Environment protection type heat resisting unsaturated polyester electrical plastic

An unsaturated, environmentally friendly technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., to achieve good mechanical and electrical properties and meet the effects of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

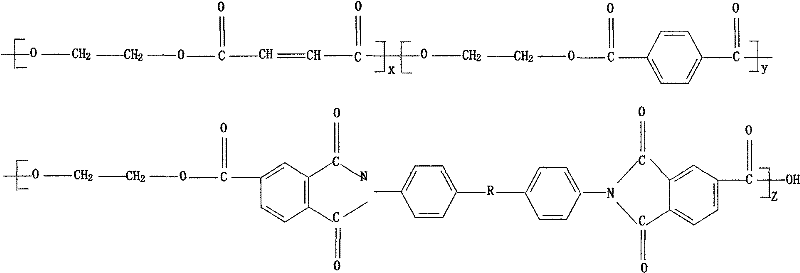

Method used

Image

Examples

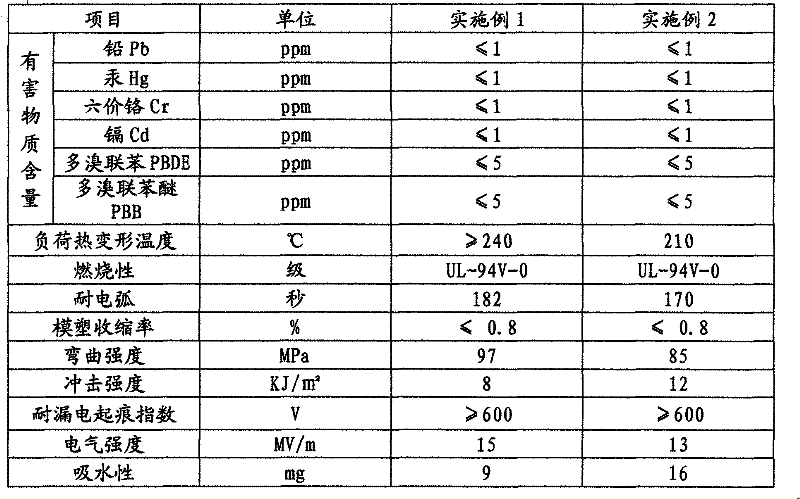

Embodiment 1

[0017] 30 parts by weight of imine modified heat-resistant unsaturated polyester resin, 5 parts by weight of dipropylene phthalate prepolymer; 5 parts by weight of bismaleimide, 20 parts by weight of alkali-free glass fiber; chopped nylon fiber 5 parts by weight; 15 parts by weight of magnesium hydroxide; 10 parts by weight of aluminum hydroxide; 5 parts by weight of melamine; 1.5 parts by weight of tert-butyl peroxide; 2 parts by weight of zinc stearate; 1.5 parts by weight of carbon black. The above-mentioned materials are weighed and added to a high-speed mixer to mix evenly, and then sent to a twin-screw mixing extruder for melting and mixing, and the temperature of the barrel is controlled at 90-110°C. After mixing, enter the single-screw extruder granulator for extrusion and hot granulation; then cool, sieve, batch mix, magnetically separate and package to obtain an environmentally friendly heat-resistant polyester electrical plastic. Its performance indicators are shown...

Embodiment 2

[0019] 30 parts by weight of imine-modified heat-resistant unsaturated polyester resin, 8 parts by weight of dipropylene phthalate prepolymer; 2 parts by weight of bismaleimide, 15 parts by weight of alkali-free glass fiber; chopped nylon fiber 10 parts by weight; 10 parts by weight of magnesium hydroxide; 10 parts by weight of aluminum hydroxide; 10 parts by weight of melamine; 1.5 parts by weight of tert-butyl peroxide; 2 parts by weight of zinc stearate; 1.5 parts by weight of carbon black. The above-mentioned materials are weighed and added to a high-speed mixer to mix evenly, and then sent to a twin-screw mixing extruder for melting and mixing, and the temperature of the barrel is controlled at 90-110°C. After mixing, enter the single-screw extruder granulator for extrusion and hot granulation; then cool, sieve, batch mix, magnetically separate and package to obtain an environmentally friendly heat-resistant polyester electrical plastic. Its performance indicators are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com