Sugarless poly-glucose and production method thereof

A technology of polydextrose and anhydrous glucose, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of no sugar-free polydextrose production method, unsuitable for diabetic patients, inconvenient promotion and application, etc., and achieves good product performance and taste. , the effect of low residual monosaccharide content and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

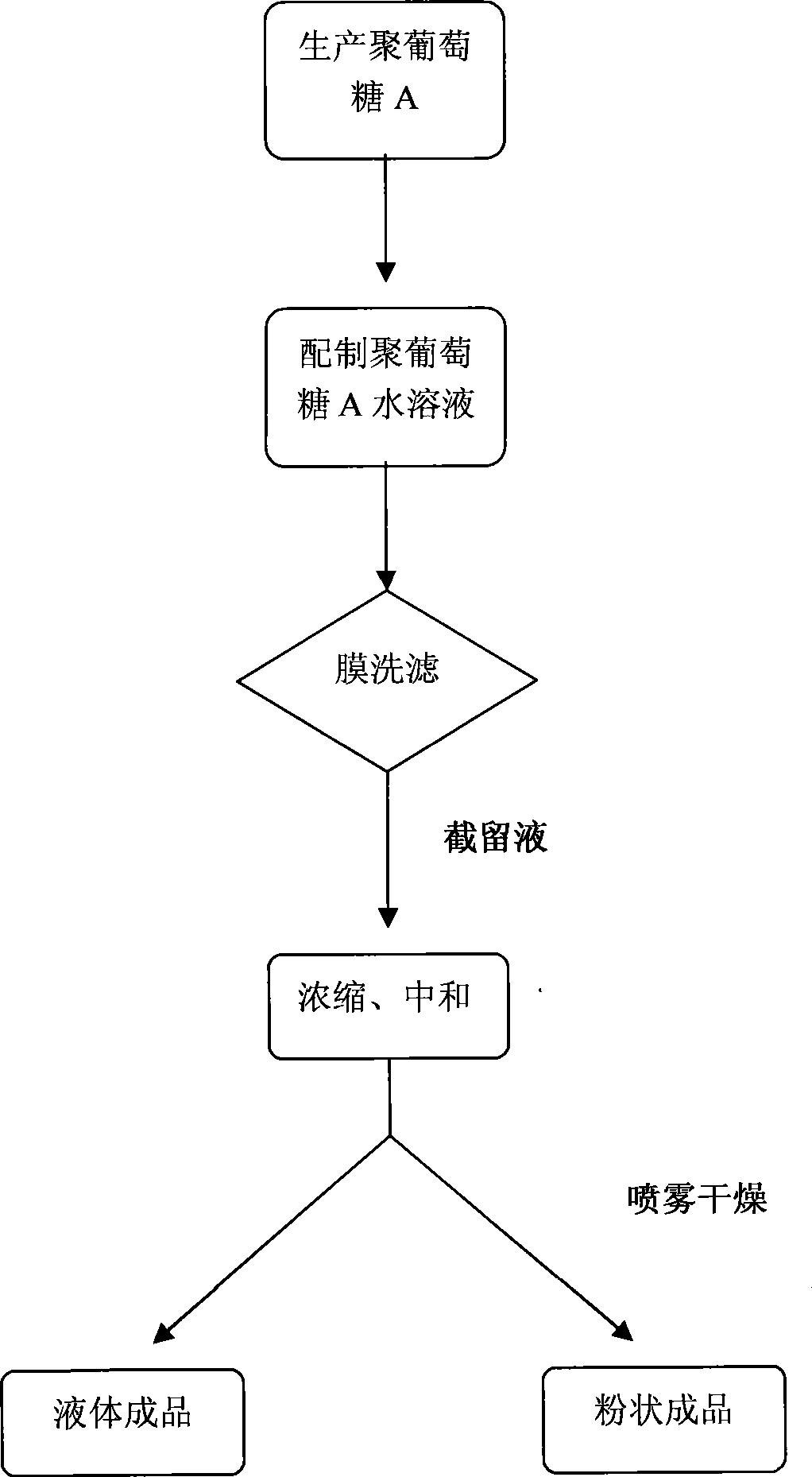

Image

Examples

Embodiment 1

[0031] Example 1 The production process of polydextrose A

[0032] 267kg of oral dextrose, 30kg of food-grade D-sorbitol and 3kg of food-grade citric acid in water, mixed thoroughly, added to a specially made 500L stainless steel polymerization kettle, and reacted for 4 hours at 140°C to 180°C under a pressure of less than 300mHg. Obtain polydextrose A type product.

Embodiment 2

[0033] Example 2 The production process of polydextrose A aqueous solution

[0034] Add 2700kg of pure water into a stirring and jacketed stainless steel dissolution kettle, preheat it to 40°C with steam, add 300kg of polydextrose A raw material under stirring, and stir until it is completely dissolved to obtain a 10% polydextrose A aqueous solution .

Embodiment 3

[0035] Example 3 Production process of sugar-free polydextrose

[0036] With the 10% polydextrose A aqueous solution produced in Example 2, on the nanofiltration membrane unit, at 40 ° C, under the pressure of 17.4 to 22.5 bar, first circulate and pre-concentrate to 1 / 2 of the volume, then wash and filter, and divide For the second time, pure water is added each time to make up to the volume of the raw material solution, and the final diafiltration concentration reaches more than 21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com