Electrode composition, method of making the same, and lithium ion battery including the same

An electrode composition, lithium-ion battery technology, applied in the direction of electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as complex and lengthy processes, and achieve the effect of relatively low cost, easy manufacture, and good operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

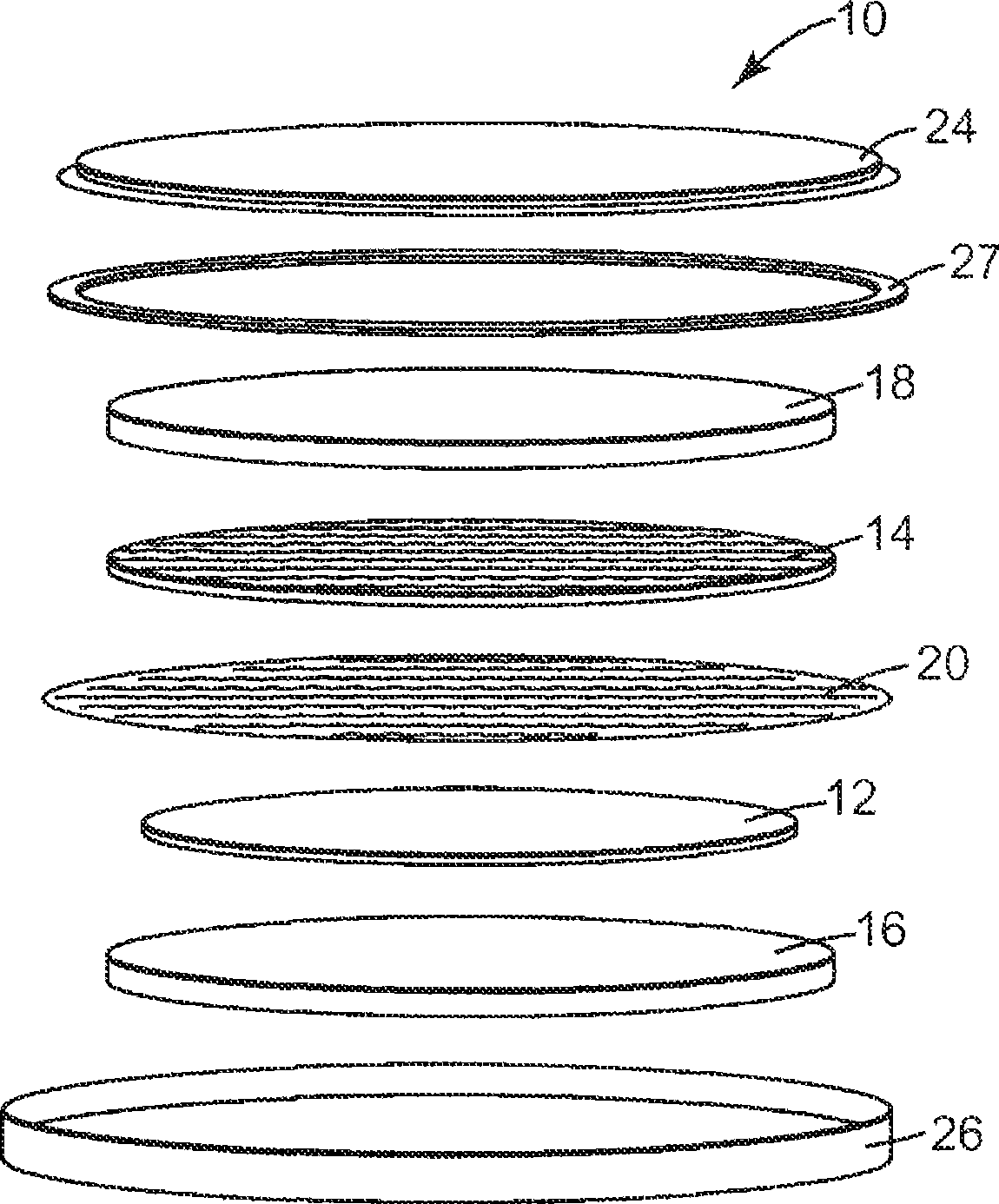

Image

Examples

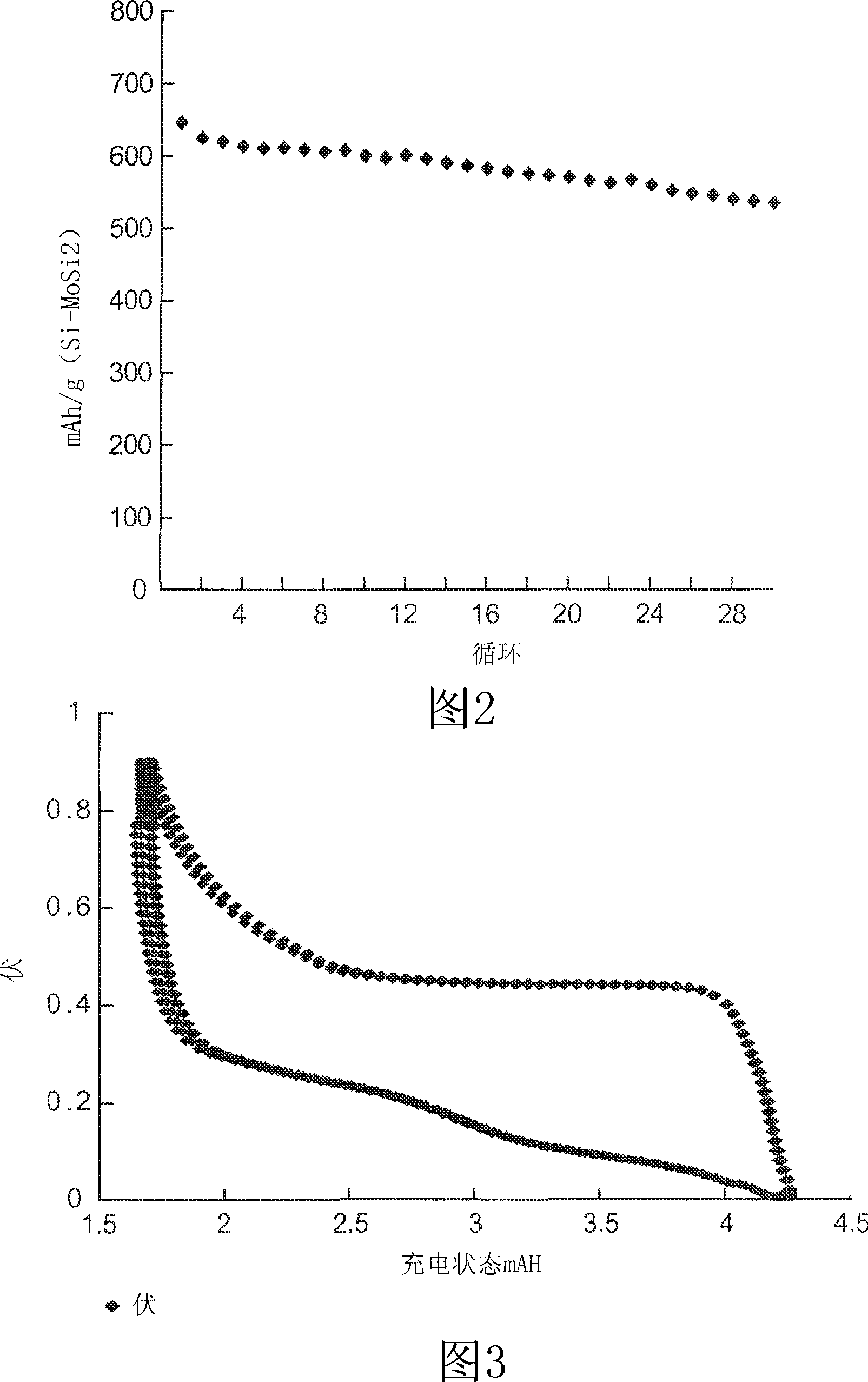

example 1

[0081] Silicon powder (0.3 grams (g), Alfa Aisha, particle size = 1-20 microns) and 1.4 g MoSi 2 (Cerac Incorporated, Milwaukee, Wisconsin, Cerac Incorporated, Milwaukee, Wisconsin, particle size = -325 mesh) was placed in a 30 milliliter (mL) planetary micromill under the trade name "PLANETARY MICRO MILLPULVERISETTE 7" was obtained from Fritsch, Idar-Oberstein, Germany, equipped with a tungsten carbide container and 51 g of 5 mm tungsten carbide grinding media, milled for 1 hour under heptane at speed setting 6 . To this mixture was added 0.255 g of high specific surface area carbon, available under the trade designation "SUPER P" from Timcal, Brussels, Belgium. Then, a polyimide precursor solution (0.85 g, 20 wt% solids in N-methylpyrrolidone (NMP)) was added to the solid mixture, followed by an additional 3 g of NMP. The polyimide precursor solution was commercially available as The name "PYRALIN PI 2555" was obtained from HD Microsystems, Wilmington, Delaware. Then, the...

