Core-shell particle composition, method and article

一种颗粒、混合物的技术,应用在核-壳颗粒组合物、及制品领域,能够解决产品成本增加、含硅石橡胶组合物性能下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

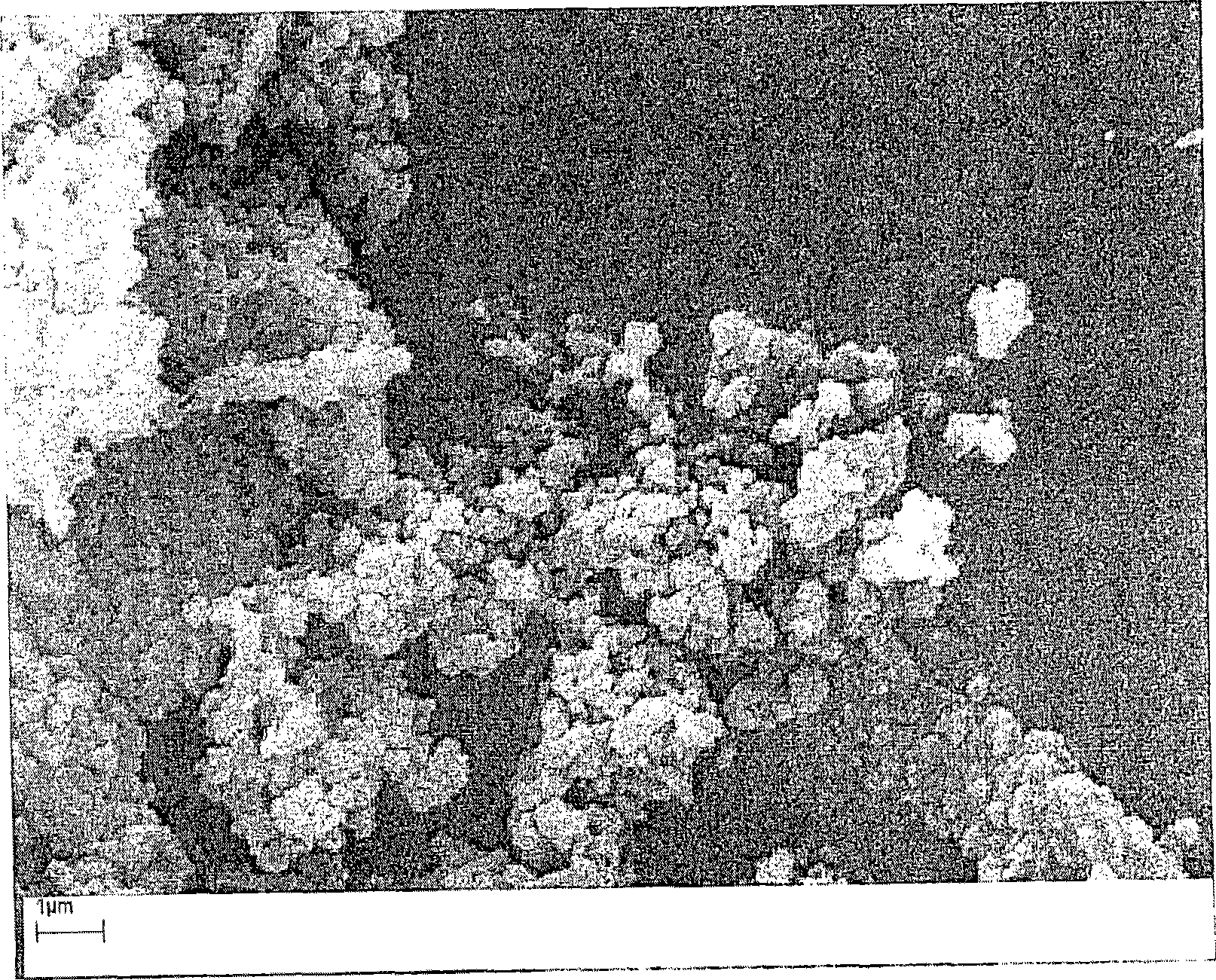

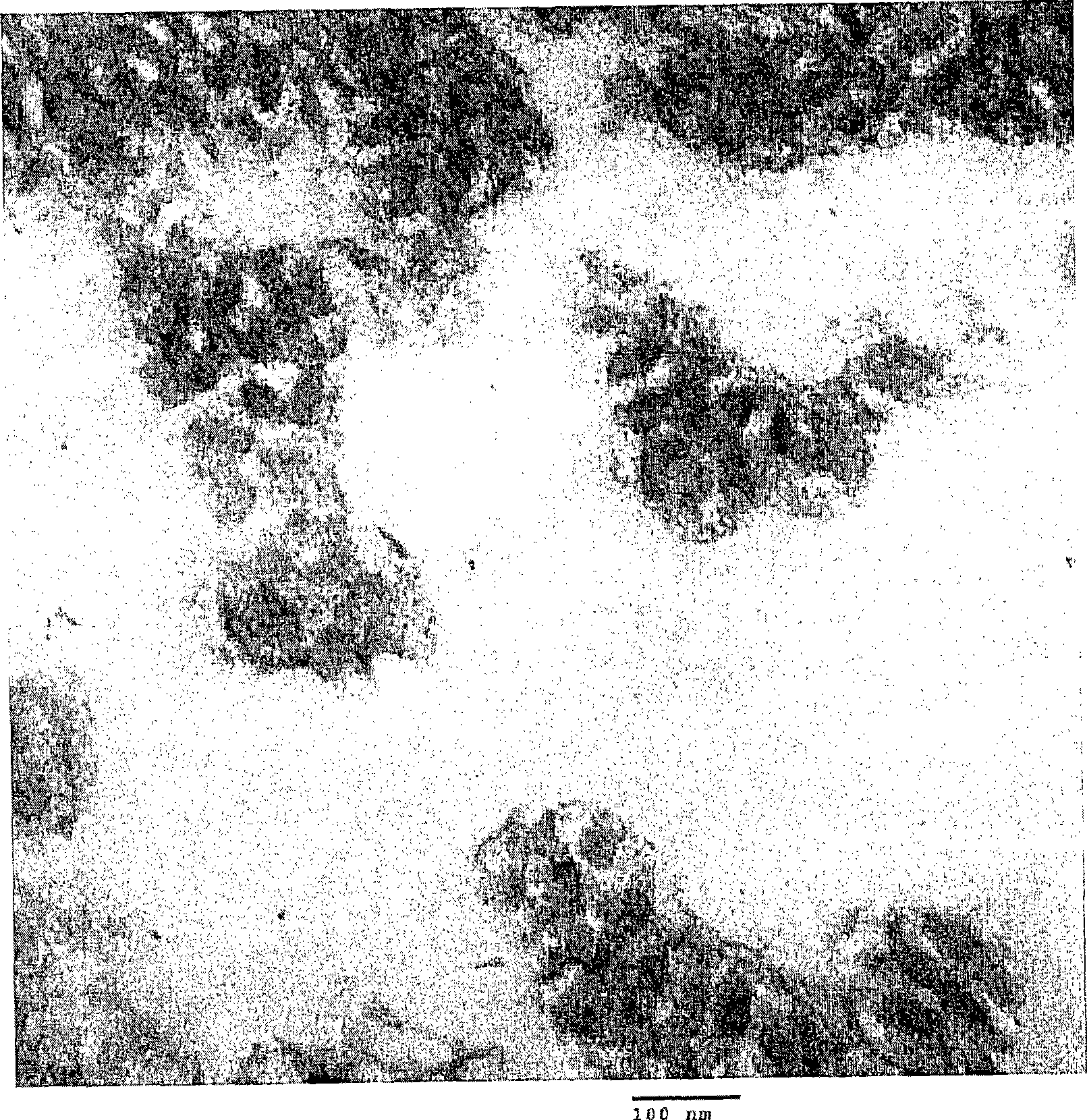

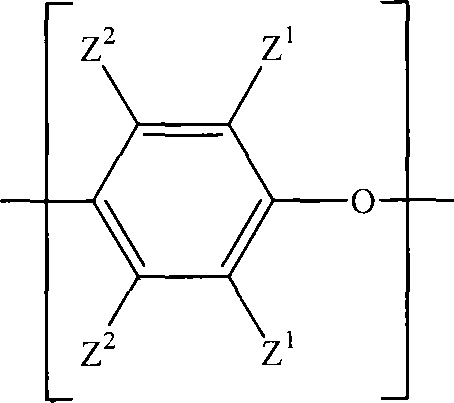

[0062] At 40° C., 70 grams of poly(2,6-dimethyl-1,4-phenylene ether) (PPE; available from GE Plastics and having an intrinsic viscosity of about 0.31 dl / g) and 55% 30 g of a mixture of polystyrene-polyisoprene diblock copolymer and 45% by weight polystyrene-polyisoprene-polystyrene triblock copolymer by weight (SI+SIS; D1113P, obtained from Kraton Polymers and having a polystyrene content of 16% by weight and a polyisoprene content of 84% by weight) was added to 3.3 liters (L) of tetrahydrofuran to make a 3% polymer solution. Stir the PPE / (SI+SIS) solution until homogeneous.

[0063] Antisolvent solution: Mix 6.2 L of methyl ethyl ketone (MEK) and 4.1 L of methanol (MeOH) to make 10.3 L of antisolvent solution, where the volume ratio of MEK to MeOH is 1.5:1.0 and the total volume of the antisolvent solution is 3 times the total volume of the PPE / (SI+SIS) solution.

[0064] Charging the system: Allow the poly(arylene ether) solution to come to room temperature, then immedia...

Embodiment 2

[0069] Embodiment 2, comparative example 1

[0070] These examples illustrate the effectiveness of the particles of the present invention in reducing heat build-up (HBU) in rubber compositions. According to ASTM D 3182-89, vulcanized rubber samples of the two compositions were prepared in the same manner using the formulations listed in Table 1. All contents in the table are listed in parts per 100 parts by weight of rubber (phr). The filler content per 100 parts by weight of rubber was kept constant between the two compositions. Example 2 Composition with filler consisting of carbon black, poly(arylene ether) component of core-shell particles, and polystyrene-polyisoprene-polystyrene triblock copolymer of core-shell particles composition of the polystyrene component (the polyisoprene component of the core-shell particles is counted as part of the rubber). The weight basis of Example 2 rubber consists of the sum of the weights of natural rubber and the polyisoprene component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com