Iron ion circulating electrode and preparation method thereof

A technology of iron ions and electrodes, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of low output power density and achieve the effect of increasing output power density

- Summary

- Abstract

- Description

- Claims

- Application Information

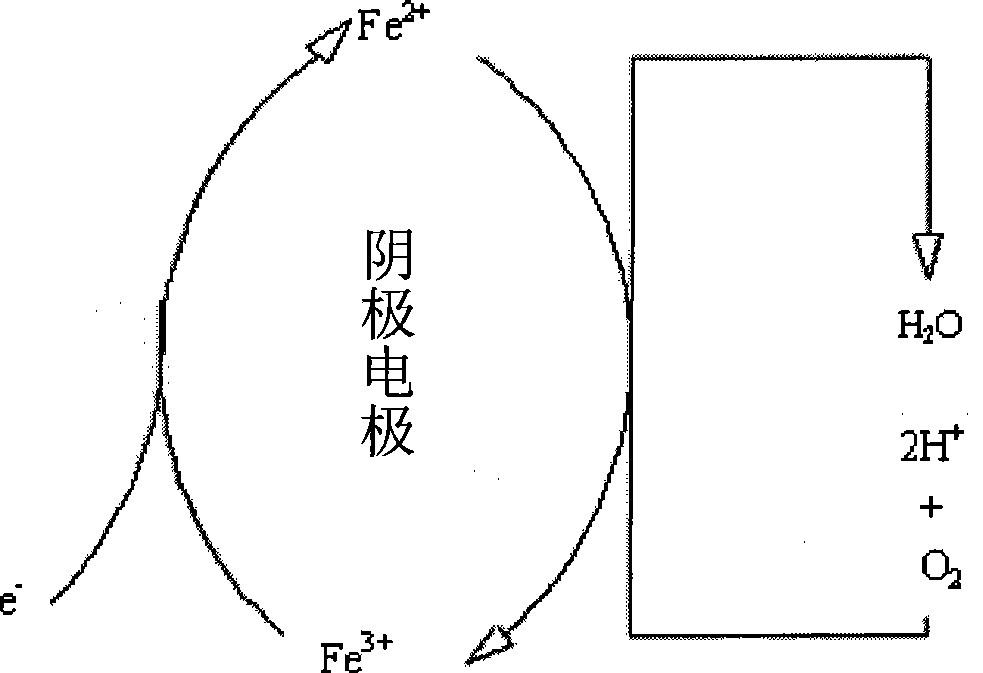

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

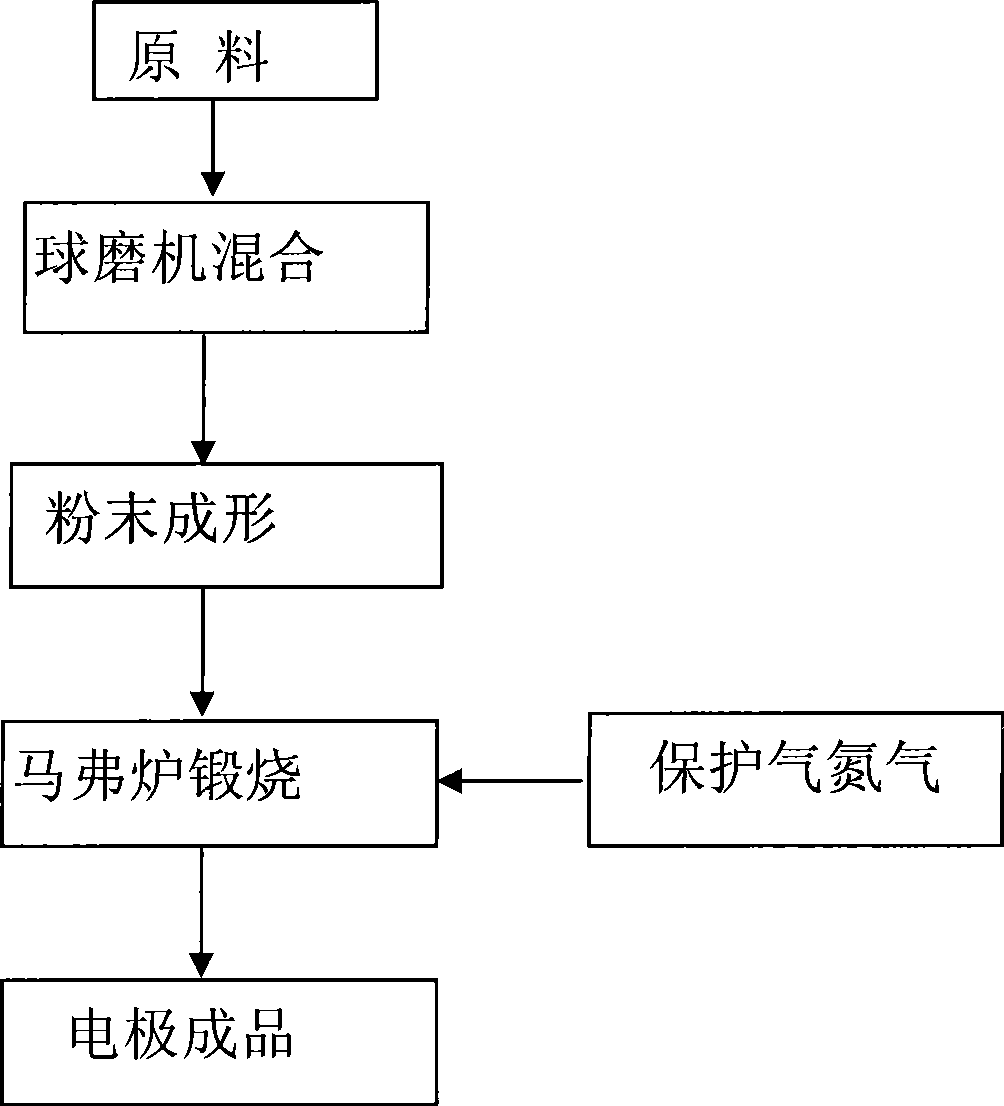

[0022] This example is used to illustrate the preparation method of the iron ion circulation electrode provided by the present invention.

[0023] The operation flow of this embodiment is as follows figure 2 shown. After mixing 15 grams of ferric sulfate, 300 grams of 400 mesh graphite powder, 175 grams of 500 mesh kaolin, 5 grams of nickel chloride and 5 grams of polyvinyl alcohol pellets with a diameter of 80 μm, the ball mill was milled for two days to make the powder evenly mixed, and then the dry The powder is directly put into a cylindrical mold with a section diameter of 8cm and a height of 9cm, at 20kgf / cm 2 (kgf / cm2) under pressure, press it into a circular thin plate with a diameter of 8 cm and a thickness of 5 mm, place the pressed thin plate in a muffle furnace, feed nitrogen, and calcine at a constant temperature of 1100 ° C for 12 hours , made of iron ion circulation electrode, and finally cut into a cuboid electrode with a size of 50mm×50mm×5mm.

[0024] The...

Embodiment 2

[0039] This example is used to illustrate the preparation method of the iron ion circulation electrode provided by the present invention.

[0040] The difference from Example 1 is that 5 grams of polyvinyl alcohol pellets with a diameter of 80 μm are replaced by 8 grams of polyethylene pellets with a diameter of 60 μm, and 15 grams of chloroform are added to the mixture after ball milling, and then put into the mold after mixing In, other operating conditions and steps are identical with embodiment 1. The total volume of pores measured according to the method described in Example 1 is 15% of the total volume of the electrode prepared in this example.

