Hydrocarbon oil conversion method

A hydrocarbon oil and catalyst technology, applied in chemical instruments and methods, cracking, inorganic chemistry, etc., can solve the problem of low hydrogen production rate and achieve the effect of increasing hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

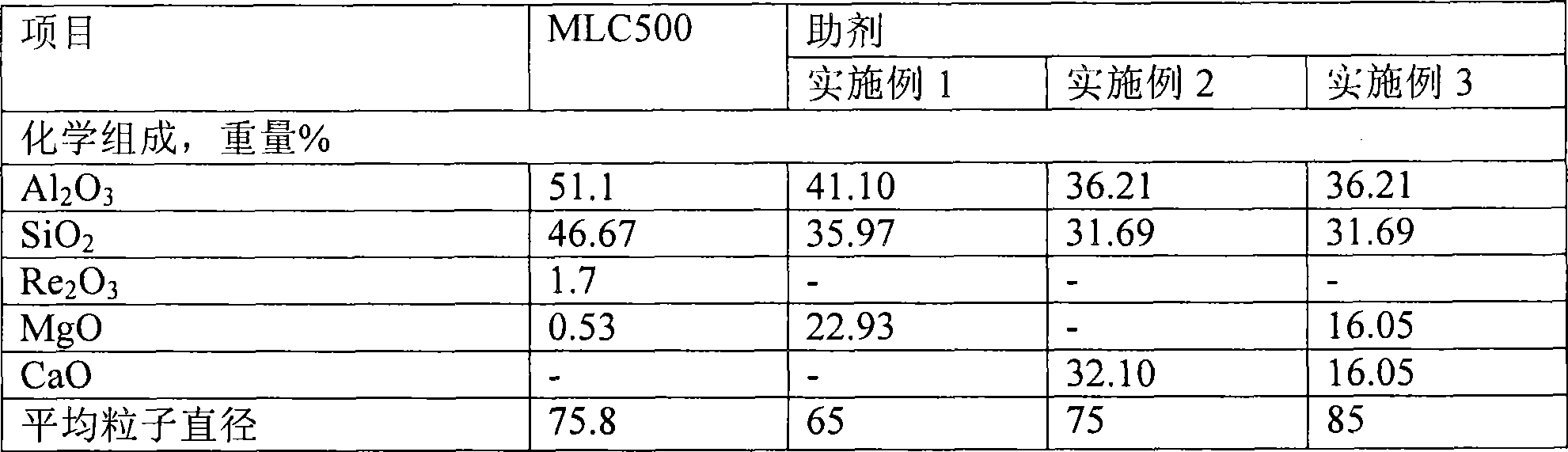

Embodiment 1

[0040] This example is used to illustrate the hydrocarbon oil conversion method provided by the present invention.

