LED illumination lamp

A technology of LED lighting and LED light source, applied in lighting devices, lighting and heating equipment, components of lighting devices, etc., can solve the problem of LED lighting lamp housing temperature rise, lengthening LED lighting lighting distance, and the heat dissipation effect is not too much. Ideal and other problems, to achieve the effect of improving the light distance and light intensity, good heat dissipation effect, and small power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

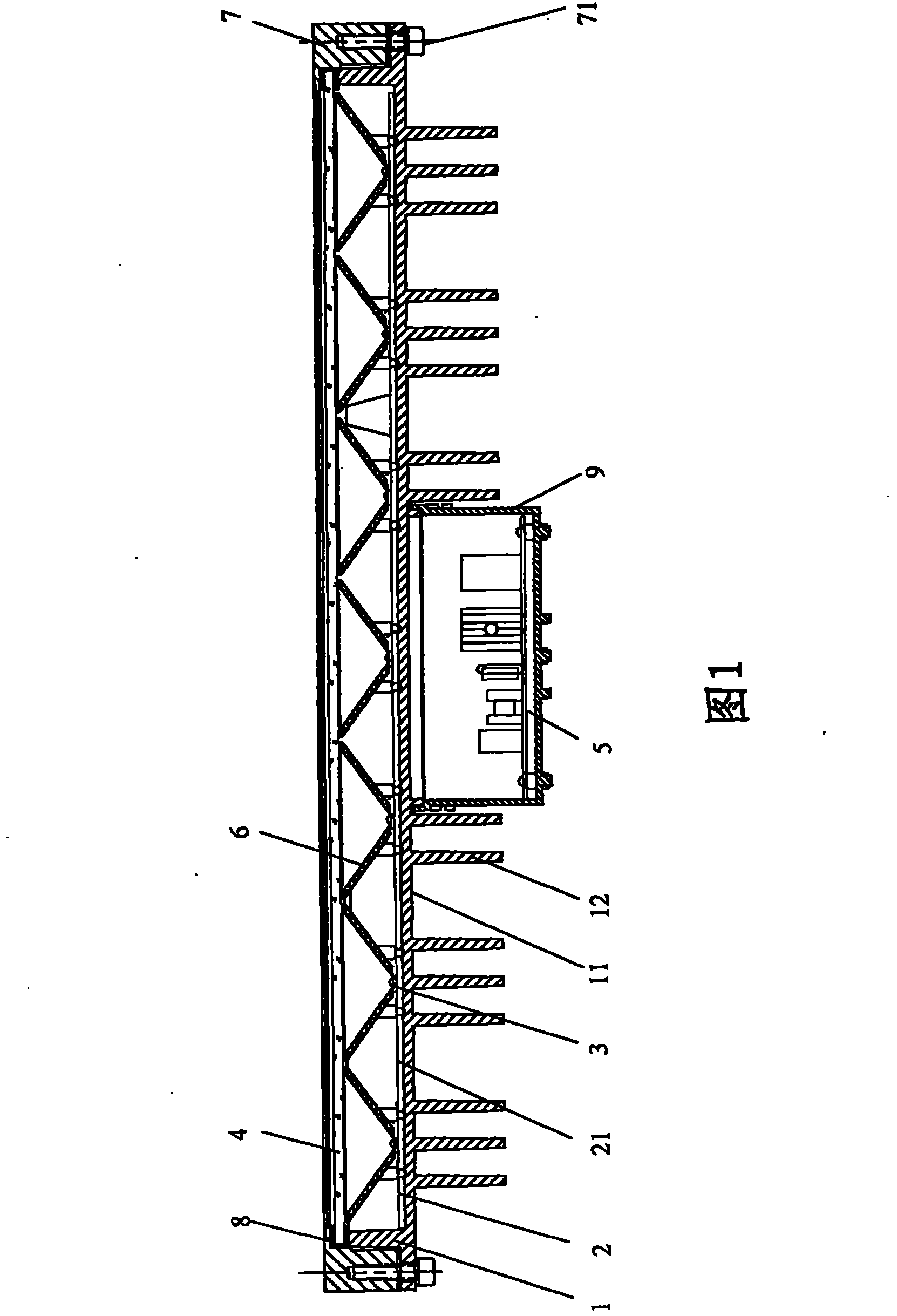

