Permanent magnet direct-driving aerogenerator

A wind turbine, permanent magnet direct drive technology, applied in wind turbines, wind turbine combinations, wind power generation, etc., can solve the problem of unsatisfactory failure rate and service life, high production cost of rectifier inverter, complex gearbox structure, etc. problem, to achieve the effect of low noise, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

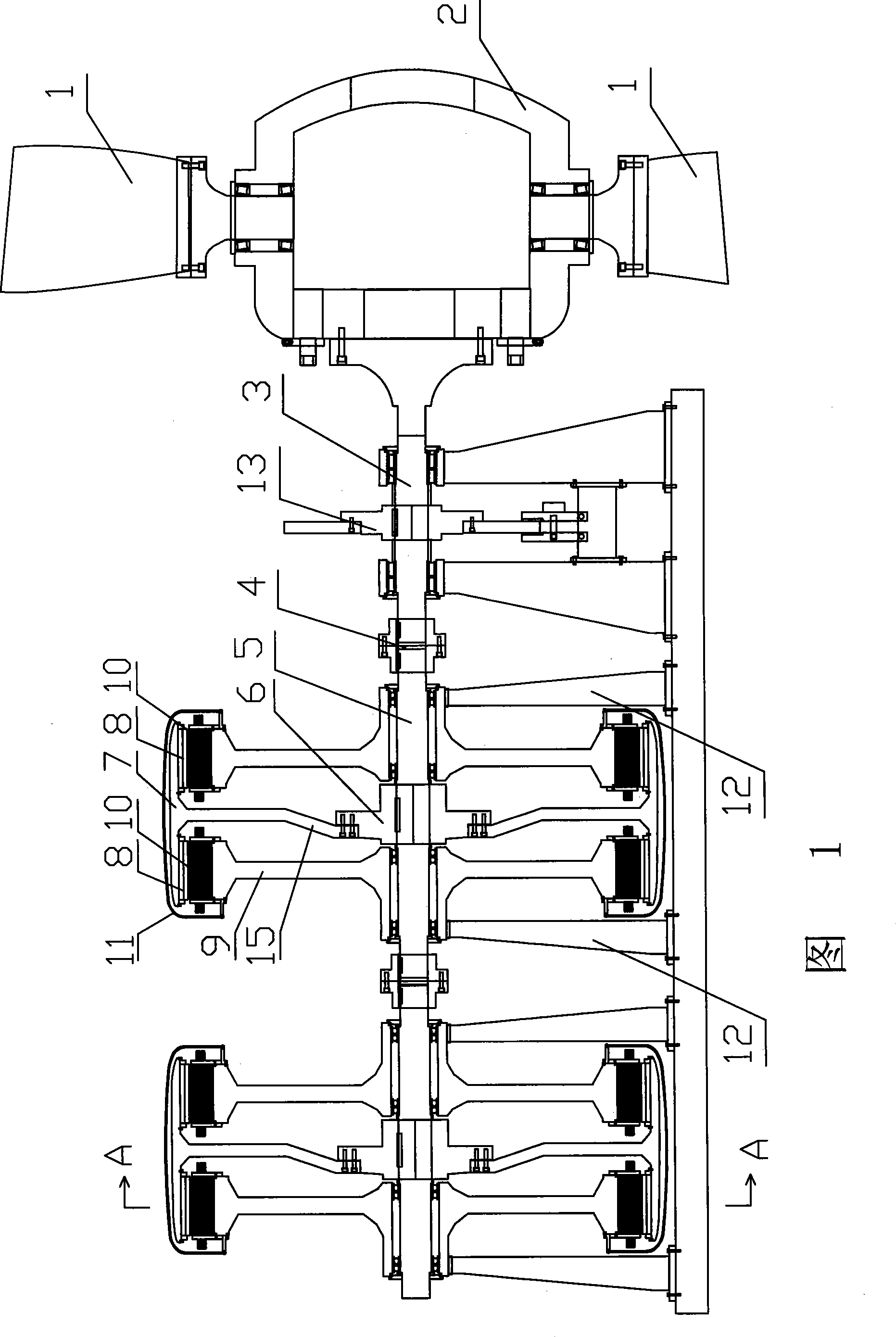

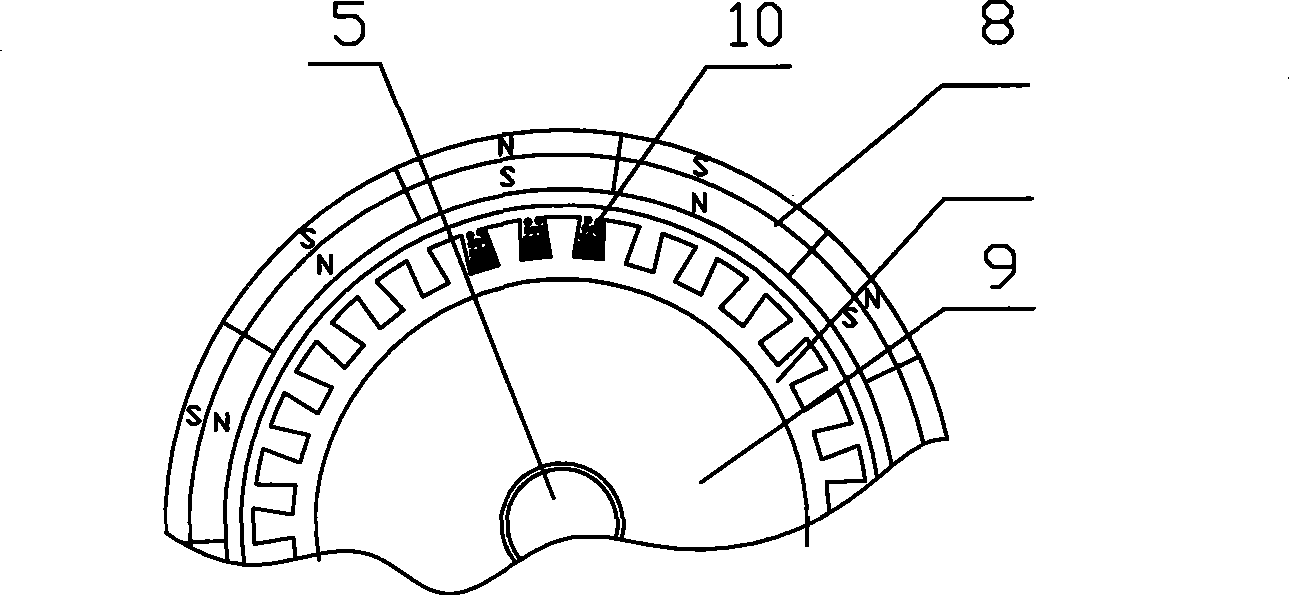

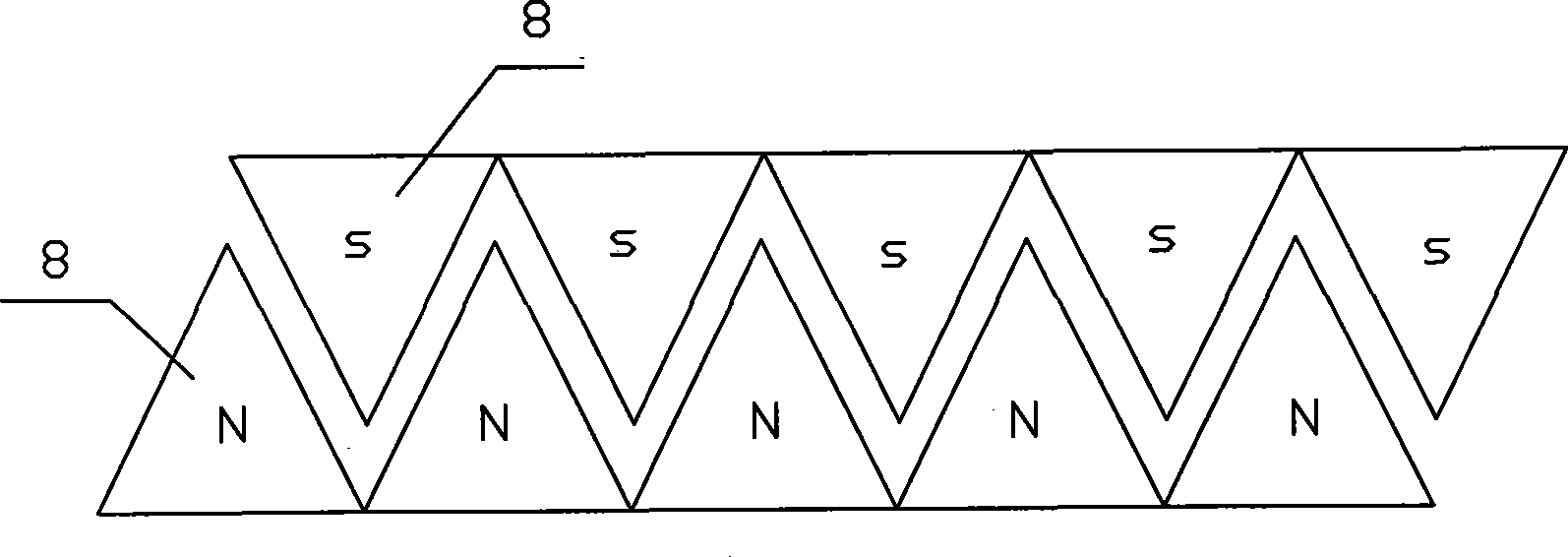

[0021] Fig. 1 is a cross-sectional view of an embodiment of the present invention, in order to express clearly, the section line in the figure is not drawn; As shown in Fig. The wind wheel 2 is installed on the front end of the main shaft 3 . The rear end of the main shaft 3 is connected to the generator shaft 5 through a coupling 4, and the middle section of the generator shaft 5 is fixedly connected with a rotor support 6 through a flat key. The rotor support 6 is disc-shaped, and the generator shaft 5 is vertically inserted in the rotor Center of support 6. The outer ring of the rotor support 6 is fixedly connected to the rotor barrel 7; the rotor barrel 7 is a barrel-shaped part with a rotor frame 15 in the middle, and the rotor frame 15 is a partition arranged horizontally in the barrel cavity, and its center has a The mounting hole of the rotor support 6 is provided with a permanent magnet 8 on the inner wall of the drum cavity on both sides of the rotor frame 15 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com