Non-toxic, environmental friendly, anti-corrosive, water proof, anti-seepage and wearable reinforcement material and preparation method thereof

A reinforcing material, waterproof and impermeable technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Low, easy to produce, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

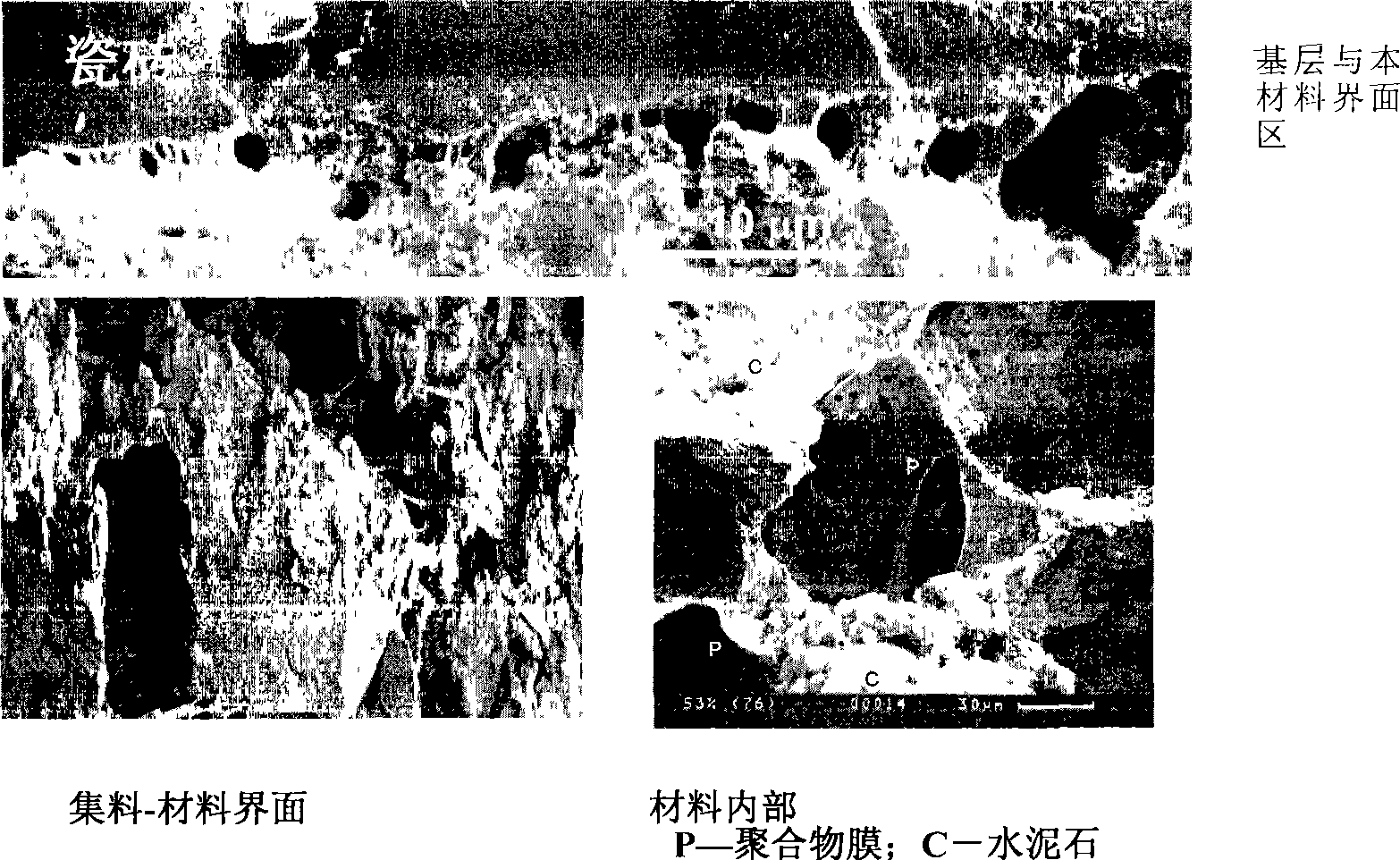

Method used

Image

Examples

Embodiment 1

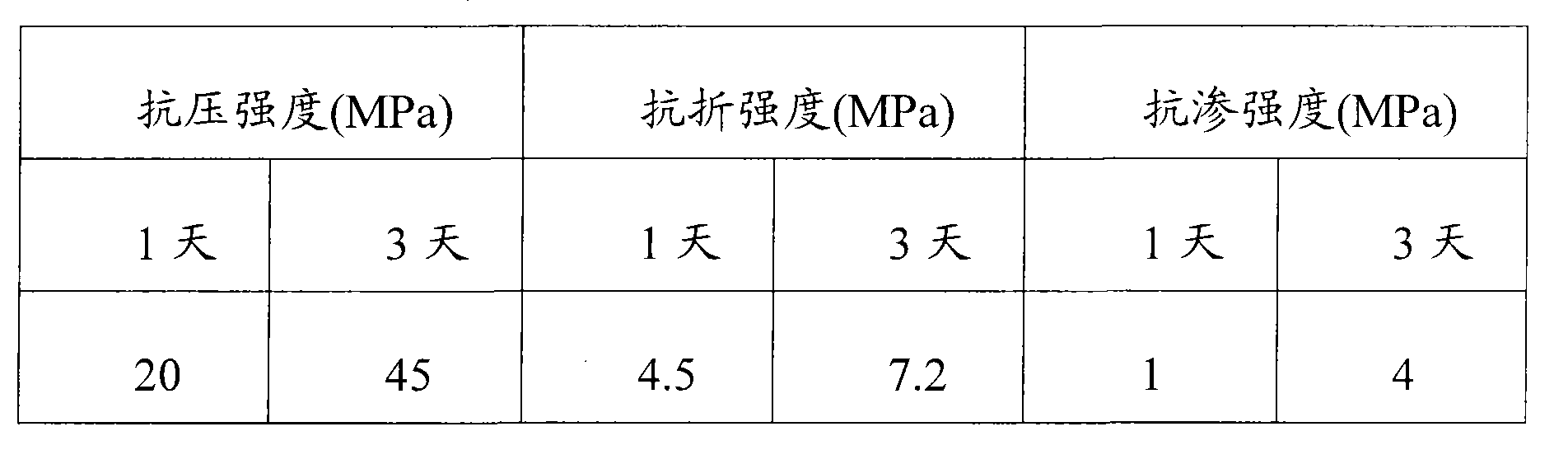

[0044] The non-toxic and environment-friendly anti-corrosion, waterproof, impervious and wear-resistant reinforcement material consists of: cationic acrylate rubber powder: modified complexed calcium: nano-active SiO 2 White carbon black: organosilicon modified nano-bentonite: KH560 silane coupling agent: finely ground sulphoaluminate cement clinker: polycarboxylate nonionic surfactant: quartz sand=8:6:20:4:0.2:200 :0.8:300.

[0045] Wherein, the cationic acrylate rubber powder is FLEX8300 cationic acrylate rubber powder produced by American National Starch Company.

[0046] The modified complex calcium is prepared according to the method described above, and its proportion is: silane coupling agent of ammonium benzyl: water: CaO = 1: 10: 100 (mass ratio).

[0047] The nano-active SiO 2White carbon black is prepared according to the method described above, and its proportioning ratio is 8:100 (mass ratio).

[0048] The organosilicon-modified nano-bentonite is prepared accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com