Method for separating and purifying cobalt solution by extraction chromatography

A chromatographic separation and cobalt solution technology, applied in the direction of improving process efficiency, can solve problems such as difficulty in preparing high-purity cobalt solution, difficulty in realizing deep separation of cobalt-nickel, cobalt-copper, etc., to reduce irritating odor and reduce investment. , the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

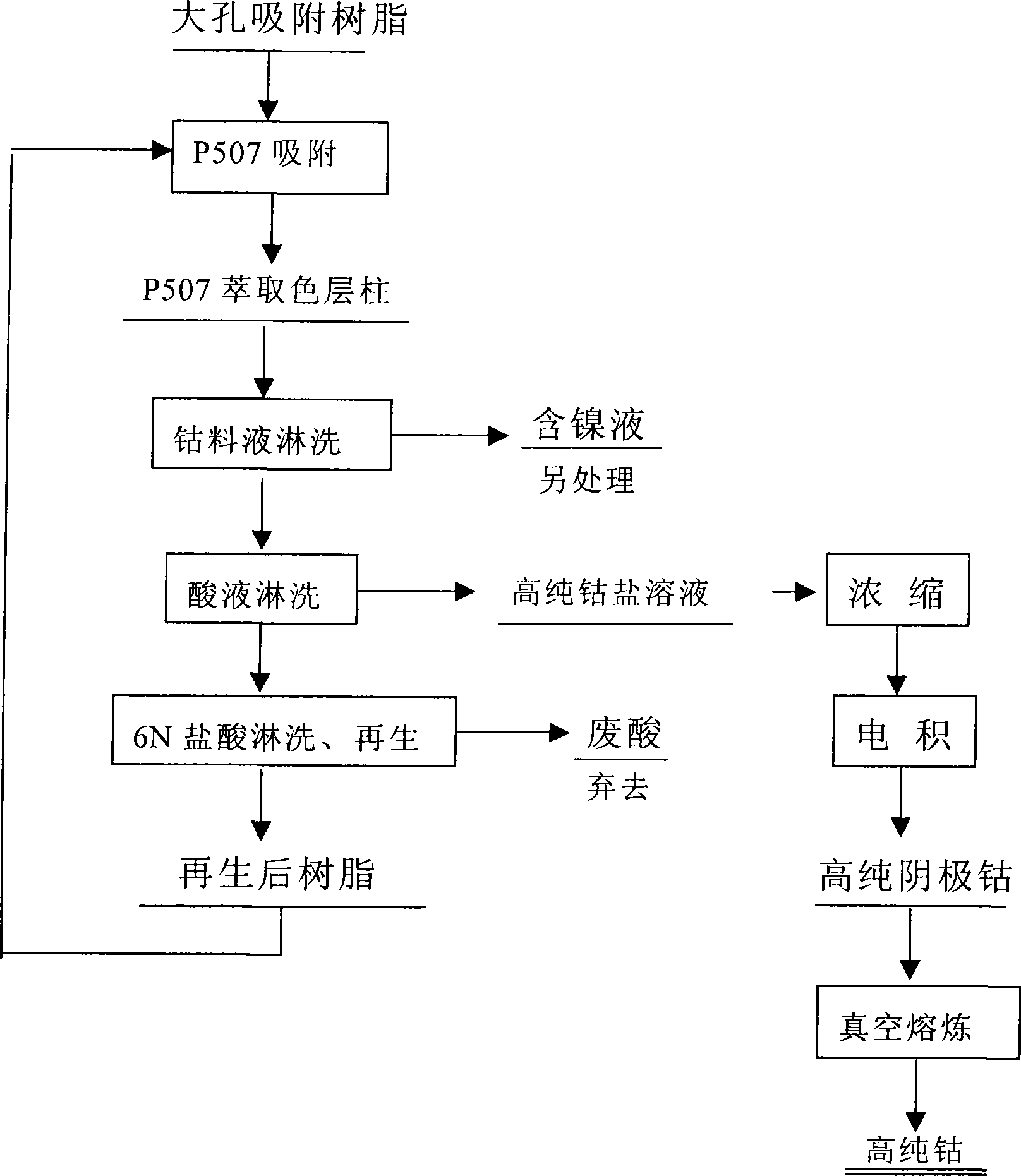

[0033] like figure 1 As shown, take 10 kg of water-containing macroporous adsorption resin (particle size between 70-150 mesh) into the aqueous solution, add 2 kg of P507 (2-ethylhexyl phosphate-2-ethylhexyl ester) extractant , carried out adsorption treatment under the condition of stirring, prepared 34% P507 extraction resin after filtration, packed into a plexiglass column with a diameter of 80 mm and a length of 850 mm, and assembled into a P507 extraction resin column.

[0034] Add 5 liters of cobalt chloride feed liquid, wherein the cobalt concentration is 60 g / L, the pH value of the feed liquid is 4.5, and the P507 extraction resin column is rinsed until the pH value of the eluate is 3.

[0035] Then with cobalt-containing 5 grams per liter, the cobalt chloride solution that the pH value is 2 rinses the P507 extraction resin that loads cobalt, when the eluate volume is 4 times of the chromatographic column void volume, use acidity instead as 2 Mole / L hydrochloric acid ...

Embodiment 2

[0039] The test operation method is the same as in Example 1. A 50% TBP extraction resin was prepared. Add 5 liters of cobalt sulfate feed solution, wherein the cobalt concentration is 80 g / L, the pH value of the feed solution is 4, and the P507 extraction resin column is rinsed until the pH value of the eluate is 3.

[0040] Then use the cobalt sulfate solution containing 8 g / L of cobalt and the pH value to be 2 to rinse the loaded P507 extraction resin. The sulfuric acid solution quickly elutes the cobalt ions adsorbed by the chromatography column.

[0041] Finally, regenerate and rinse the P507 extraction resin column. The regeneration solution is 6 mol / L hydrochloric acid solution. When the volume of the eluate is 4 times the void volume of the chromatographic column, use deionized water to rinse. It ends when the pH value of the leachate is 5.

[0042]The collected cobalt sulfate solution is concentrated to 90 g / L, and electrolytic deposition is carried out. The electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com