Paste composition for aluminum brazing

一种组合物、铝钎焊的技术,应用在焊接介质、焊接设备、焊接/切割介质/材料等方向,能够解决热分解性能差、产生黑色残渣物等问题,达到钎焊性优异、简便涂布作业的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

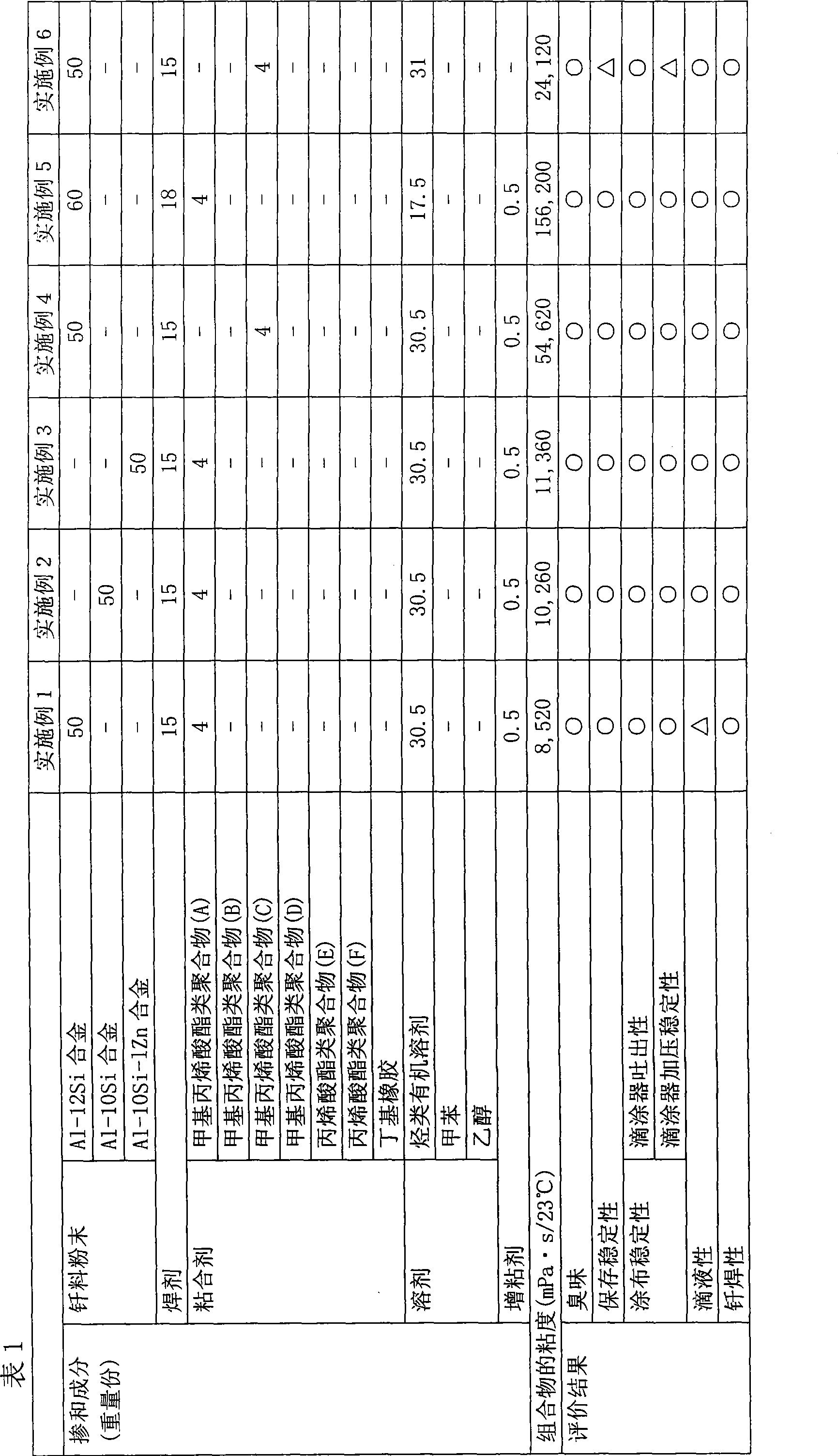

[0061] Examples 1 to 3 are examples in which the component (a), that is, the metal powder for brazing (brazing filler metal powder) is different in type, but the other components and compositions are the same. Example 4 is an example in which the type of methacrylate polymer which is the component (c) is different from Example 1. Example 5 is an example in which the overall composition is different from Examples 1-4. That is, as the above-mentioned component (c) (binder), in Examples 1 to 3 and 5, a homopolymer of 2-ethylhexyl methacrylate (methacrylate polymer (A)) was used, In Examples 4 and 6, a copolymer of 2-ethylhexyl methacrylate and 2-hydroxyethyl methacrylate (methacrylate-based copolymer (C)) was used.

