Semiconductor wafer metal substrate web corrosion prevention liquid and its use method

A metal substrate, corrosion protection technology, applied in the field of cleaning fluid, can solve the problem of small operating window, achieve low corrosion rate, good application prospects, and improve the effect of operating window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~22

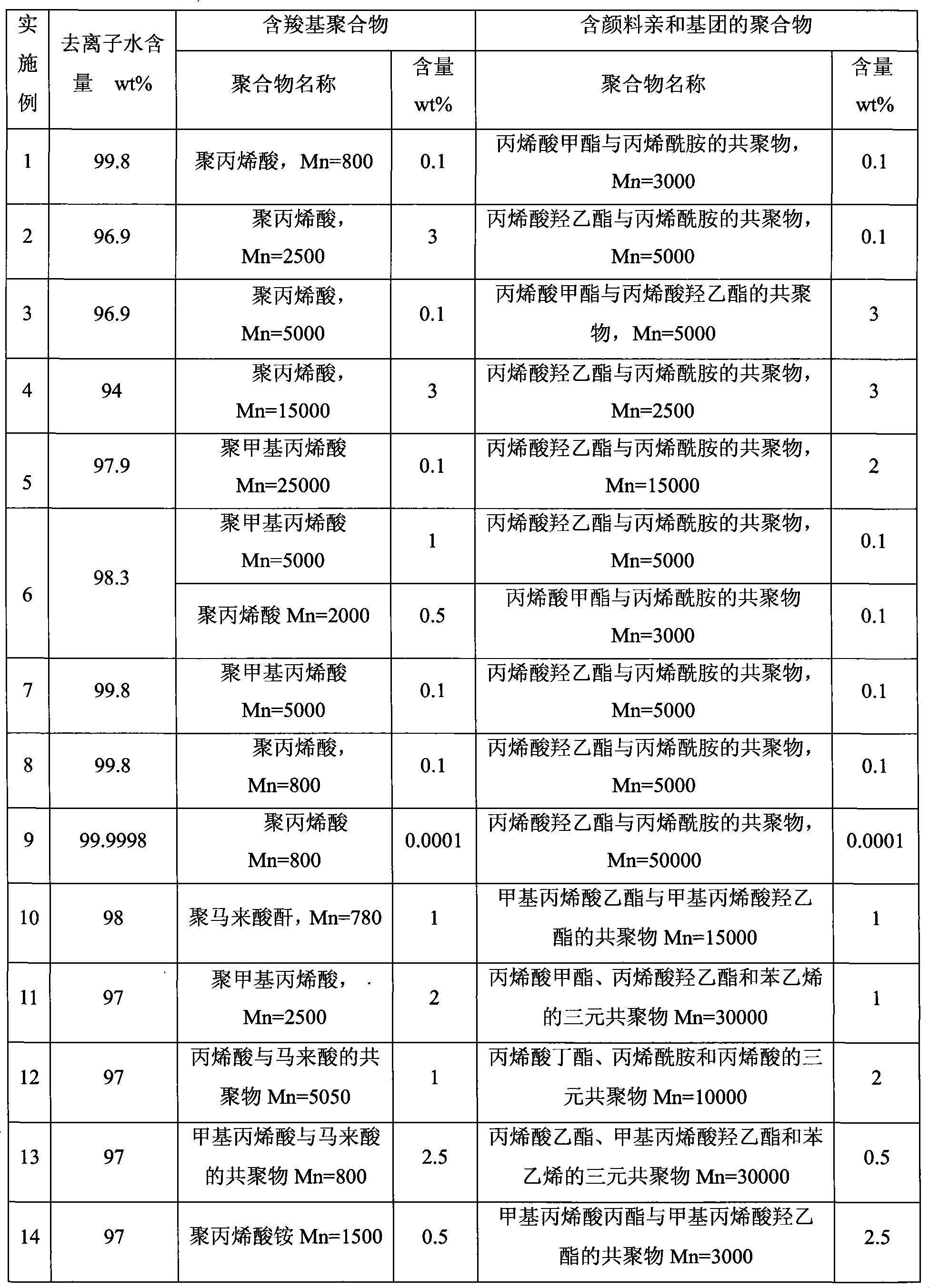

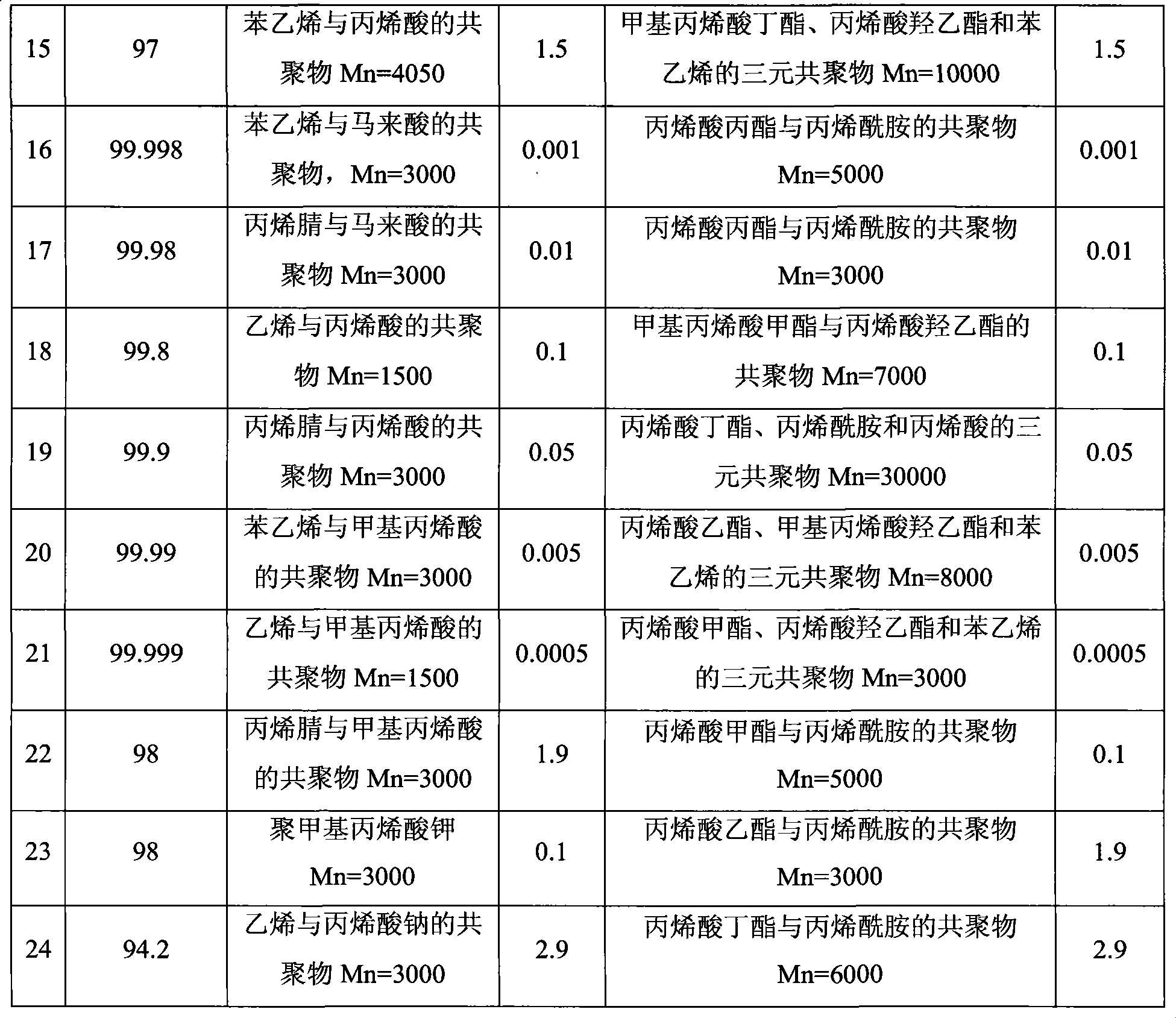

[0025] Table 1 shows the formulas of Examples 1-22 of the semiconductor wafer metal substrate corrosion protection liquid of the present invention. According to the components listed in Table 1 and their contents, simply mix them uniformly to obtain each semiconductor wafer metal substrate Material corrosion protection fluid.

[0026] Table 1 Semiconductor wafer metal substrate corrosion protection solution 1-22 of the present invention

[0027]

[0028]

Embodiment 1

[0030] The method of using the corrosion protection liquid for the metal substrate of the semiconductor wafer, the specific steps:

[0031] 1. Use the hydroxylamine cleaning solution (F1) in Table 2 to clean the plasma-etched wafer at 65° C. for 20 minutes.

[0032] 2. Use the metal corrosion protection solution 8 in Table 1 to clean the wafer with rotating spray for 10 minutes.

[0033] 3. Dry afterwards.

Embodiment 2

[0035] The method of using the corrosion protection liquid for the metal substrate of the semiconductor wafer, the specific steps:

[0036] 1. Use the hydroxylamine-based cleaning solution (F1) in Table 2 to clean the plasma-etched wafer at 65° C. for 15 minutes.

[0037] 2. Use the metal corrosion protection solution 8 in Table 1 to perform rotary spray cleaning on the wafer for 5 minutes.

[0038] 3. Clean the wafer with deionized water for 2 minutes in a spin spray.

[0039] 4. Dry afterwards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com