Manufacturing method of double diffusion field effect transistor

A field-effect transistor and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of rapid drop in device breakdown voltage, large saturation current, saturation current and breakdown voltage of double-diffusion field-effect transistors It is difficult to optimize between the problems, so as to reduce the leakage current, increase the saturation current, and improve the withstand voltage characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

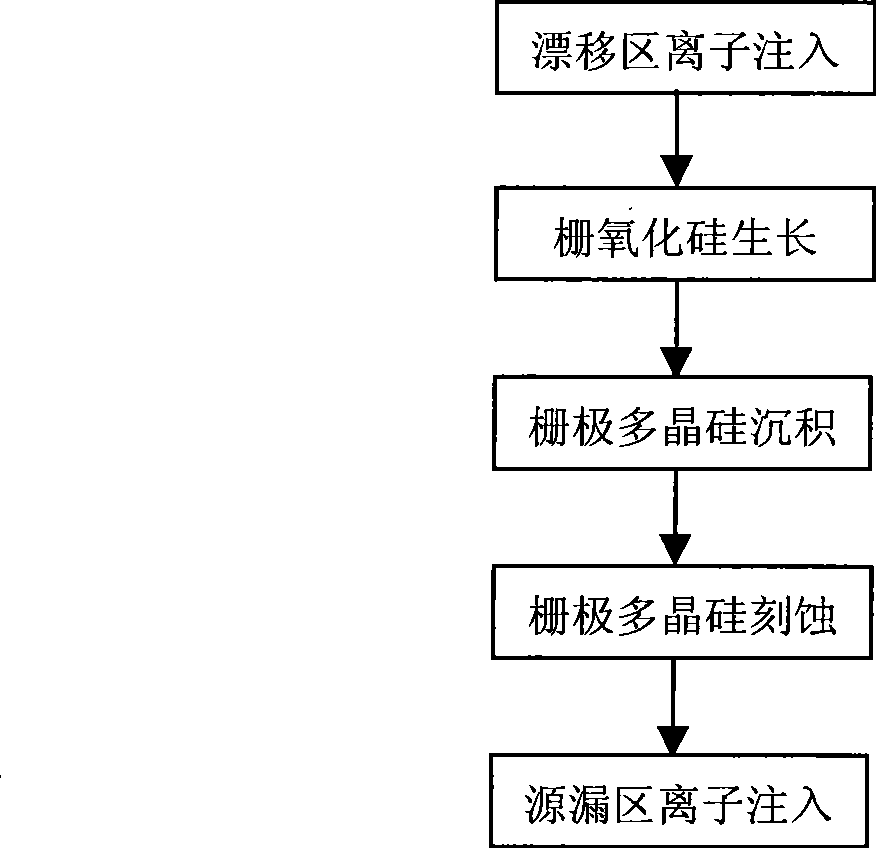

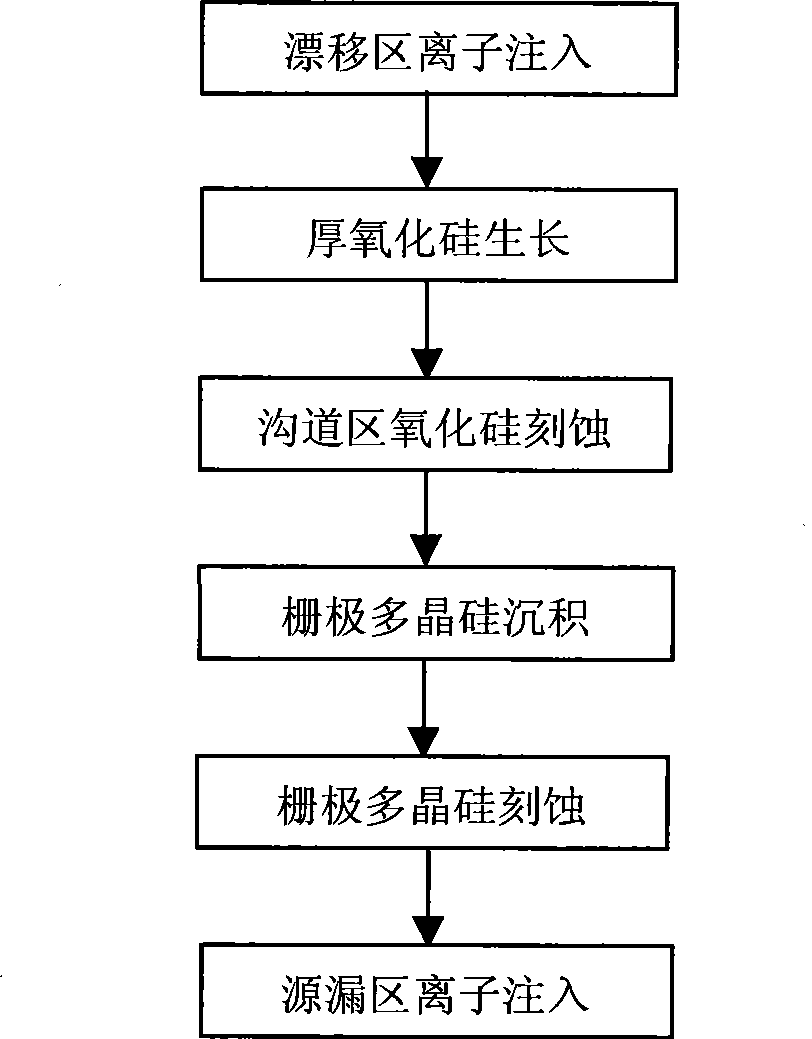

[0026] In one embodiment, such as image 3 Shown, method of the present invention comprises the following steps:

