Alumina ceramic injection molding wax based polyethylene multi-polymer bonding agent

An alumina ceramic and injection molding technology, which is applied in the field of wax-based polyethylene multi-polymer binder, can solve the problems that it is difficult to prepare ceramic parts with small volume, complex shape and dimensional accuracy, and limit the application field of ceramics, so as to achieve the reduction of defects , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention is illustrated below by specific examples.

[0009] The wax-based polyethylene polymer binder for alumina ceramic injection molding of the present invention is composed of paraffin, low-density polyethylene and stearic acid, and its component and volume ratio are: paraffin: low-density polyethylene: Stearic acid=60:20:14. .

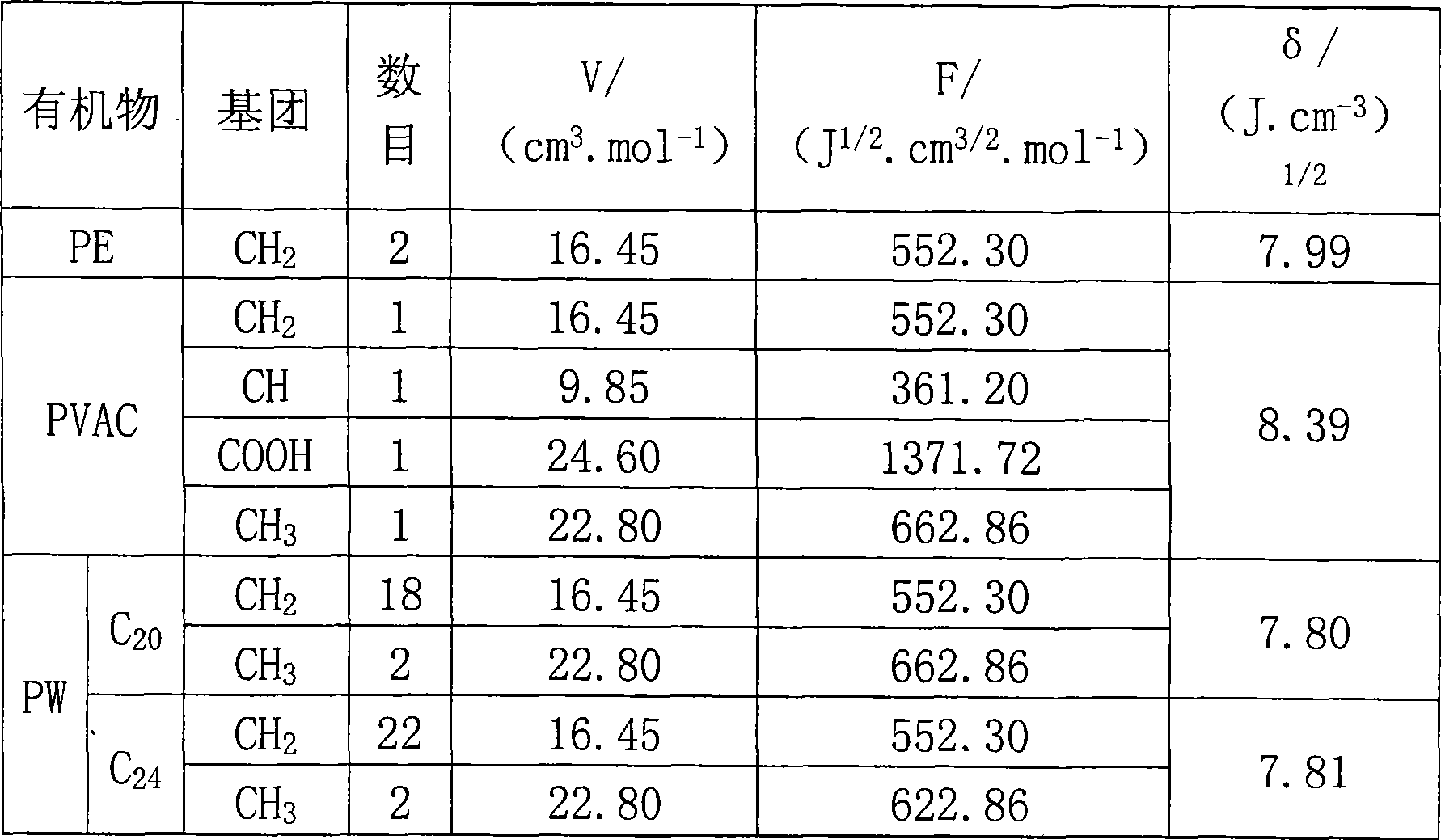

[0010] Compatibility between polymer binders in injection molding or between polymers and plasticizers and lubricants is necessary. If the compatibility between organic carriers is poor, the viscosity of the mixture cannot be effectively reduced. Injection molding During the molding cooling process, a large amount of segregation of organic matter and the separation of the caking agent from the mold cannot obtain a molding body with uniform components.

[0011] The process of polymer material blending is actually a process of mutual diffusion between molecular chains, which is restricted by the force between molecular chains....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com