Sulfitation intensity on-line automatic detection apparatus

An automatic detection device and strength technology, applied in the direction of chemical analysis by titration method, can solve the problems of high labor intensity, low degree of automation, long measurement and control cycle, etc., to improve the economic benefits of enterprises, convenient maintenance and safe use reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

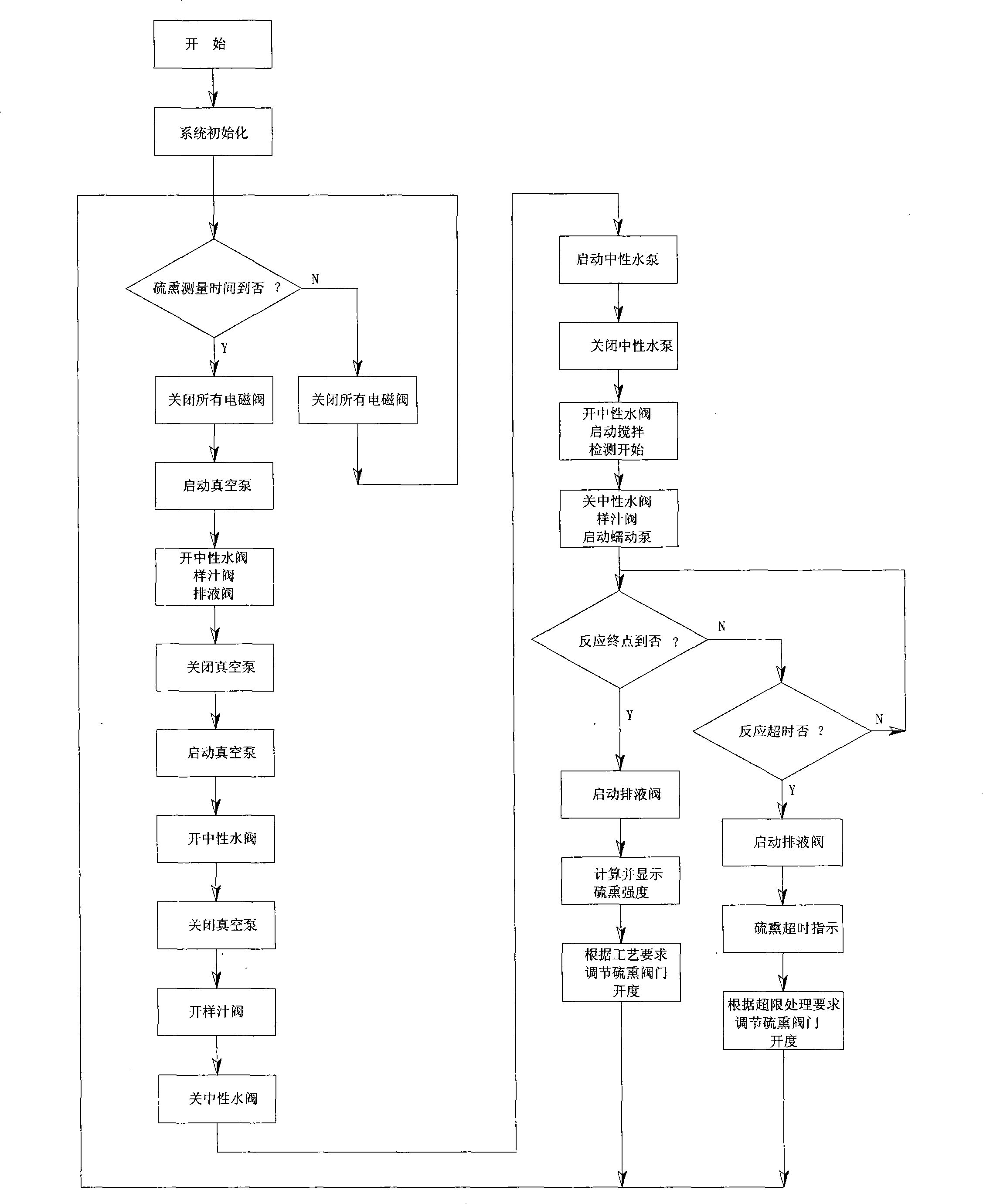

Method used

Image

Examples

Embodiment Construction

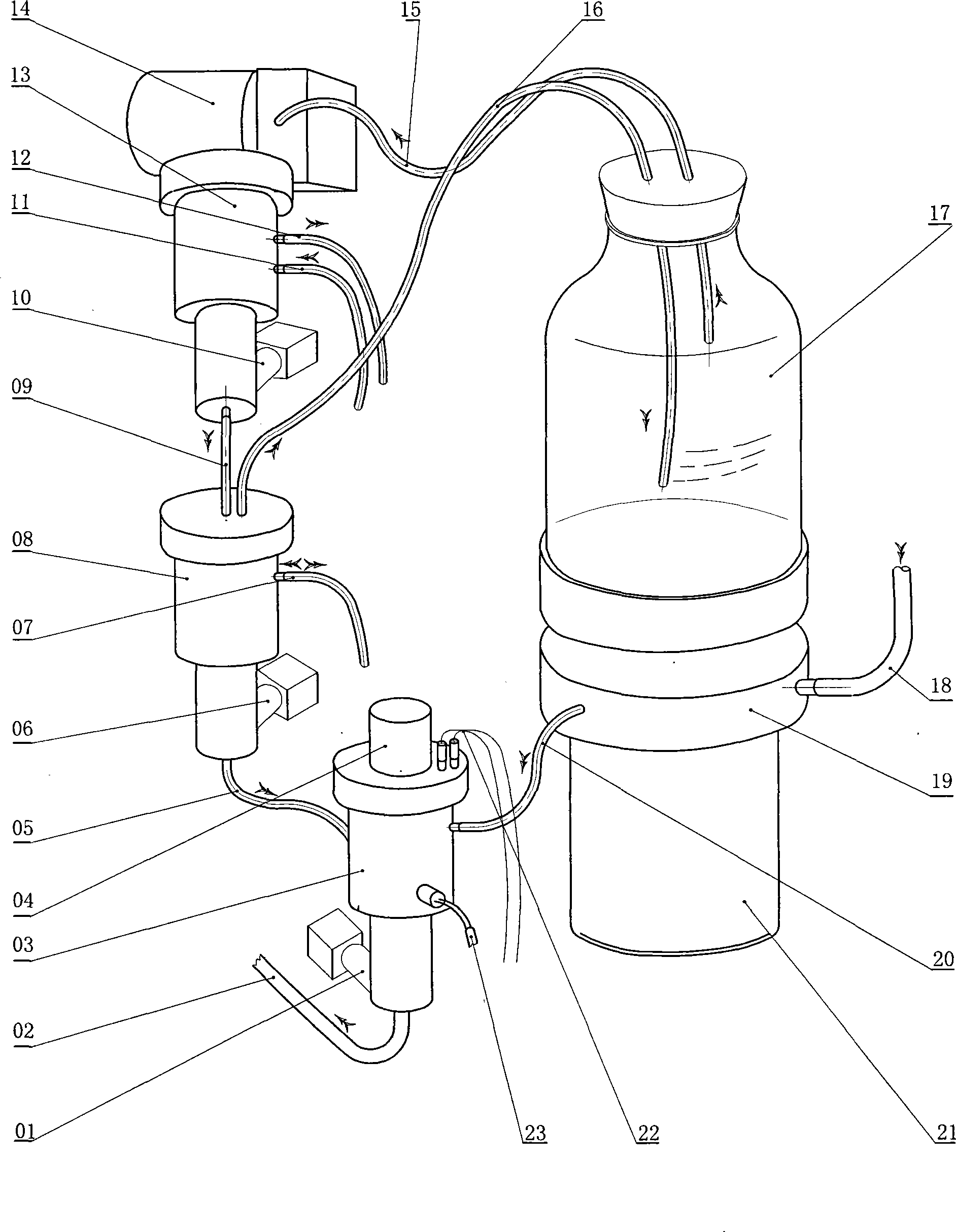

[0024] Among the figure, first start the vacuum pump (14), the vacuum pump (14) evacuates the air in the vacuum bottle (17) through the vacuum evacuation tube (15), and the vacuum bottle (17) evacuates the sugarcane source cup through the cane juice cup evacuation tube (16). The air in (08) is evacuated, at this time, the sugarcane juice is sucked into the cup through the cane juice inlet and return pipe (07), and after reaching the designed flow rate, the excess part is also discharged from the sugarcane juice inlet and return pipe (07). Keep the cane juice in the cup to maintain the specified amount. At the same time, in the neutral water measuring cup (13), the neutral water enters from the neutral water inlet pipe (11), and the excess part is discharged from the neutral water return pipe (12), so that the neutral water measuring cup (13) maintains the prescribed amount of liquid. Now, open the sugarcane juice cup outlet valve (06) and the neutral water metering cup outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com