High-solid-content waterborne polyurethane dispersion solution based on amino carboxylate and amino sulfonate

A technology of sulfamate and aminocarboxylate, applied in the field of waterborne polyurethane dispersion, can solve the problems of difficult to prepare waterborne polyurethane with high solid content, weak stability of waterborne polyurethane, and decreased tensile strength, etc. content, good tensile strength, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

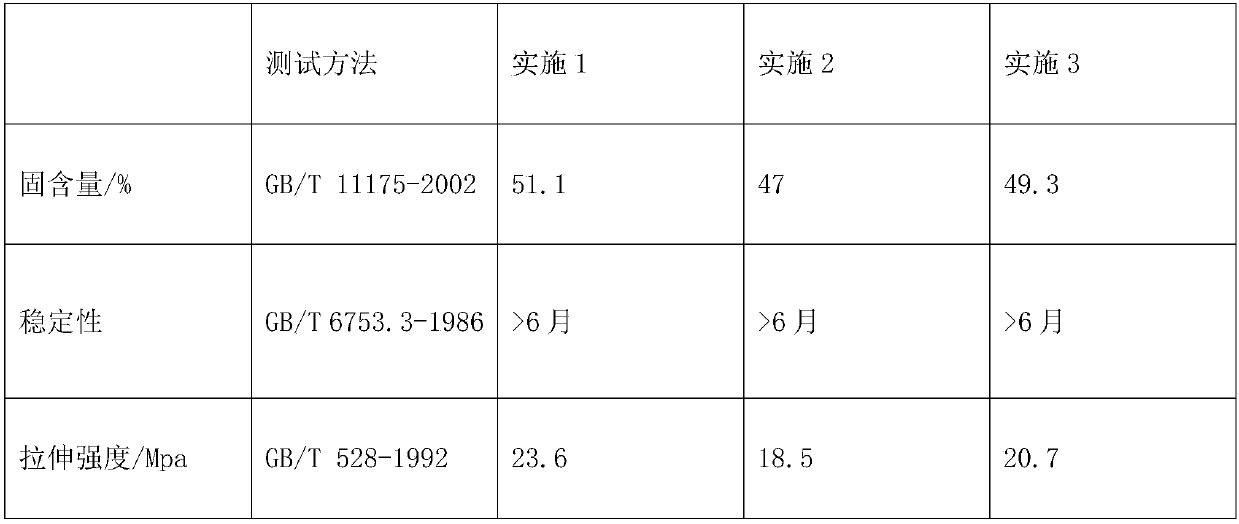

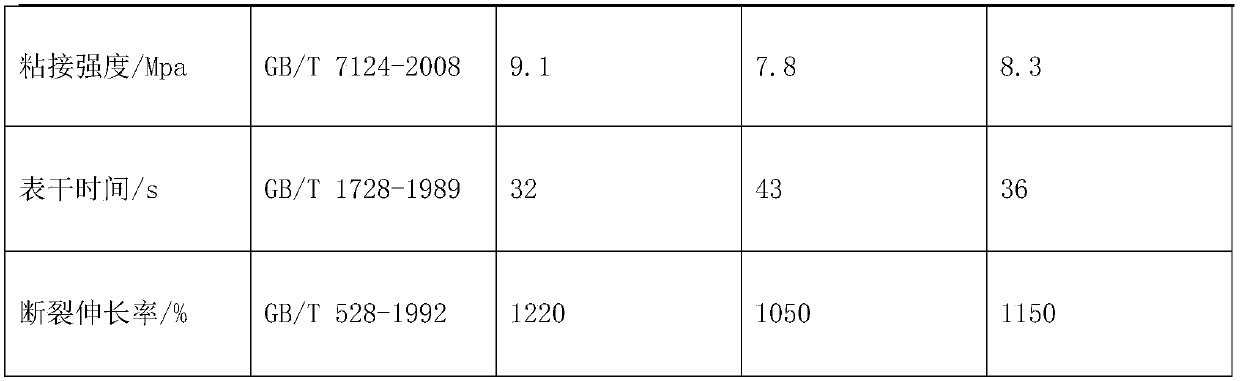

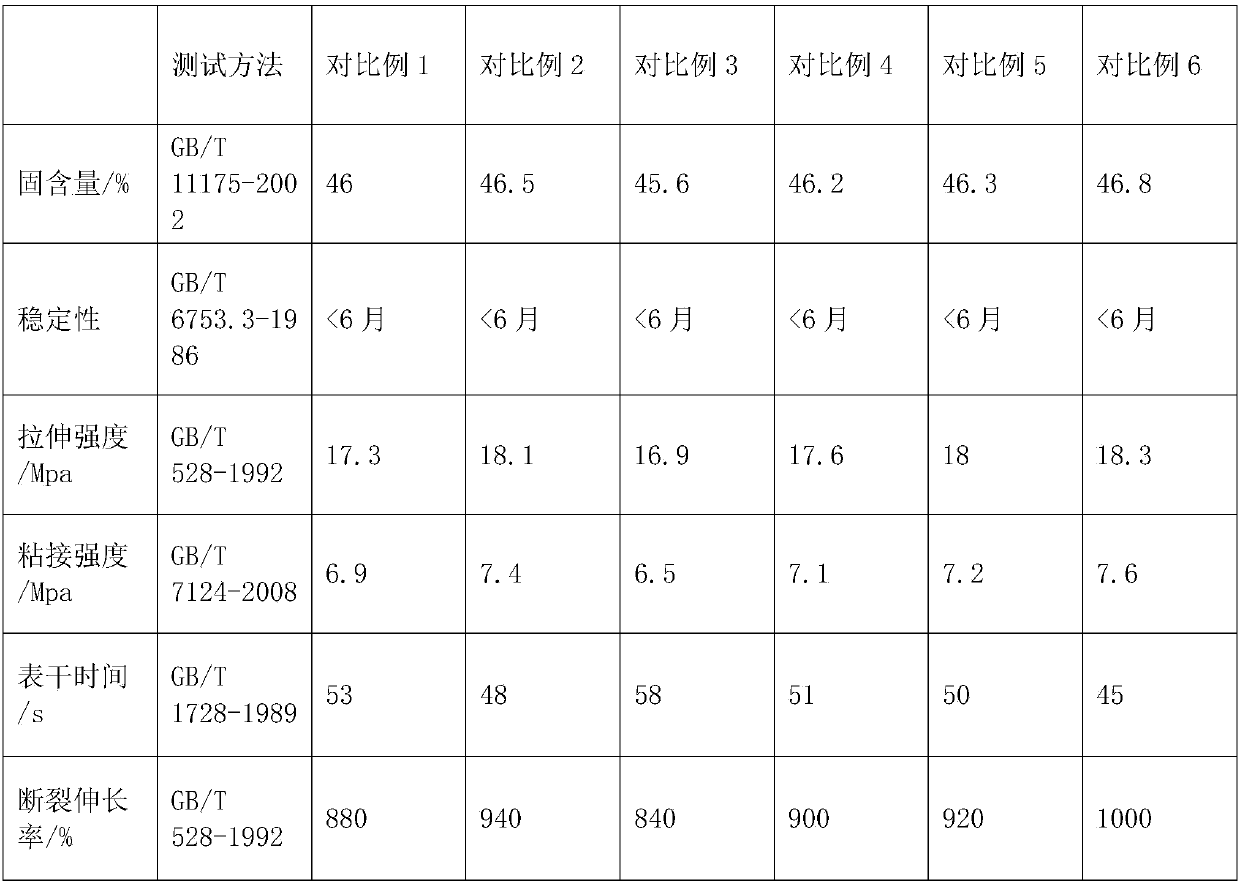

Examples

Embodiment 1

[0038] Embodiment 1: a kind of high solid content aqueous polyurethane dispersion liquid based on amino carboxylate and sulfamate simultaneously, comprises following composition by weight:

[0039] 45 parts deionized water

[0040] 18 parts polymer diol

[0041] 3.5 parts of small molecule polyol

[0042] 17 parts diisocyanate

[0043] 3 parts amino carboxylate hydrophilic chain extender

[0044] 3 parts sulfamate hydrophilic chain extender

[0045] 1.2 parts neutralizer

[0046] 0.3 part catalyst

[0047] 0.2 part lauryl phosphate

[0048] 1 part sodium 8-hydroxyquinoline-5-sulfonate

[0049] 0.5 parts of sodium N-tris(hydroxymethyl)methyl-3-aminopropanesulfonate

[0050] 0.2 part sodium 2-carbonylbutyrate

[0051] 0.2 parts beryllium acetate

[0052] 0.4 parts 1-methoxy-2-methyl-1-(trimethylsiloxy)propene

[0053] 0.2 parts of sodium diethyl oxaloacetate.

[0054] The small molecule polyhydric alcohol is a mixture of butanediol, 3-aminopropylsilanetriol and glycero...

Embodiment 2

[0067] Embodiment 2: a kind of high solid content aqueous polyurethane dispersion liquid based on amino carboxylate and sulfamate simultaneously, comprises following composition by weight:

