Decolorization method for recycling vinyl benzene with pyrolysis gasoline

A technology for pyrolysis of gasoline and styrene, applied in the fields of organic chemistry, distillation purification/separation, etc., which can solve the problems of high equipment requirements, complex solid waste and process, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

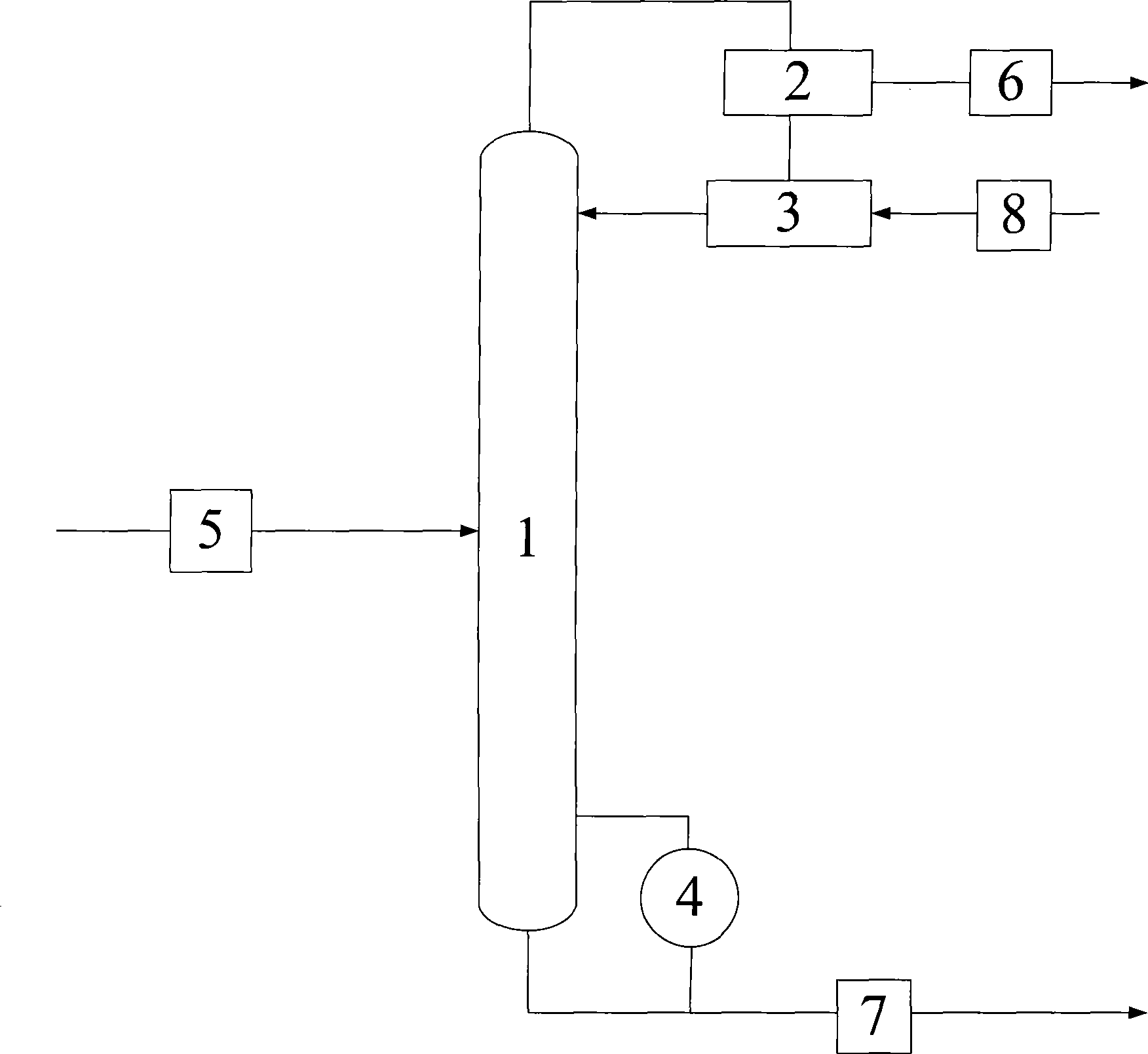

Image

Examples

Embodiment 1

[0014] Crude styrene enters the refined styrene column with 10 theoretical plates at 10 g / min, the feeding position is the fifth theoretical plate, the reflux ratio is 5, the operating pressure is 12KPa, and the temperature at the top of the tower is controlled at 79-79.5°C. After the pure styrene vapor at the top of the tower is condensed by the condenser, the flow rate of the extracted pure styrene is 8 g / min, the chromaticity of pure styrene is 10 in terms of platinum cobalt chromaticity unit, and the remaining styrene flows in at 40 g / min In the reflux tank, the decolorizing agent maleic acid enters the reflux tank at 0.05 g / min. After the two are mixed and dissolved, they enter the top of the purified styrene tower, and the heavy components obtained in the tower reactor are extracted at 2 g / min.

Embodiment 2

[0016] Crude styrene enters the purified styrene tower with 50 theoretical plates at 10 g / min, the feeding position is the 25th theoretical plate, the operating pressure is 10KPa, the reflux ratio is 1, and the temperature at the top of the tower is controlled at 75-75.5°C. After the pure styrene vapor at the top of the tower is condensed by the condenser, the flow rate of the extracted pure styrene is 8 g / min, the chromaticity of pure styrene is 5 in terms of platinum cobalt chromaticity unit, and the remaining styrene flows in at 8 g / min The reflux tank, the decolorizing agent oxalic acid enters the reflux tank at 0.5 g / min, the two are mixed and dissolved and enter the top of the purified styrene tower, and the heavy components of the tower reactor are extracted at 2 g / min.

Embodiment 3

[0018] Crude styrene enters the purified styrene tower with 30 theoretical plates at 10 g / min, the 15th theoretical plate is fed into the position, the operating pressure is 8KPa, the reflux ratio is 2, and the temperature at the top of the tower is controlled at 69-69.5°C. After the top pure styrene vapor is condensed by the condenser, the flow rate of pure styrene is 8 g / min, the chromaticity of pure styrene is 5 in platinum cobalt chromaticity unit, and the remaining styrene flows into reflux at 16 g / min tank, the decolorizing agent maleic anhydride enters the reflux tank at 0.05 g / min, the two are mixed and dissolved and enter the top of the refined styrene tower, and the heavy components in the tower reactor are extracted at 2 g / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com