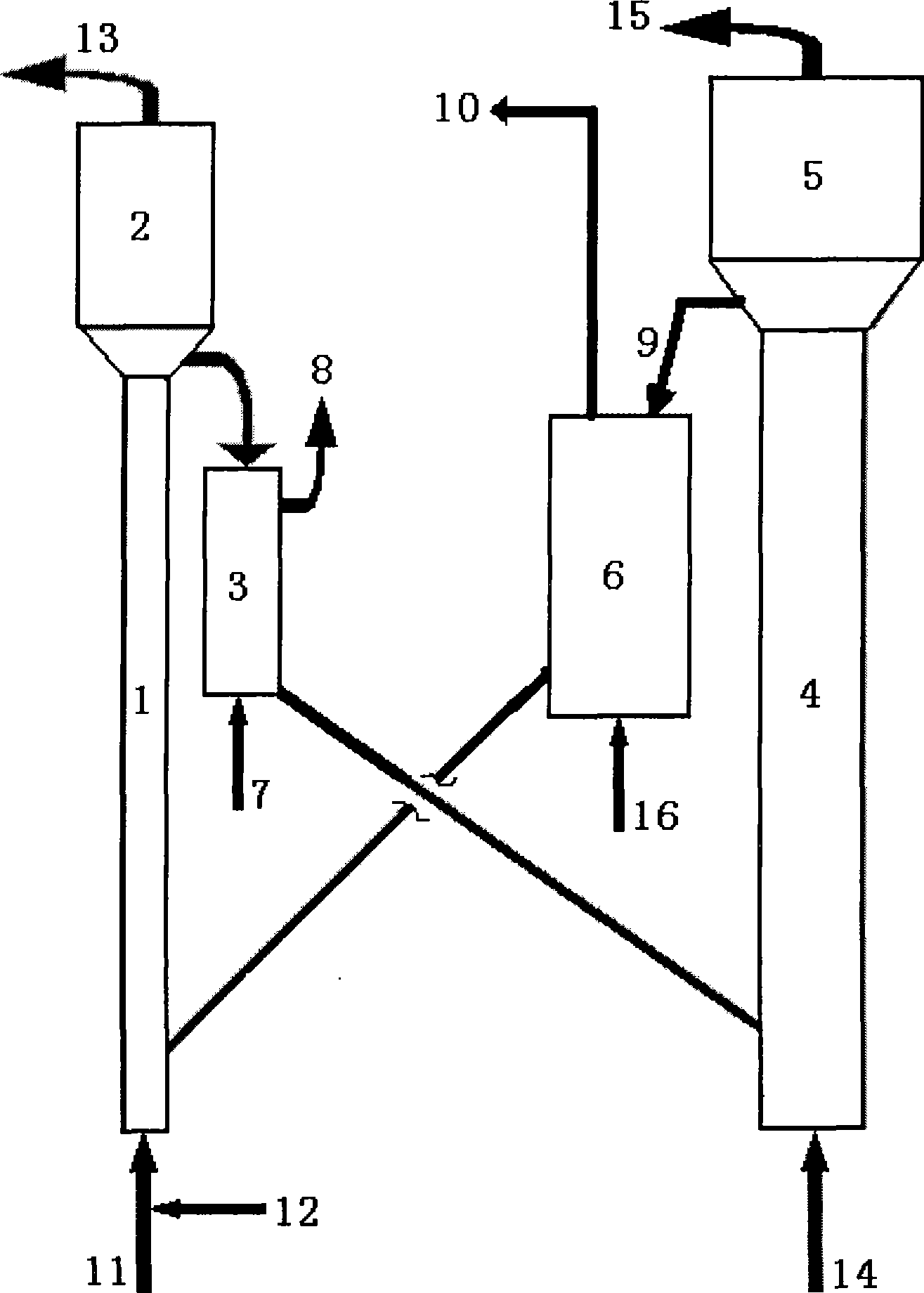

[0041] Such as figure 1 As shown, the regenerated catalyst completely regenerated in the second regenerator 6 is sent to the bottom of the riser reactor 1, hydrocarbon oil 11 and steam 12 are added from the bottom of the riser reactor 1, and the catalyst is contacted with the hydrocarbon oil to obtain Reaction products and spent catalysts. The reaction conditions in the riser reactor 1 include: the reaction temperature is 480°C, the reaction time is 3 seconds, the weight ratio of catalyst to hydrocarbon oil is 5:1, the reaction pressure is 200 kPa, the weight ratio of water vapor to hydrocarbon oil is It is 0.08:1.

[0042] The reaction product 13 and the raw catalyst are separated by the settler 2, and then the raw catalyst is stripped by the stripper 3 and sent to the first regenerator 4, and the oxygen-containing gas 14 is added from the bottom of the first...

Embodiment 2

[0048] This example is used to illustrate the hydrocarbon oil conversion method provided by the present invention.

[0049] The hydrocarbon oil is converted according to the same method as in Example 1. The difference is that the reaction conditions in the first regenerator include: the reaction temperature is 600 ° C, the reaction bed is a fluidized bed, and the empty bed gas velocity is 1 m / seconds, the reaction time is 10 seconds, and the bed pressure is 200 kPa; the oxygen-containing gas is a mixture of oxygen and water vapor, and the oxygen is 15% by volume of the total amount of the mixture; 8% by weight of catalyst. The composition of the synthesis gas is shown in Table 3.

Embodiment 3

[0054] This example is used to illustrate the hydrocarbon oil conversion method provided by the present invention.

[0055] The hydrocarbon oil is converted according to the same method as in Example 1. The difference is that the reaction conditions in the first regenerator include: the reaction temperature is 700 ° C, the reaction bed is a fluidized bed, and the empty bed gas velocity is 1.2 m / seconds, the reaction time is 15 seconds, and the bed pressure is 300 kPa; the oxygen-containing gas is a mixture of oxygen and water vapor, and the oxygen is 25% by volume of the total amount of the mixture; 12% by weight of catalyst. The composition of the synthesis gas is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com