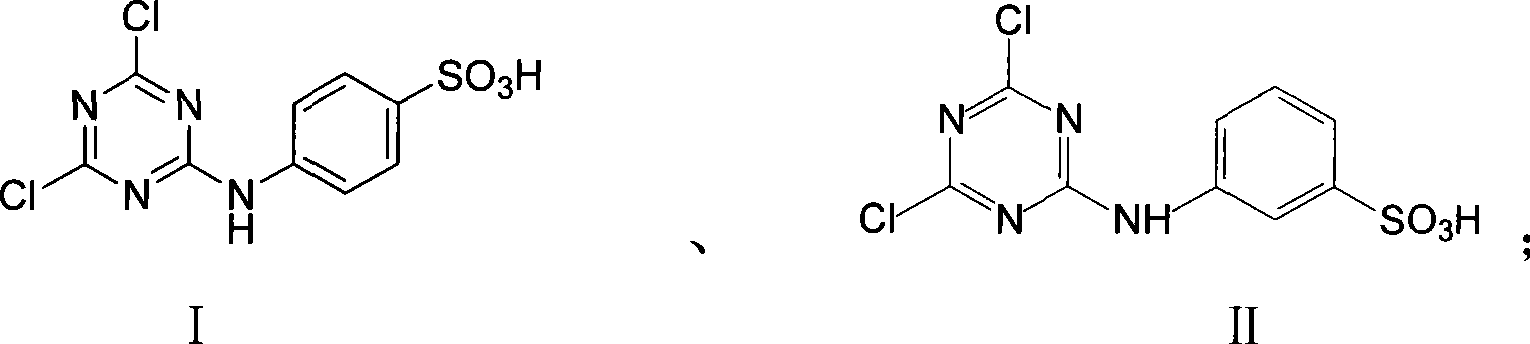

Process for producing triazine toluylene liquid fluorescent whitening agents

A technology of triazine stilbene and fluorescent whitening agent, applied in the directions of styryl dyes, chemical instruments and methods, luminescent/fluorescent substance addition, etc., can solve the problems of affecting production costs, low product yield, complex methods and the like , to achieve the effect of yield and quality improvement, good storage stability, and good whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Chemical Name Feeding quantity (g) Cyanuric chloride 25 m / p-aminobenzenesulfonic acid (molar ratio 1.5 / 8.5) 3.5 / 20 DSD acid 23.4 Diethanolamine 14.5 30% liquid alkali 90

Embodiment 2

[0030] Chemical Name Feeding quantity (g) Cyanuric chloride 25 m / p-aminobenzenesulfonic acid (molar ratio 2 / 8) 4.7 / 18.8 DSD acid 23.4 Diethanolamine 14.5 30% liquid alkali 90

Embodiment 3

[0032] Chemical Name Feeding quantity (g) Cyanuric chloride 25 m / p-aminobenzenesulfonic acid (molar ratio 3 / 7) 7.1 / 16.4 DSD acid 23.4 Diethanolamine 14.5 30% liquid alkali 90

