Method for detecting residual stress of steel by X-ray

A residual stress and X-ray technology, applied in the field of X-ray diffraction method to measure residual stress, can solve the problems of limited penetration depth, reduce application efficiency, weaken corrosion and peeling layers, etc., achieve strong regularity, improve measurement accuracy, and corrosion rate easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The method of measuring the residual stress of steel by X-ray has the following steps:

[0025] (1) Electrolytic corrosion

[0026] Take the galvanized sheet and polish the smooth surface;

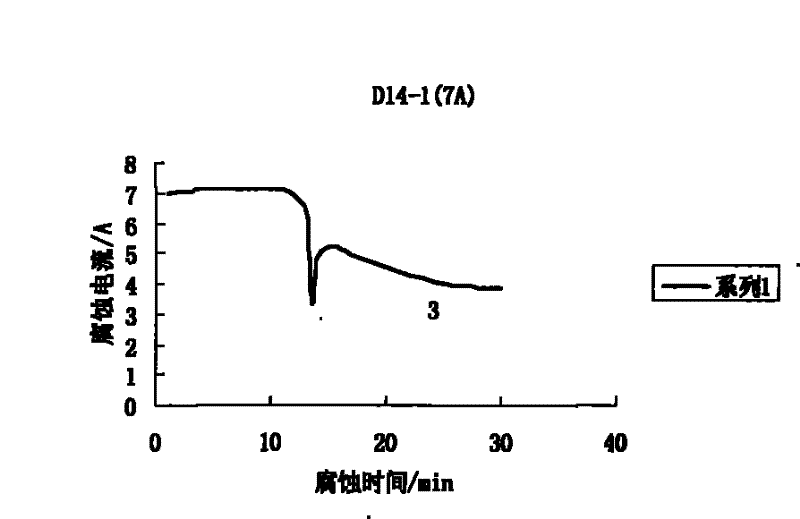

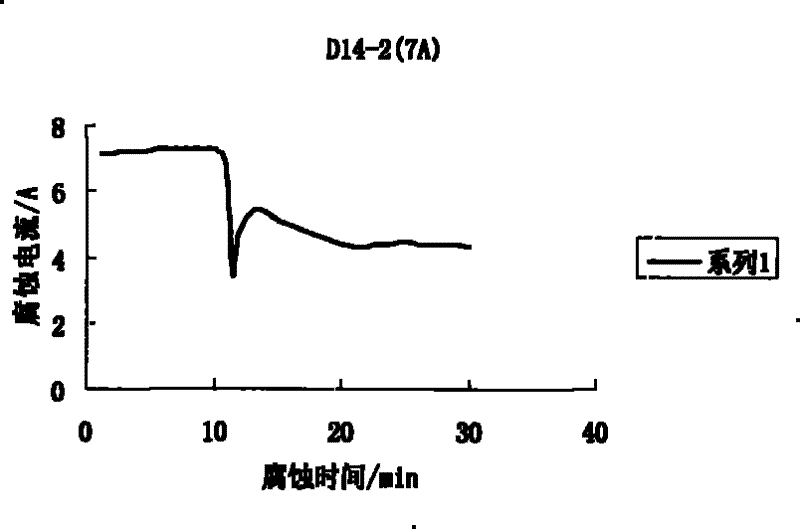

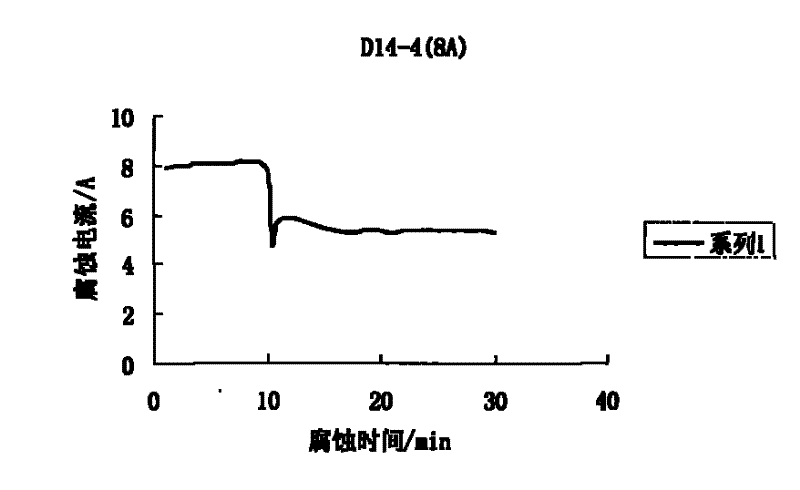

[0027] Saturated NaCl aqueous solution is the electrolyte, the component to be tested is used as the anode corrosion end, galvanized iron sheet is used as the cathode, DC constant voltage corrosion, the electrolytic corrosion time is set according to the required corrosion area and depth of the component, and the corrosion current is 7-8A;

[0028] (2) After corrosion and peeling, use an X-ray stress meter to measure the residual stress in the vertical direction of the weld, and then use the method of single-sided peeling to measure the stress value correction method to correct the measured value of the residual stress after peeling, that is, the steel Residual Stress.

[0029] The present invention takes the weldment of 921A steel plate as an example to carry out the electrochemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com