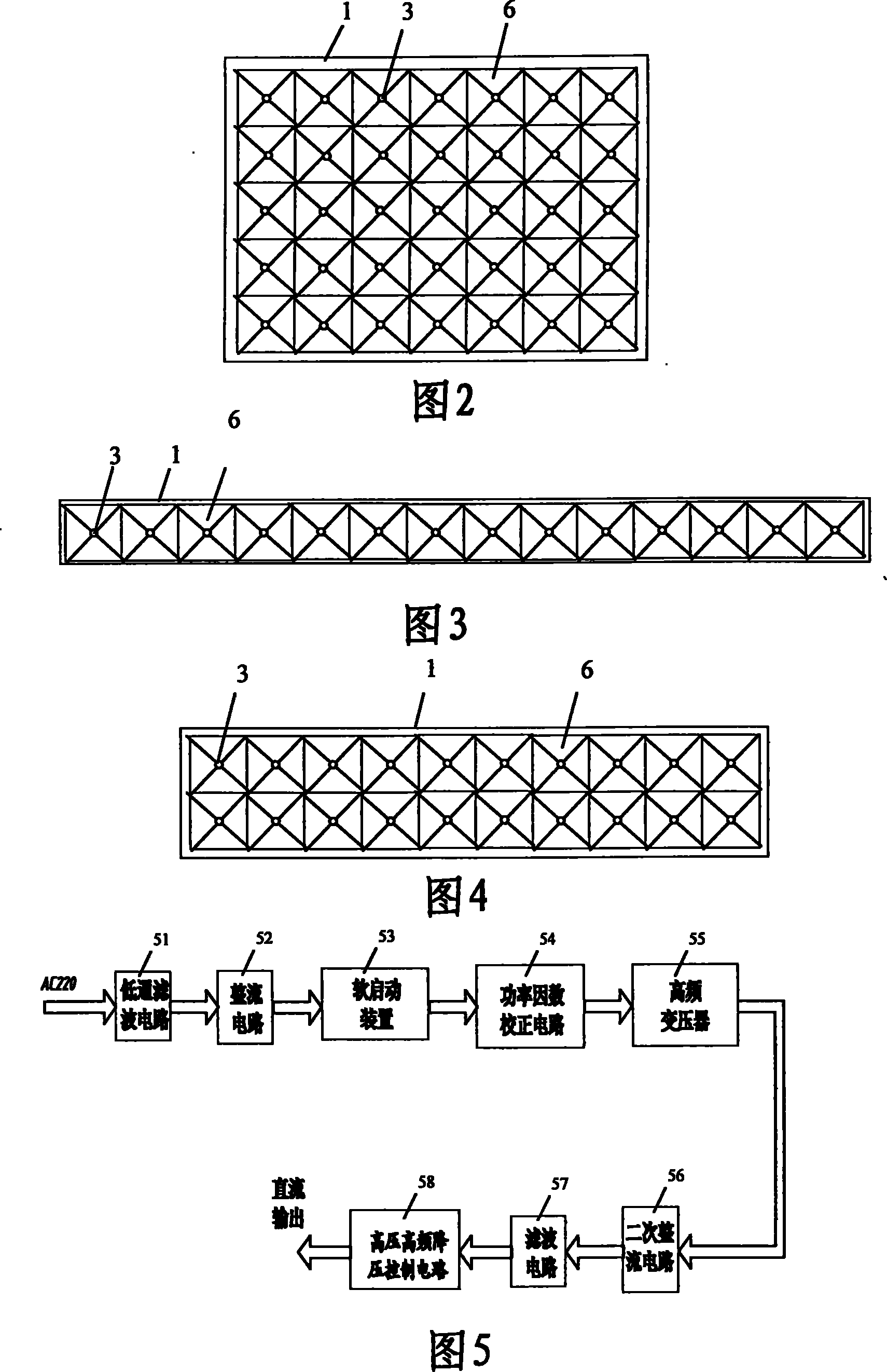

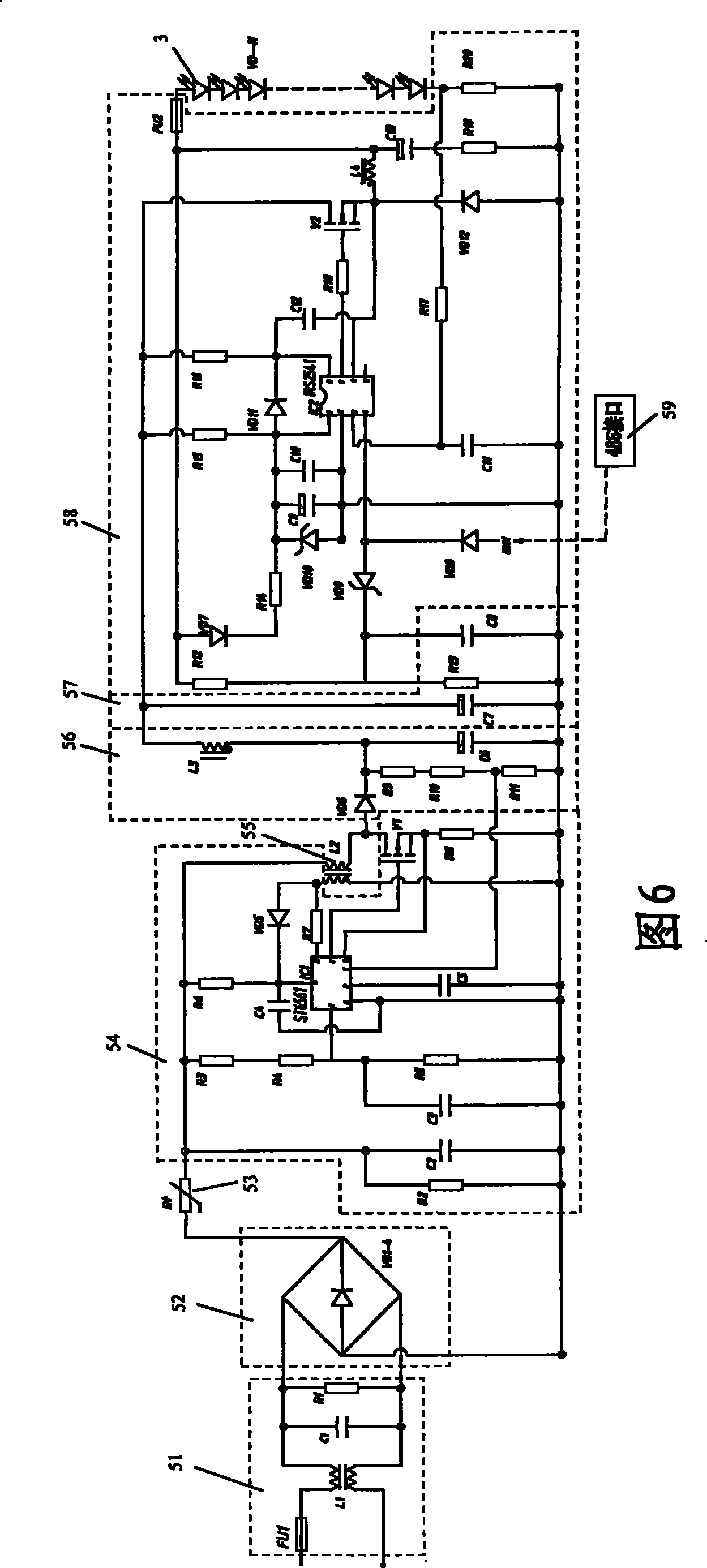

[0025] Such as figure 1 As shown, the LED lighting lamp of the present invention includes a housing 1 , a circuit board 2 , a plurality of LED light sources 3 , a transparent cover 4 , an AC / DC constant current drive power supply 5 , and a plurality of reflector cups 6 .

[0026] Wherein, the shell 1 is formed by one-time die-casting of aluminum alloy, and the back shell 11 of the shell 1 has a heat sink 12 . The shell 1 is made of aluminum alloy, because aluminum alloy is an excellent heat conductor, which can quickly conduct heat generated in the shell 1, and a heat sink 12 is set on the back shell plate 11 of the shell 1, which not only increases the heat dissipation of the back of the shell. The heat dissipation surface area also causes a temperature difference between the inner and outer distances, so that the heat in the shell 1 can be dissipated more quickly.

[0027] The circuit substrate 2 adopts an aluminum substrate 21 , and the aluminum substrate 21 is directly at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com