[0027] The first step is to carry out ion implantation on the silicon substrate to form a well region. Those skilled in the art should know that if the transistor to be manufactured is an N-type transistor, the ions to be implanted should be boron ions; The transistor to be manufactured is a P-type transistor, and the ions to be implanted at this time should be phosphorous ions.

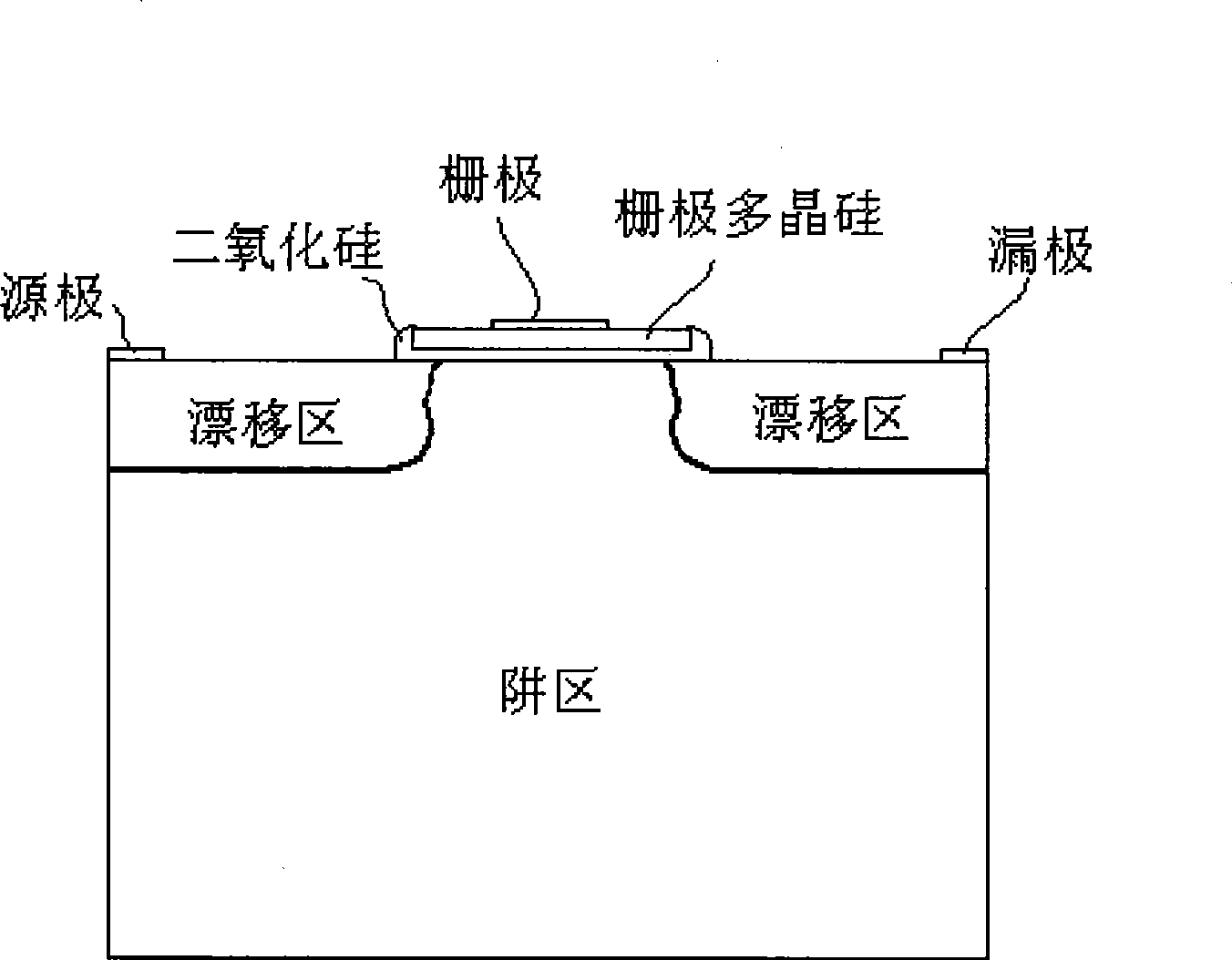

[0028] In the second step, selective ion implantation is performed at the position of the well region of the silicon substrate to form a drift region, and the cross-sectional structure at this time is as follows Figure 4a shown. Those skilled in the art should know that if the transistor to be manufactured is an N-type transistor, the implanted ions should be phosphorus ions at this time; and if the transistor to be manufactured is a P-type transistor, the implanted ions should be fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com