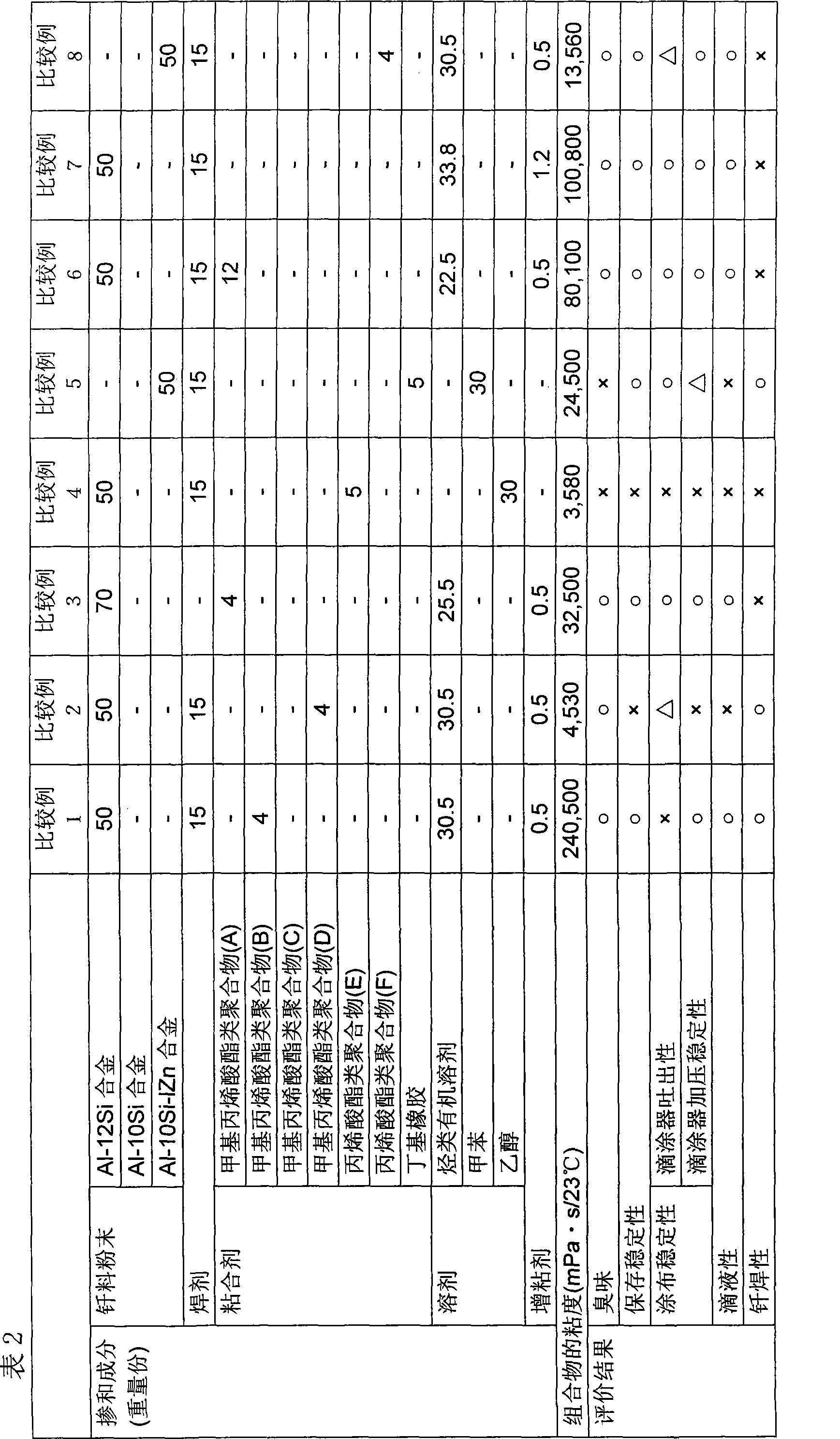

[0062]On the other hand, among Comparative Examples 1 to 8 below, Comparative Example 1 is an example in which the viscosity of the solder paste composition exceeds the upper limit of the suitable range of the present invention. Comparative Example 2 is an example ...

Embodiment 1~6 and comparative example 1~8

[0065] Each compounding component was mixed with the composition shown in Table 1 and Table 2, and the solder paste composition for aluminum brazing which has the viscosity (23 degreeC) shown in Table 1 and Table 2 was manufactured. Then, the viscosities at 23° C. were measured using a screw pump viscometer (“PCU-205” manufactured by Malcolm Co., Ltd.) at a stirring rate of 10 rpm, and the following (i) to (vi) were performed for each of the obtained solder paste compositions. various evaluation tests. The results are shown in Tables 1 and 2 together.

[0066] In addition, the details of each compounding component shown in Table 1 and Table 2 are as follows.

[0067]

[0068] ・Al-12Si alloy: average particle size = 52μm

[0069] ・Al-10Si alloy: average particle size = 55 μm

[0070] ・Al-10Si alloy-1Zn alloy: average particle size = 49 μm

[0071]

[0072] Fluoride-based flux (potassium fluoroaluminate): "Nocoloc Flux 100" manufactured by Solvay Co., Ltd.

[0073]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com