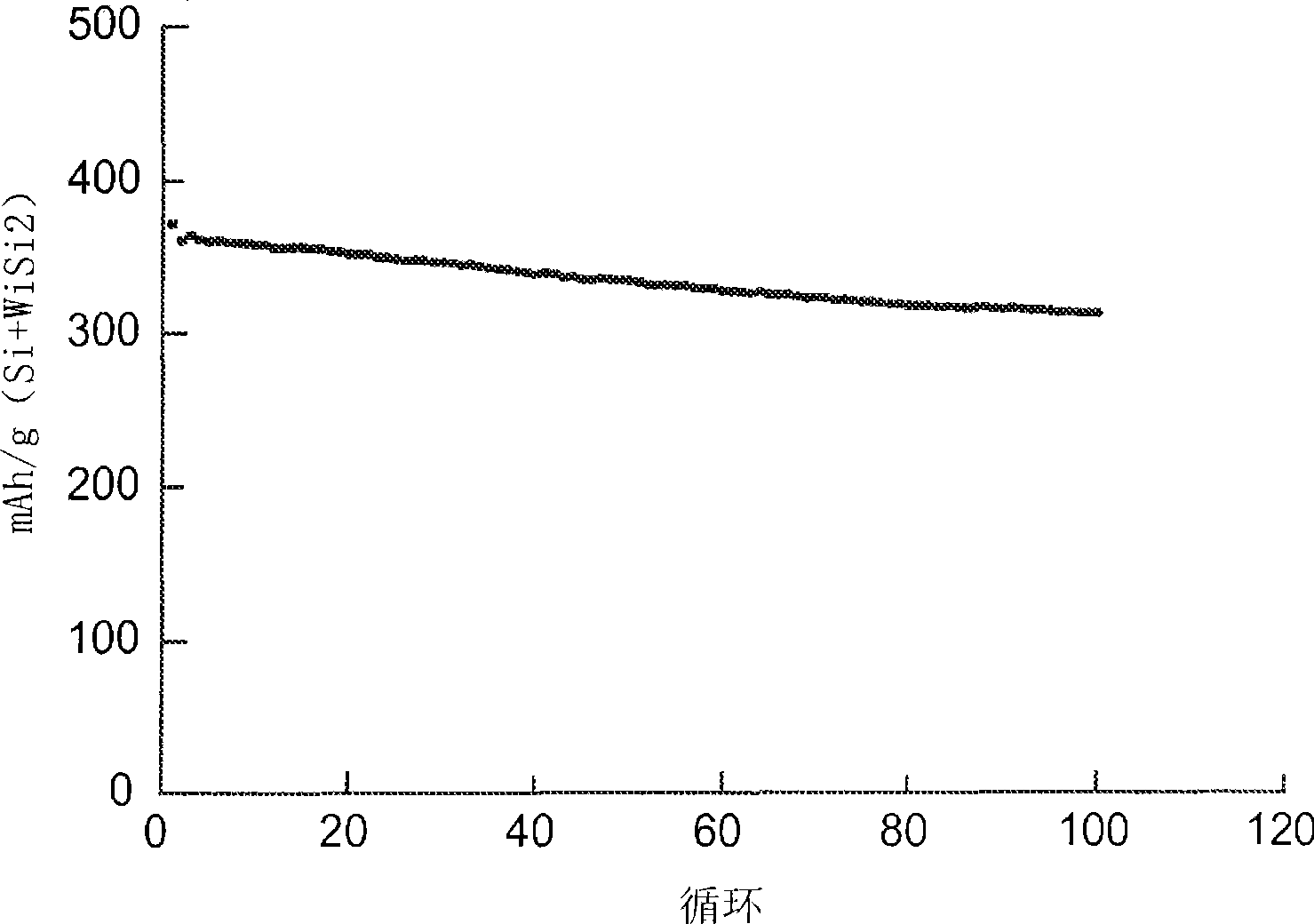

example 2

[0085] Silicon powder (0.3g, Alfa Aisha, particle size = 1-20 micron) and 2.08g WSi 2 (Alpha Aisha, particle size=-325 mesh) is placed in the planetary micro mill of 30 milliliters (mL), and planetary micro mill is obtained from Fritz Company with trade name " PLANETARY MICRO MILL PULVERISETTE 7 ", and it is equipped with Tungsten carbide container and 51g of 5mm tungsten carbide grinding media. The powder was milled under heptane at speed 10 for 2 hours. To this mixture was added 5.2 g of a 4.9% by weight dispersion of high surface area carbon in NMP, and 0.85 g of a polyimide precursor solution (20% by weight solids in NMP), high surface area carbon under the trade name "SUPER P" was obtained from Timcal Corporation, and the polyimide precursor solution was obtained from HD Microsystems under the trade designation "PYRALIN PI2555". The slurry was further mixed in a micromill at speed 3 for an additional 1 hour. The resulting slurry was coated onto nickel foil using a 5 mi...

example 3

[0088] Silicon powder (0.3g, Alfa Aisha, particle size = 1-20 micron) and 2.08g TSi 2(Alfa Aisha, particle size=-325 mesh) was placed in a 30 mL planetary micromill obtained from Fritz under the trade name "PLANETARY MICRO MILL PULVERISETTE 7" equipped with a tungsten carbide container and 51g of 5mm tungsten carbide grinding media. The powder was milled under heptane at speed 10 for 2 hours. In this mixture, add the dispersion of the high specific surface area charcoal of 4.9% by weight in NMP of 5.2g and 0.85g polyimide precursor solution (solid of 20% by weight in NMP), high specific surface area carbon is commercialized The name "SUPER P" is available from Tramicol Corporation, and the polyimide precursor solution is available from HD Microsystems under the trade designation "PYRALIN PI 2555". The slurry was further mixed in a micromill at speed 3 for an additional 1 hour. The resulting slurry was coated onto nickel foil using a 5 mil (0.1 mm) notched bar. The coated e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com