High-strength steel tension rod and thermal treatment method thereof

A heat treatment method and high-strength steel technology, applied in the field of metallurgy, can solve the problems of serious decarburization on the surface of steel tie rods, large fluctuations in performance and quality, and coarse microstructure and grains, and achieve fine microstructure and product flatness. Good, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation of the present invention will be described below in conjunction with the examples.

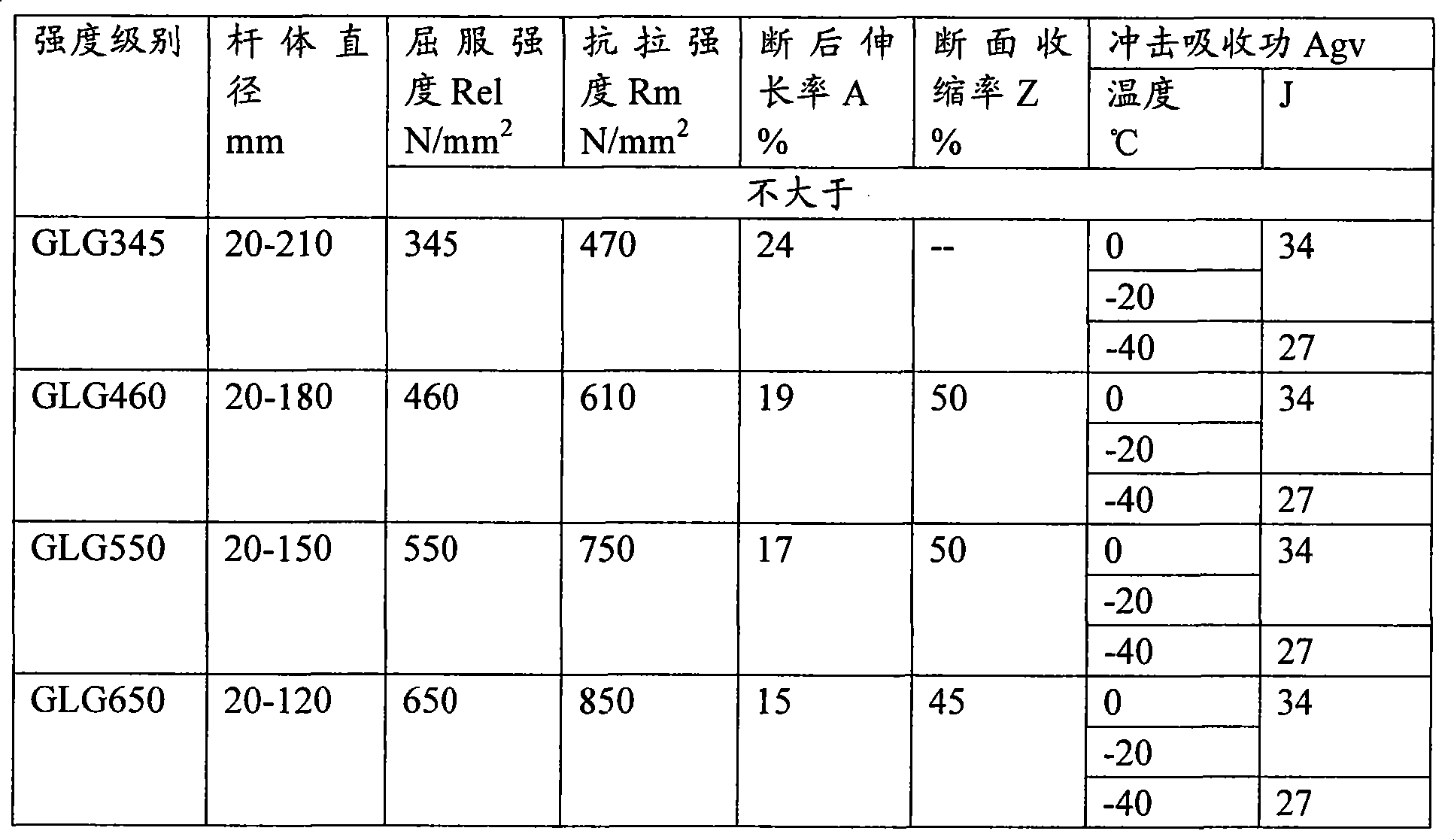

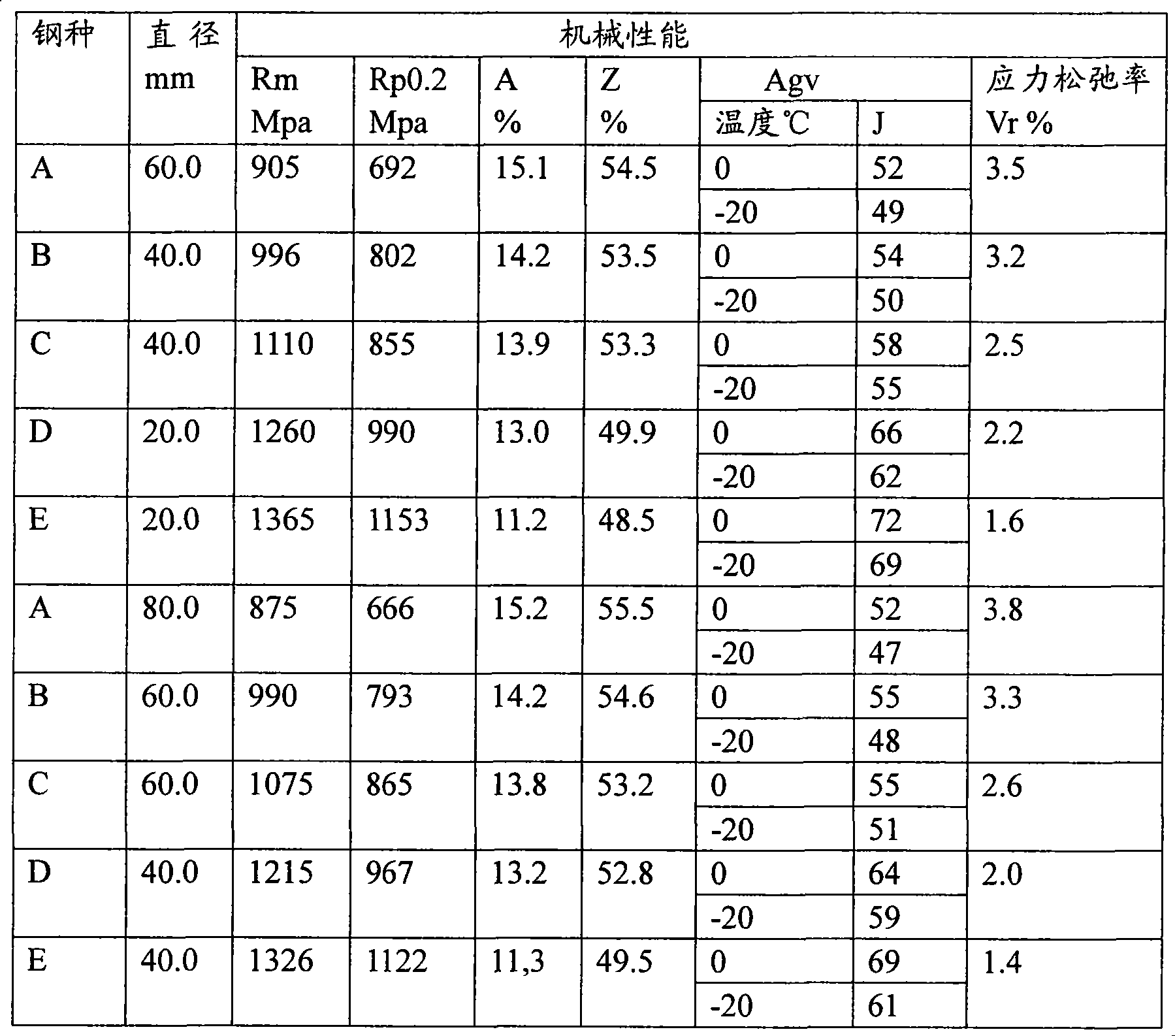

[0030] The ingredients involved in each example are shown in Table 1 below.

[0031] The raw materials used in the present invention are carbon structural steel or alloy structural steel bars, and the feeding, roller conveying, loosening of front traction rollers, quenching induction heating, quenching cooling, and returning to the steel tie rod body are continuously completed on the induction heat treatment production line. The whole production process of fire induction heating, tempering cooling, rear pull-in roller feeding, roller conveying, unloading, collecting and packaging. Quenching heating temperature: 850-1050°C, then cooling to below 250°C, tempering heating temperature: 400-700°C.

[0032] Among them, in the induction heat treatment production line, an intermediate frequency inductor with equal diameter and multi-turn coils is used to heat the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com