[0068] 30 parts deionized water

[0069] 10 parts polymer diol

[0070] 2 parts small molecule polyol

[0071] 10 parts diisocyanate

[0072] 1 part Aminocarboxylate Hydrophilic Chain Extender

[0073] 1 part sulfamate hydrophilic chain extender

[0074] 0.5 part neutralizer

[0075] 0.1 part catalyst

[0076] 0.2 part lauryl phosphate

[0077] 1 part sodium 8-hydroxyquinoline-5-sulfonate

[0078] 0.5 parts of sodium N-tris(hydroxymethyl)methyl-3-aminopropanesulfonate

[0079] 0.2 part sodium 2-carbonylbutyrate

[0080] 0.2 parts beryllium acetate

[0081] 0.4 parts 1-methoxy-2-methyl-1-(trimethylsiloxy)propene

[0082] 0.2 parts of sodium diethyl oxaloacetate.

[0083] The small molecule polyhydric alcohol is a mixture of butanediol, 3-aminopropylsilanetriol and glycerol, and ...

experiment example 3

[0096] Experimental example 3: a kind of high solid content aqueous polyurethane dispersion liquid based on aminocarboxylate and aminosulfonate simultaneously, comprises following composition by weight:

[0097] 70 parts deionized water

[0098] 25 parts polymer diol

[0099] 5 parts small molecule polyol

[0100] 25 parts diisocyanate

[0101] 5 parts aminocarboxylate hydrophilic chain extender

[0102] 5 parts sulfamate hydrophilic chain extender

[0103] 2 parts neutralizer

[0104] 0.5 part catalyst

[0105] 0.2 part lauryl phosphate

[0106] 1 part sodium 8-hydroxyquinoline-5-sulfonate

[0107] 0.5 parts of sodium N-tris(hydroxymethyl)methyl-3-aminopropanesulfonate

[0108] 0.2 part sodium 2-carbonylbutyrate

[0109] 0.2 parts beryllium acetate

[0110] 0.4 parts 1-methoxy-2-methyl-1-(trimethylsiloxy)propene

[0111] 0.2 parts of sodium diethyl oxaloacetate.

[0112] The small molecule polyhydric alcohol is a mixture of butanediol, 3-aminopropylsilanetriol and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com