Method for enhancing self-aligning contact hole breakdown voltage and polysilicon gate construction

A technology of self-aligned contact holes and polysilicon gates, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., and can solve the loss of sidewall dielectric materials, the damage of through-hole etching process, and the distance from the top corner of the gate to the through-hole Shrinkage and other issues, to increase the distance, improve the effect of breakdown voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

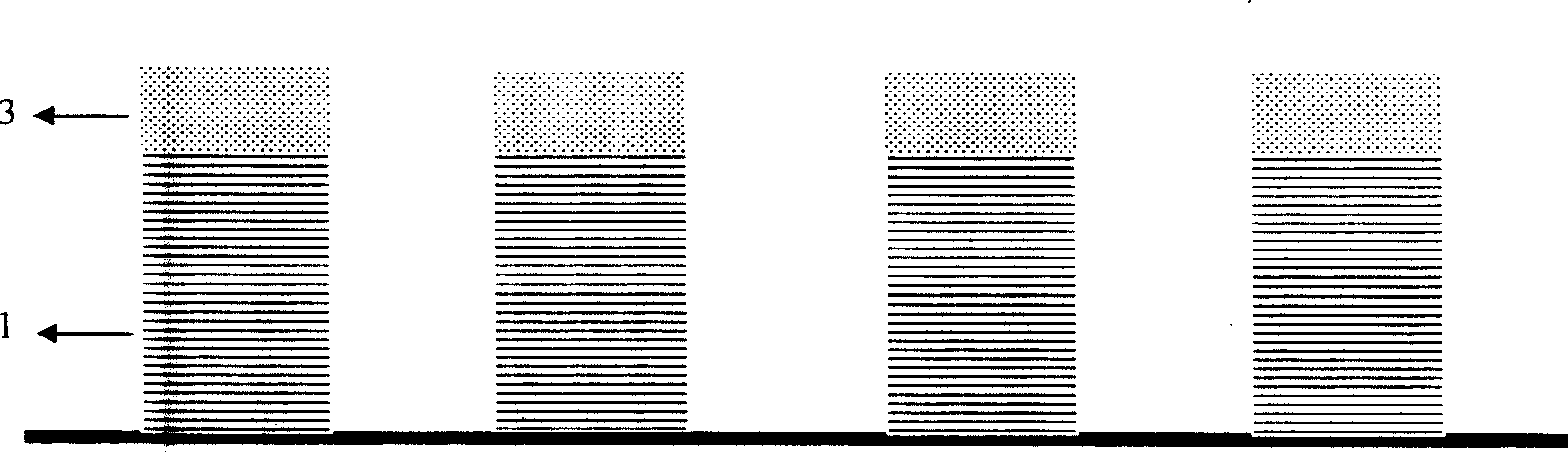

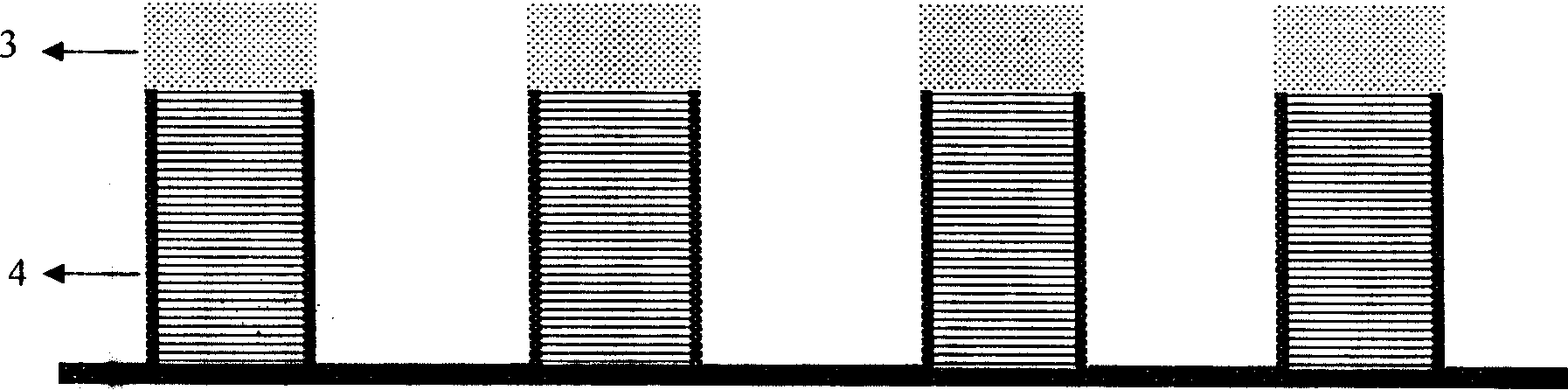

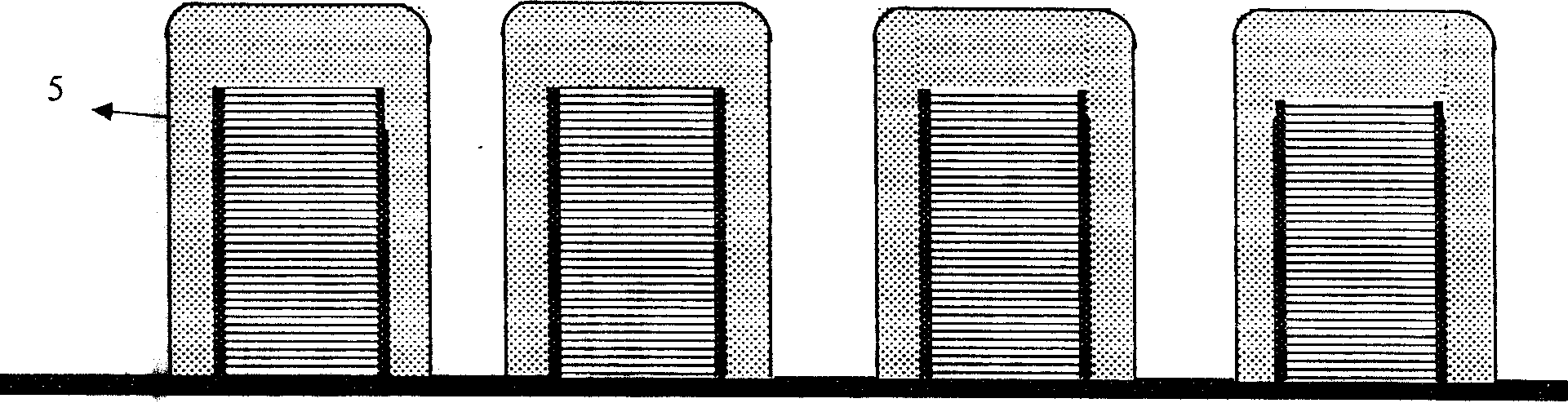

[0017] Such as Figure 5 Shown, the present invention comprises the following steps:

[0018] First, polysilicon, an oxide film and a hard mask layer are sequentially deposited on the oxide layer on the silicon substrate. The hard mask layer is generally a silicon nitride thin film material, and its thickness is generally 300 angstroms to 3000 angstroms. The deposited oxide film is silicon oxide, which can be deposited by high temperature oxide film, chemical vapor deposition oxide film and other methods. The deposited silicon oxide film generally has a thickness of 80 angstroms to 400 angstroms. This layer of oxide film will help to round the top tip of the gate in the subsequent process flow.

[0019] After coating photoresist and photolithography, the hard mask layer, oxide film layer and polysilicon are sequentially etched from top to bottom. During this etching process, plasma etching or chemical wet etching or a combination of plasma etching and chemical wet etching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com