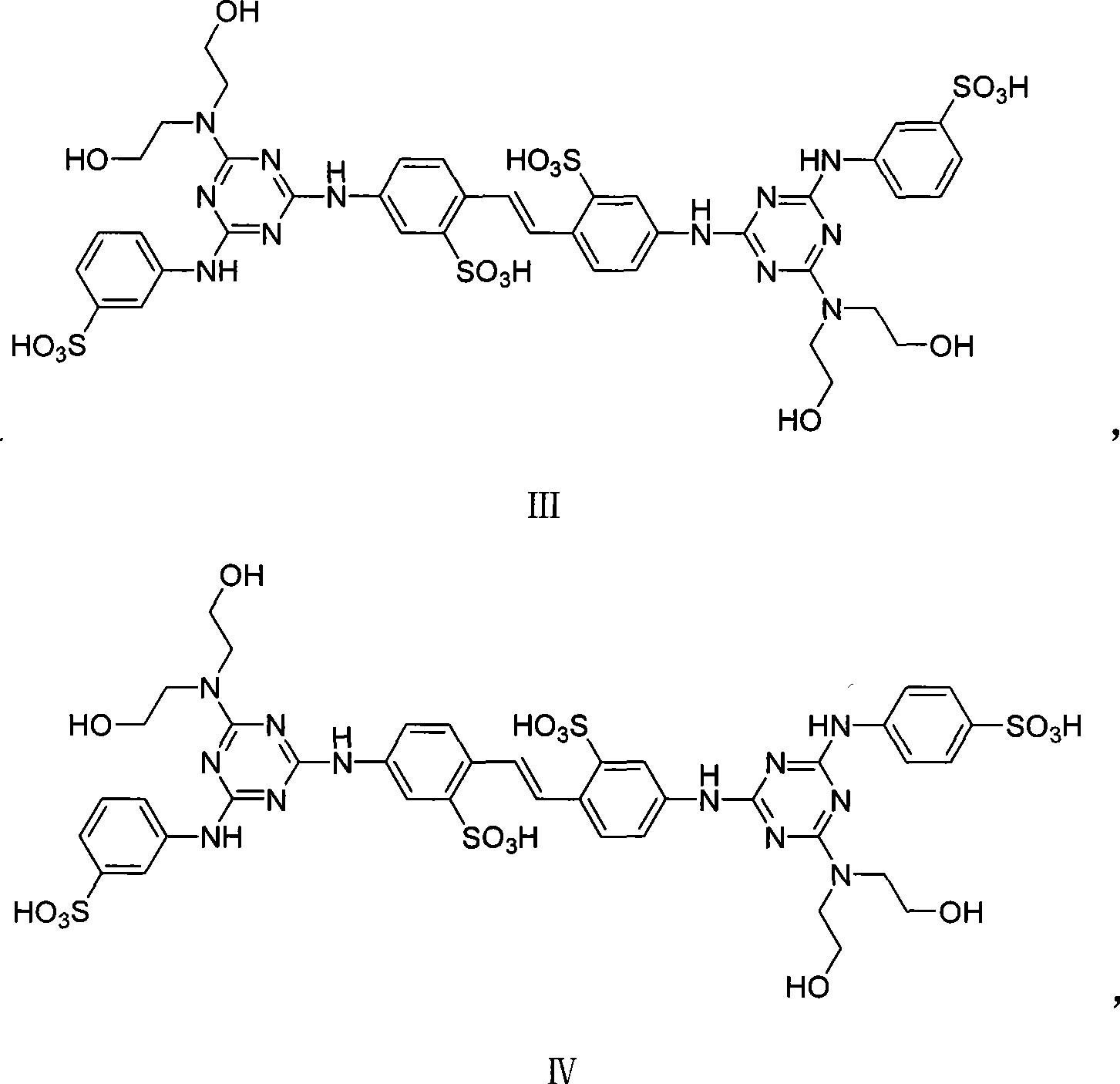

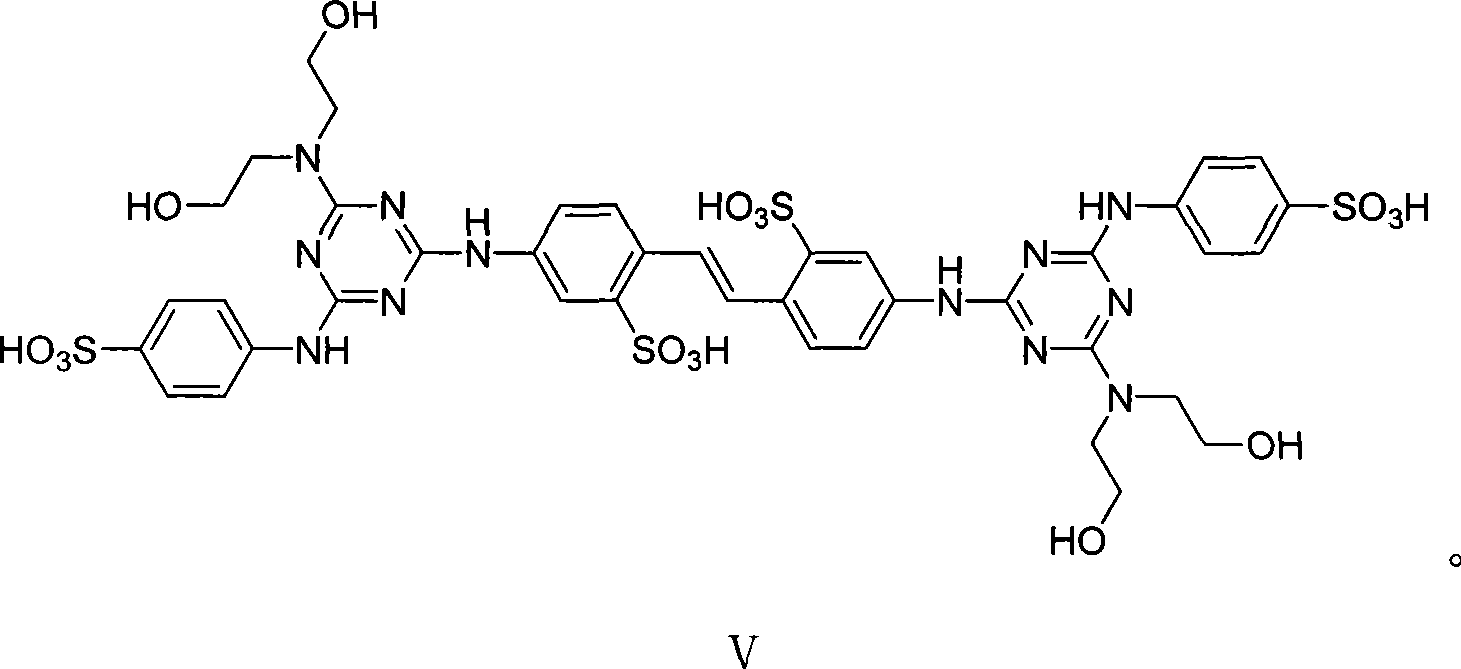

[0033] The synthetic steps of three-component triazine stilbene liquid fluorescent whitening agent are as follows:

[0034] (1) One-step reaction: add 350ml of water to a three-necked flask, and use an ice bath to cool at a temperature of 0-3°C, then add hydrochloric acid to control the pH value at about 1.5, and then add cyanuric chloride (hereinafter referred to as CNC) , 30% liquid caustic soda and m / p-aminobenzenesulfonic acid, make it react with stirring, control pH value 2.0-3.0, temperature 0-4 ℃, use amino indicator to judge the reaction end point.

[0035] (2) Two-step reaction: add DSD acid with a molar ratio of 0.48 to CNC, control the pH value to 5.0-7.0, the temperature is 30-40°C, and use the amino indicator to judge the end point.

[0036] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com