Embodiment 3

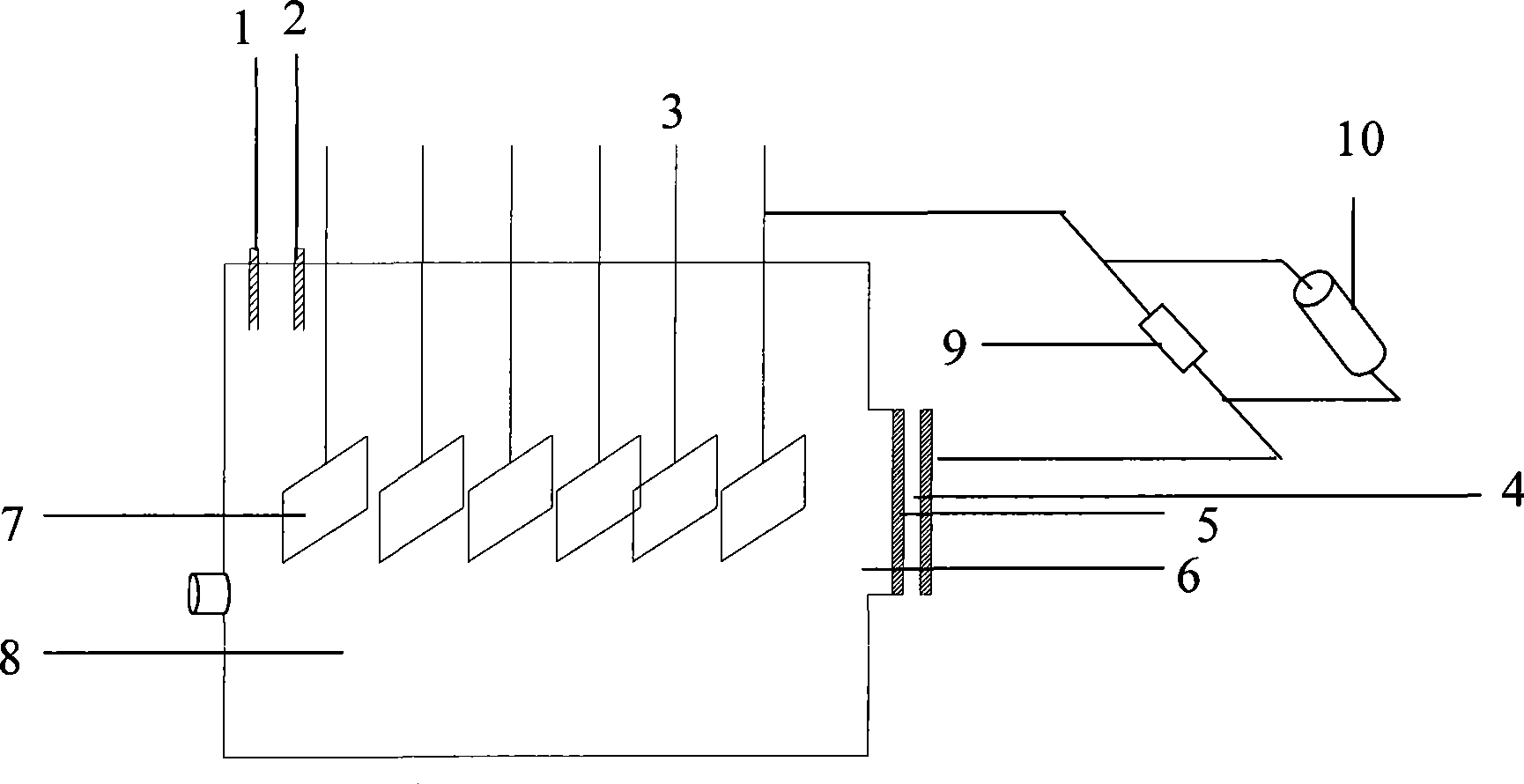

[0045] This example is used to illustrate the method for preparing a microbial fuel cell using the iron ion circulating electrode prepared in Example 1 as a cathode.

[0046] Such as image 3 As shown, a cuboid plexiglass container with a size of 15cm (length) × 12cm (width) × 8cm (height) is used as the anode chamber of the battery, and the top of the container is a detachable cover plate with 8 small holes. Wherein 3 is the electrode wire outlet (6 wire outlets), 1 is the gas inlet, and 2 is the gas outlet. Open a stepped square window 6 on one side of the container, its outer layer size is 5cm, and the inner layer size is 4cm, and 4 screw holes are set around the window, using the screw holes, the made in Example 1 The iron ion circulation electrode is fixed on the window 6 as the cathode, and the proton exchange membrane 5 (Nafion-117, Dupont) is used to separate the cathode electrode plate 4 and the anode chamber 8, and a vacuum pad is used between the proton exchange me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com