Tail fiber coupling output device of laser diode array / surface array

A laser diode, coupling-out technology, applied in the coupling of optical waveguides, lasers, laser parts and other directions, can solve the problems of difficult adjustment, complex optical shaping devices, and high production costs, and achieve simplified process, huge economic potential, principle and Simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

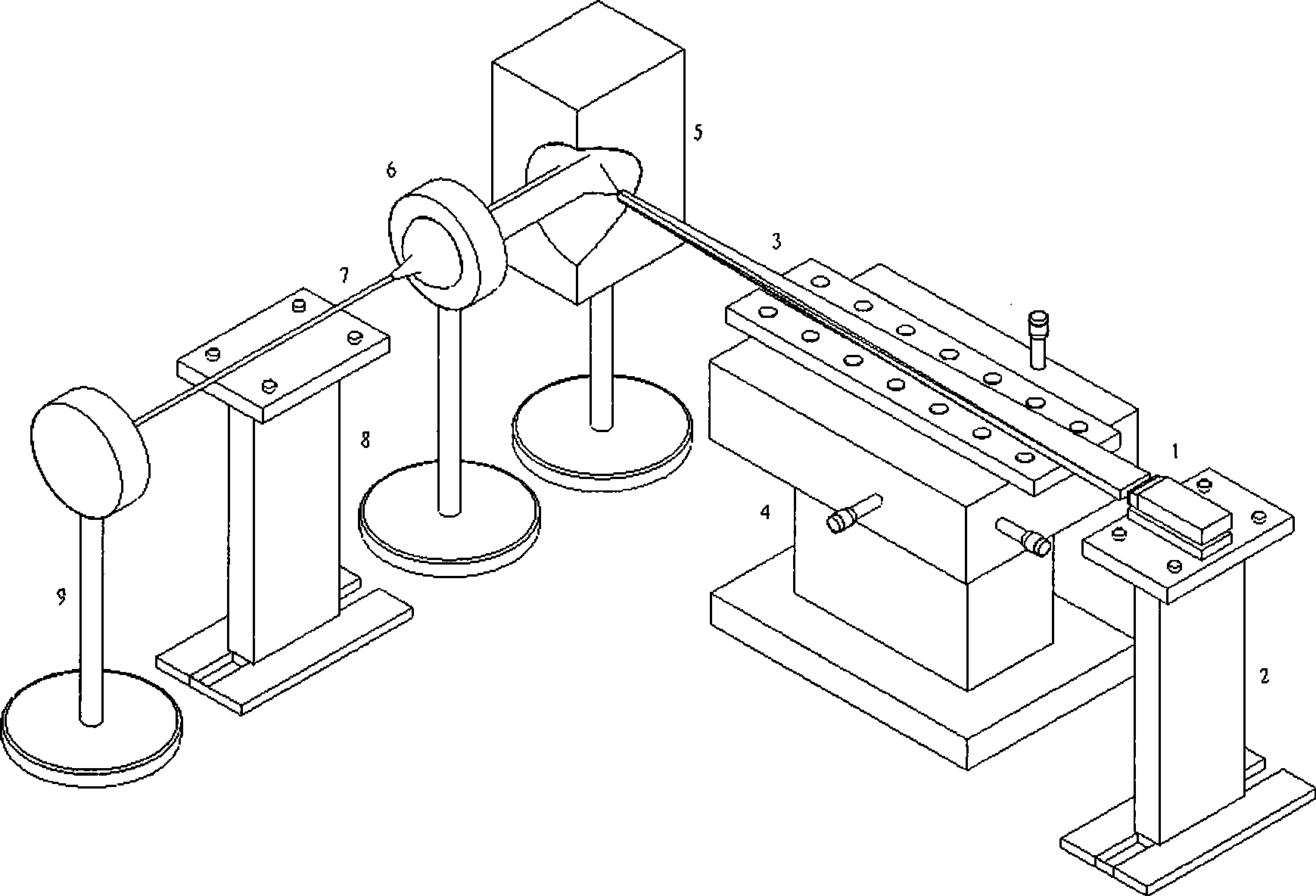

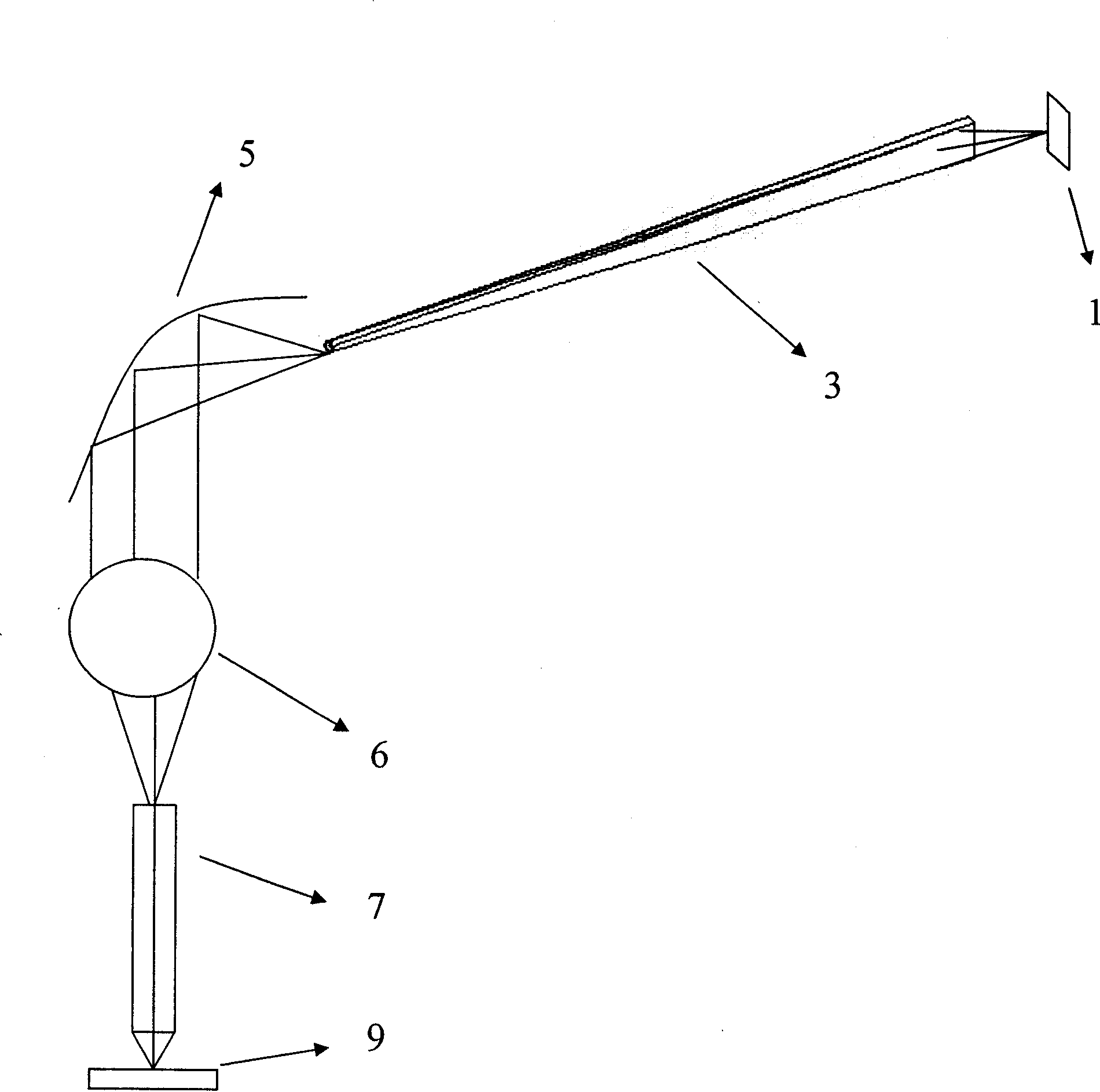

[0025] A pigtail fiber coupling output device with fast axis collimation laser diode array, see figure 1 . The devices used in this device are: laser diode array 1 with fast axis collimation; laser platform support 2; optical fiber taper 3 with long input end face; precision three-dimensional adjustment platform 4; the first parabolic reflector The parameter of 5 is p=4; the curvature radius of the first spherical focusing lens 6 is 3 mm, the single-mode optical fiber 7 , and the optical fiber fixing bracket 8 .

[0026] The connection between the above devices constituting the device: the light-emitting surface of the laser diode array 1 with fast axis collimation is close to the input end face of the optical fiber tapered body 3 whose input end face is elongated; the input end face is elongated optical fiber The end of cone 3 is positioned at the focal point of first parabolic mirror 5; The light beam collimated by the parabolic reflector 5 is focused; the single-mode fibe...

