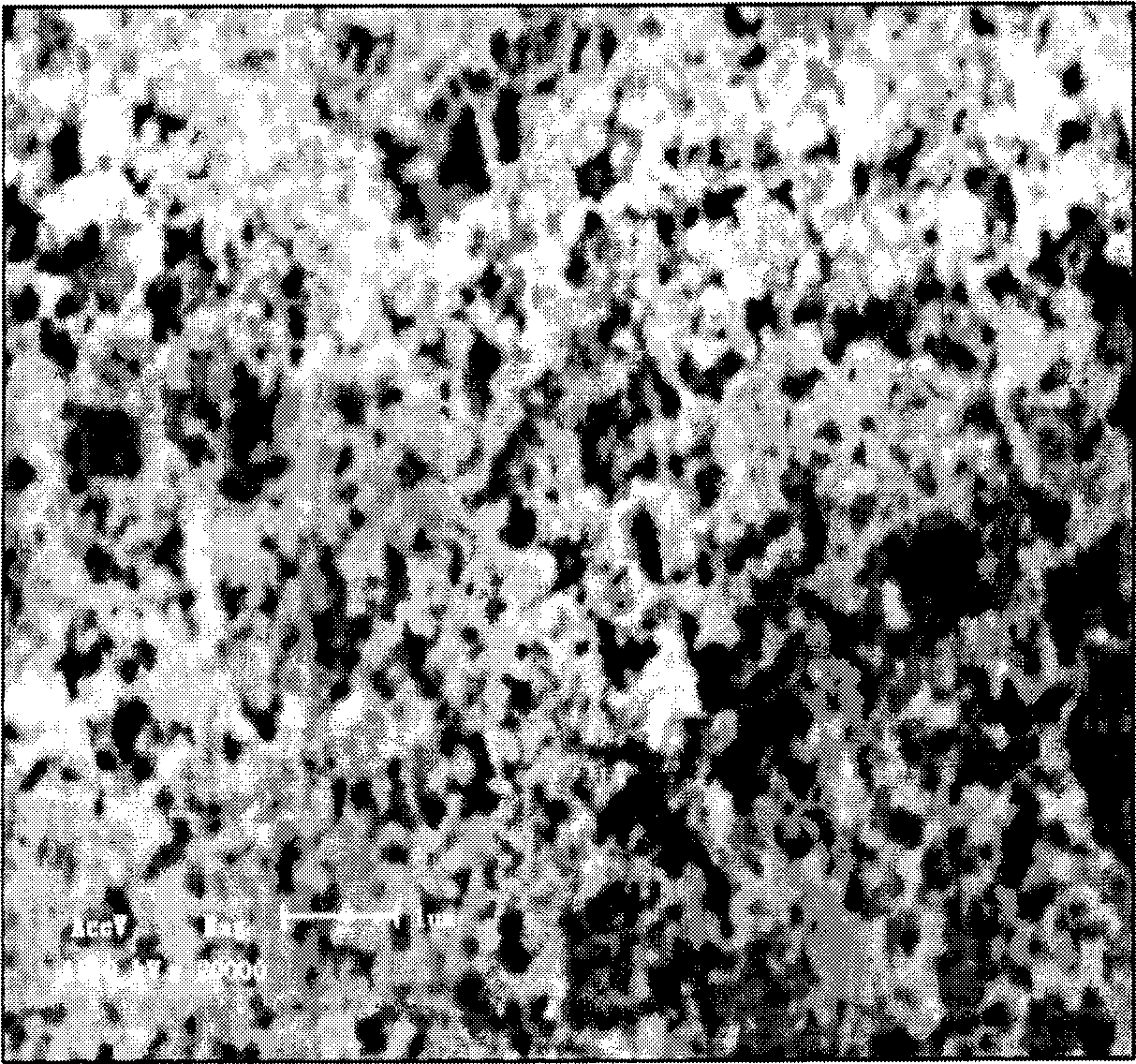

[0033] The invention synthesizes β-calcium phosphate with pore size and high purity by adding PS microspheres in the chemical reaction process. The PS microspheres are used as templates, and have the characteristics of simple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com