Ultraviolet and ozone combined disinfection method for nutrient solution

A disinfection method and ultraviolet disinfection technology, which are applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. Efficiency, improve sterilization effect, reduce power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

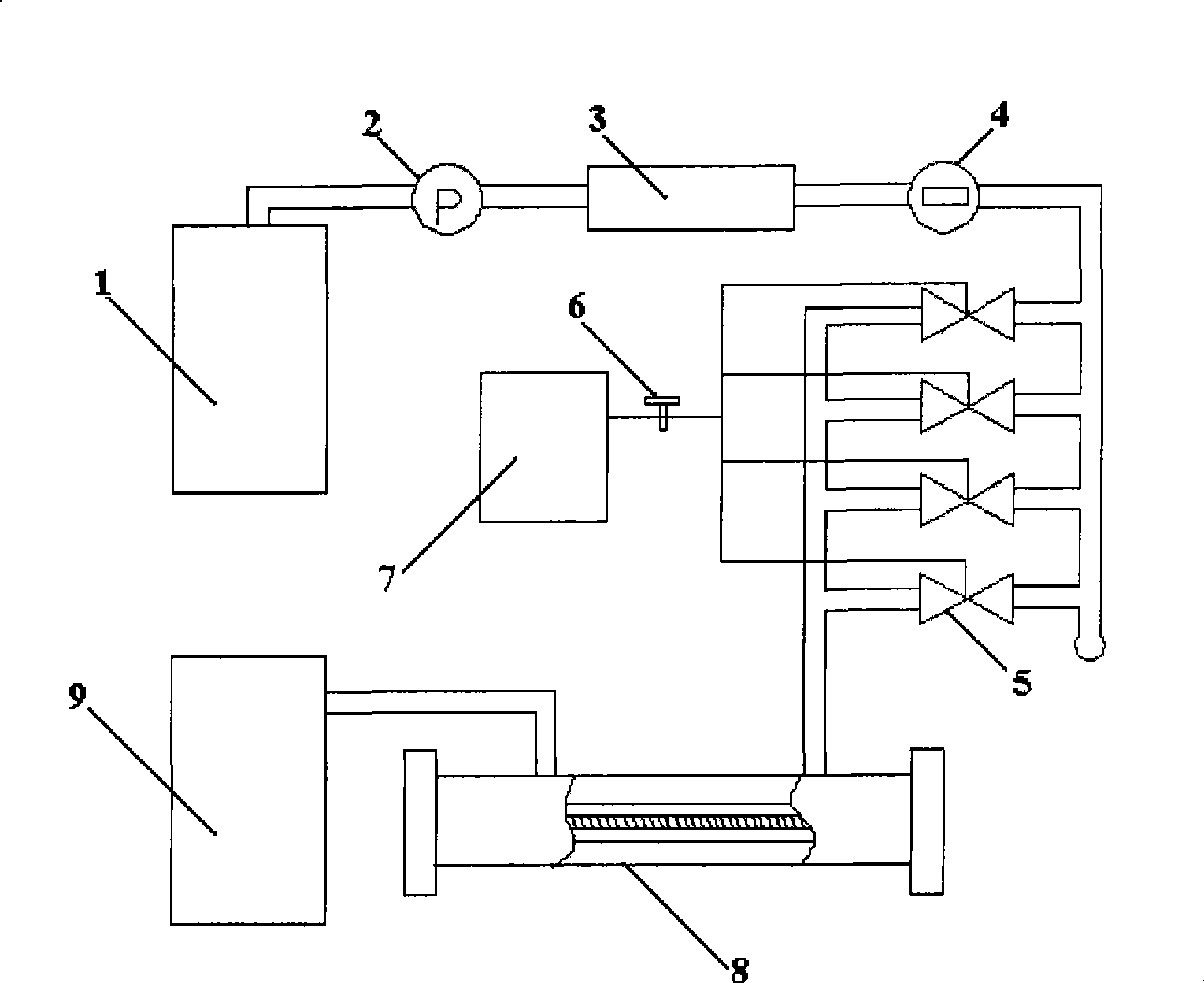

[0039] The present invention provides an ultraviolet-ozone combined disinfection method for nutrient solution, and the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0040] figure 1 It is a schematic flow chart of the ultraviolet-ozone combined nutrient solution disinfection method. The liquid to be disinfected in the nutrient solution pool 1 is sucked into the pipeline by the stainless steel corrosion-resistant self-priming pump 2, and the flow rate is 20m 3 / h; the nutrient solution enters the screen filter 3, and passes through a 120-mesh screen to filter out the ozone-depleting organic matter in the nutrient solution, reducing the ineffective loss of ozone, and reducing the opaque impurity content in the nutrient solution, improving the nutrient solution. The transmittance improves the ultraviolet sterilization effect; the filtered nutrient solution flows into the 4 venturi-type jets 5 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com