Embodiment 2

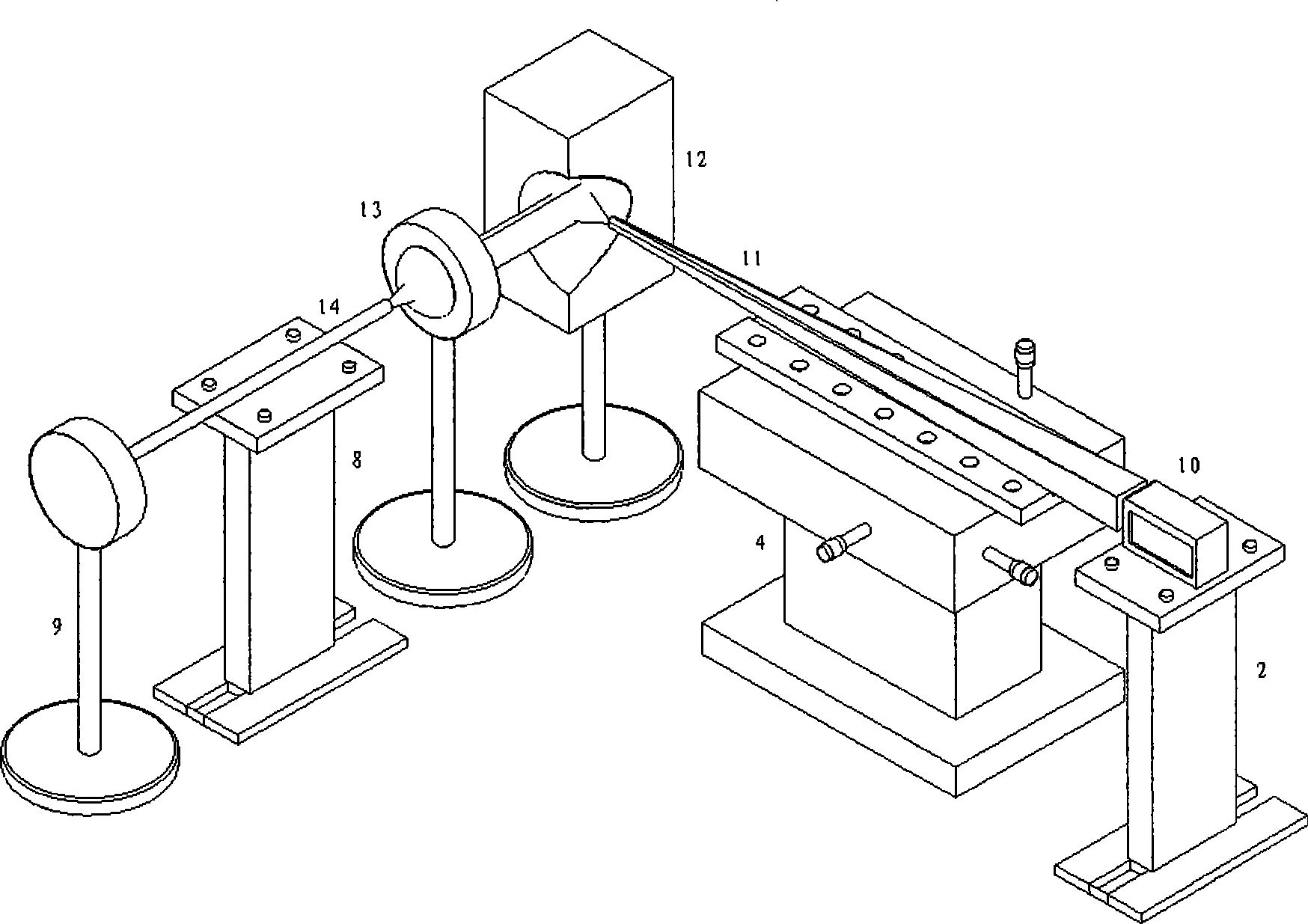

[0032] A pigtail fiber coupling output device with fast axis collimated laser diode area array, see figure 2 , 5 . The devices used in this device are: a laser diode array 10 with fast axis collimation, a laser platform support 2, an optical fiber cone 11 with a square input end face, a precision three-dimensional adjustment platform 4, and a second parabolic reflector 12. The parameter p=8, the radius of curvature of the second spherical focusing lens 13 is 6 mm, the diameter of the double-clad optical fiber 14 is 300 um, and the optical fiber fixing bracket 8 .

[0033] The optical fiber tapered body 11 with a square input end face uses an optical fiber drawing tower to carry out reverse drawing processing on a square optical fiber preform with a side length of 14mm in cross section. Rod uniformly reduced to a bare fiber with a diameter of 400um and a total length of 30cm ( figure 2 , 5 ), the diameter change is linearly proportional to the length of the optical fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com