Polymethano-poly(methyl)acrylic ester two-block copolymer and preparation method thereof

A technology of block copolymers and acrylates, which is applied in the field of polymethylene/polyacrylate diblock copolymers and its preparation, can solve the problems of preparing macromolecular initiators, block copolymer research and Application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 32

[0040] The specimens in Example 32 were prepared using a micro-injection molding machine (ISO527-2-A5a tensile test mold).

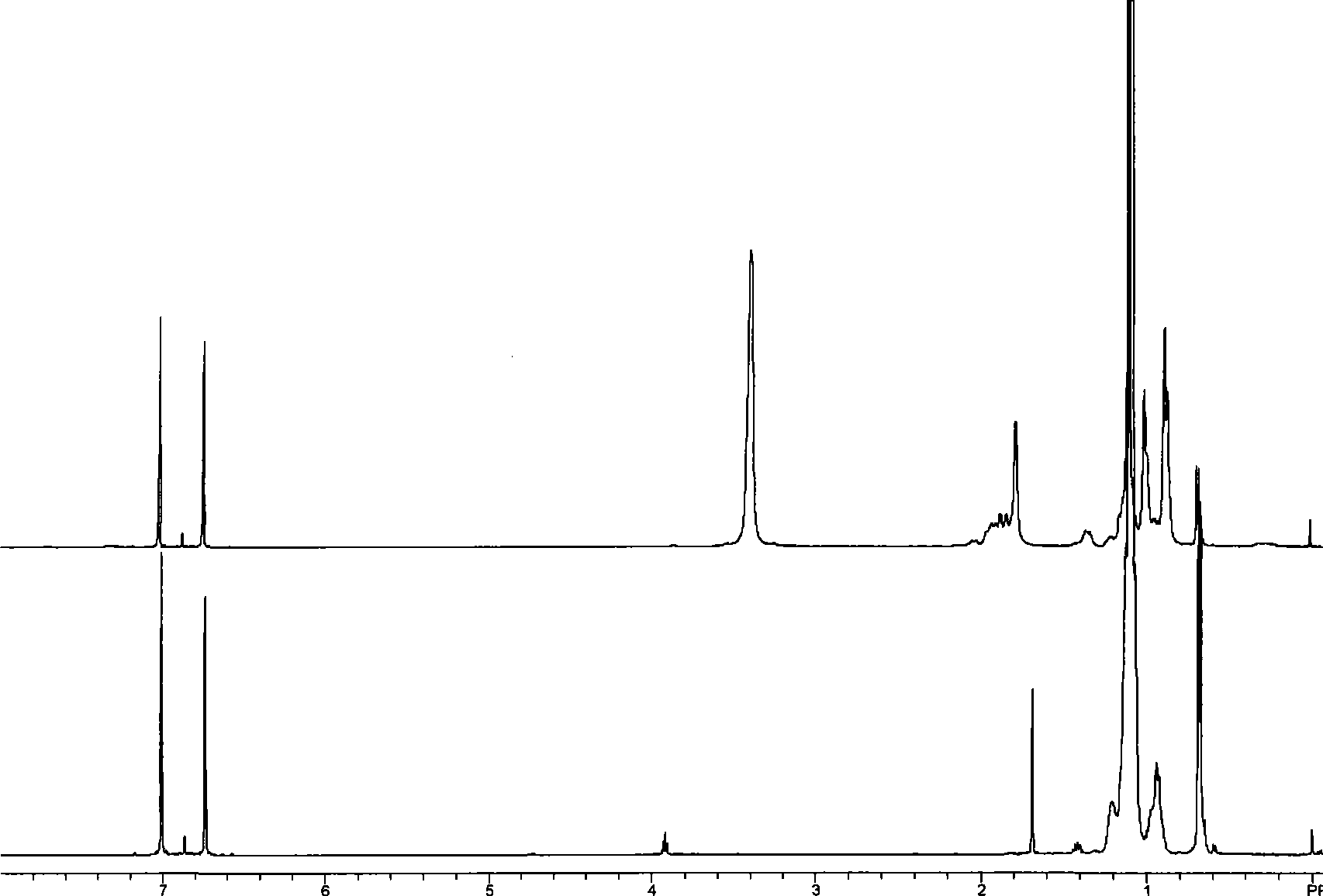

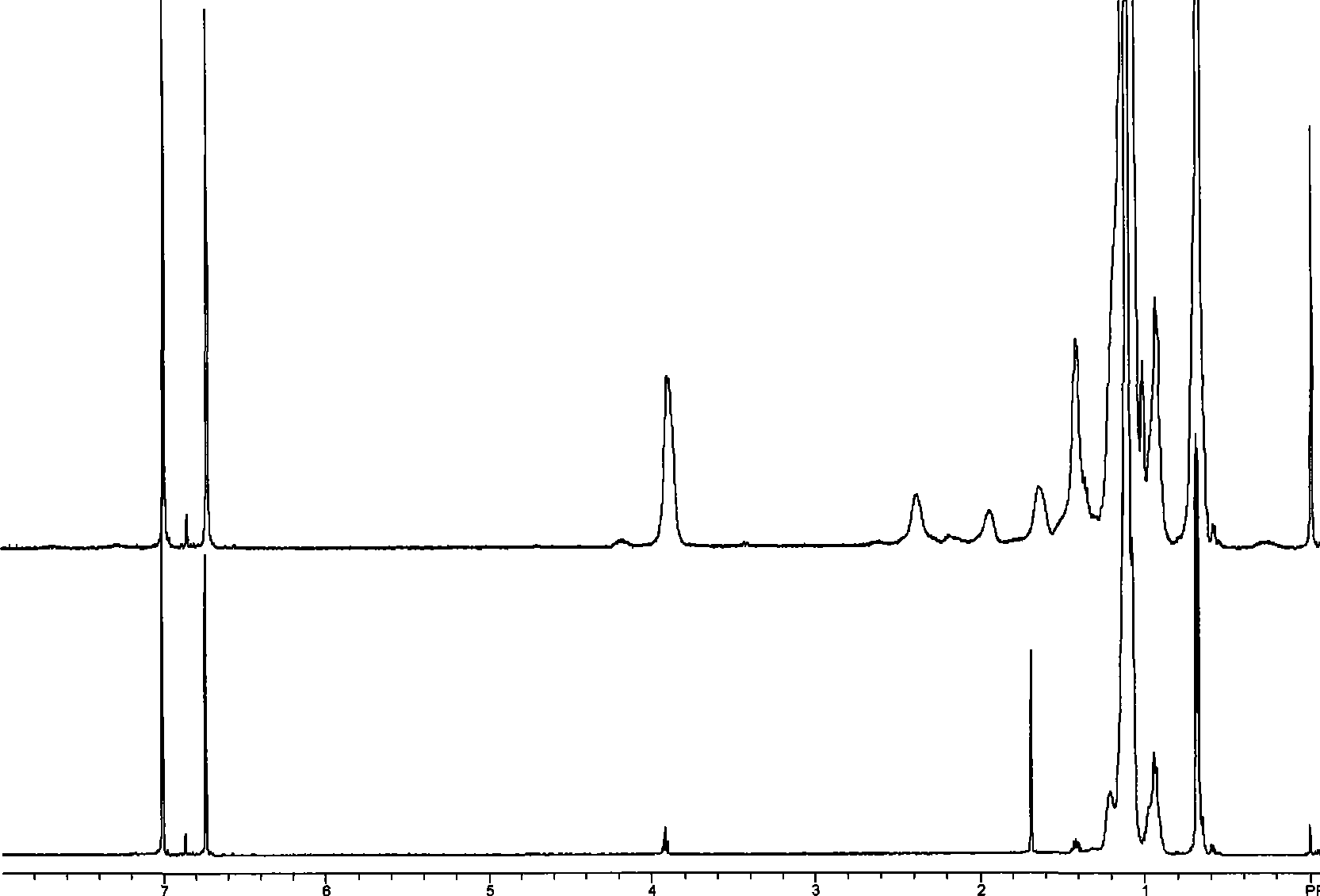

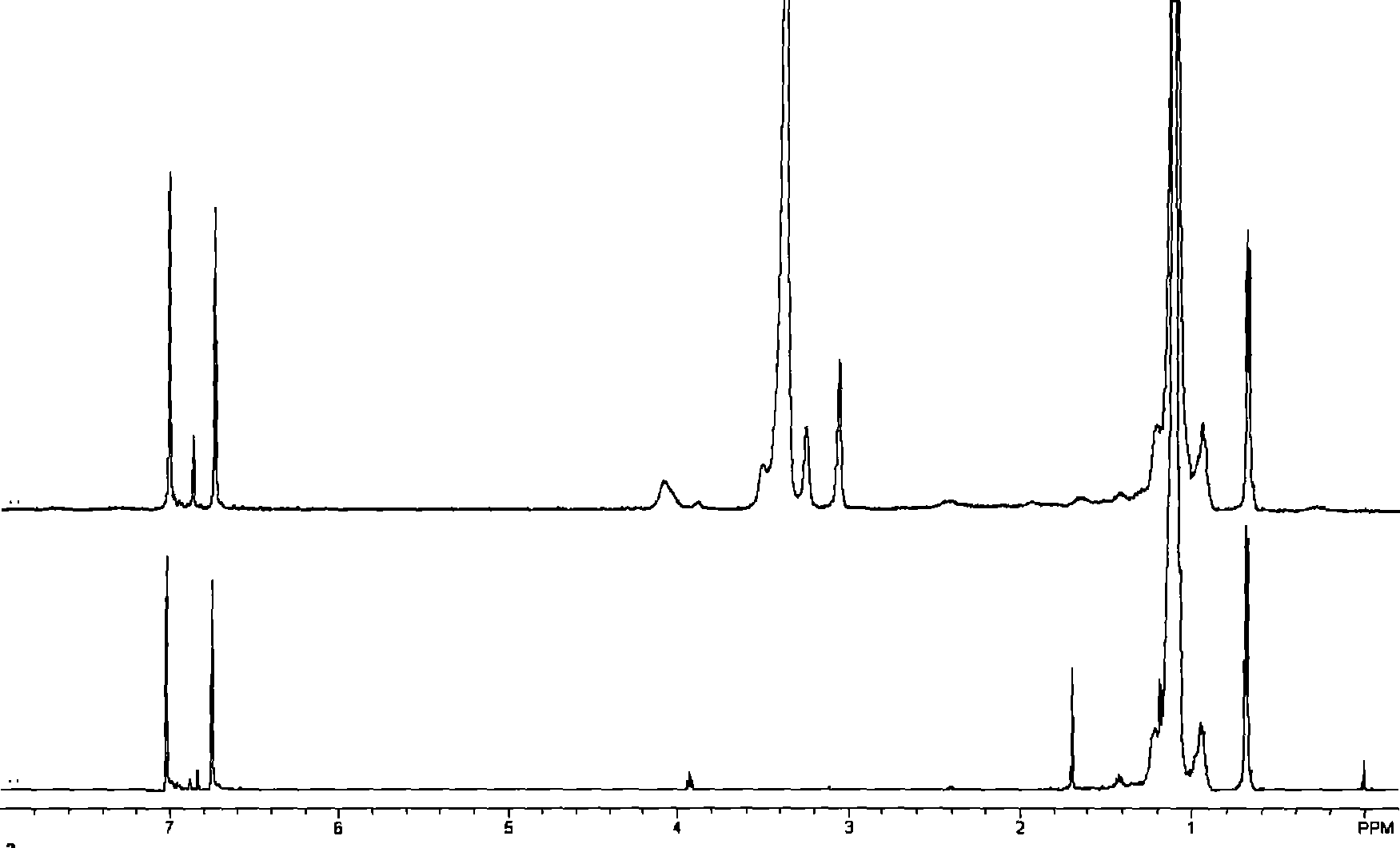

[0041] The bromine content of the polymer is based on 1 H-NMR spectrum calculated.

Embodiment 1

[0043] The preparation of polymethylene / poly(meth)acrylate block copolymer with controllable structure of the present invention:

[0044] In a dry 10mL round bottom flask A with a magnetic stirrer, add 0.10g (0.054 mmol Br) of macromolecular initiator MI-01 (M n = 1856, PDI = 1.23, n = 120, bromine content = 540 μmol / g polymer, 1 H NMR (500MHz, δ ppm): 3.92(t, 2H), 1.69(s, 6H), 1.42(t, 2H), 1.10(m, 240H), 0.67(s, 12H), ), after 30min of vacuum , filled with nitrogen. In another 10mL dry round-bottomed flask B with a magnetic stir bar, add CuBr 7.7mg (0.054mmol), PMDETA (N,N,N',N',N"-pentamethyldi Ethylene triamine) 22.5 L 0.108mmol), MMA (methyl methacrylate) 0.58mL (5.4mmol, after vacuum distillation) and toluene 2.5mL (after metal sodium reflux treatment), after stirring for 30min, under nitrogen protection The above mixture was transferred to the round bottom flask A with a dry double-ended needle tube, and the polymerization reaction was carried out at 90 ° C for 6 h. A...

Embodiment 2~ Embodiment 7

[0046] The preparation of polymethylene / poly(meth)acrylate diblock copolymer with controllable structure of the present invention:

[0047] Operation is basically the same as embodiment 1. The difference is that in the ATRP polymerization reaction, the types and amounts of catalysts and ligands, reaction solvents and amounts thereof, reaction temperature and reaction time are not completely the same as in Example 1. Structure-controllable polymethylene / poly(meth)acrylate diblock copolymers P-02 (n=120, m=20), P-03 (n=120, m=24), P-03 (n=120, m=24), P-04(n=120, m=50), P-05(n=120, m=92), P-06(n=120, m=66) and P-07(n=120, m=96 ).

[0048] The specific experimental conditions and polymer characterization data are shown in Table 1:

[0049] In the products of Examples 2-7, R 1 and R 2 Both CH 3 .

[0050] Table 1

[0051]

[0052] Note: b-Py=2,2'-bipyridine or its alkyl derivatives, PMDETA (N,N,N',N',N"-pentamethyldivinyltriamine)

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com