Dry-mixed mortar station

A dry-mixed mortar and dry sand technology, applied in the direction of mixing operation control, mixing operation control device, mixing plant, etc., can solve the problems of single ready-mixed mortar, difficult mechanical construction, unstable mortar quality, etc., and achieve construction performance and The effect of superior quality, efficient production capacity, and excellent measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

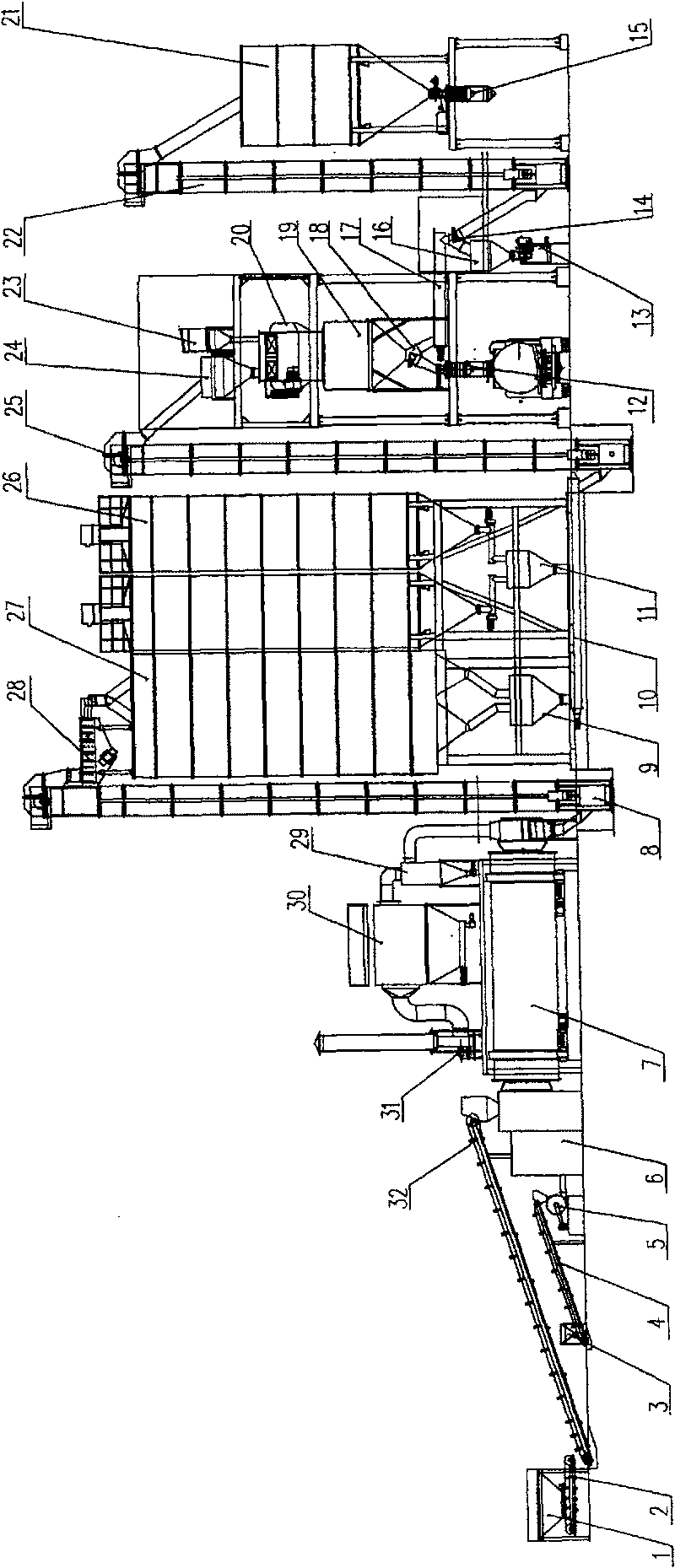

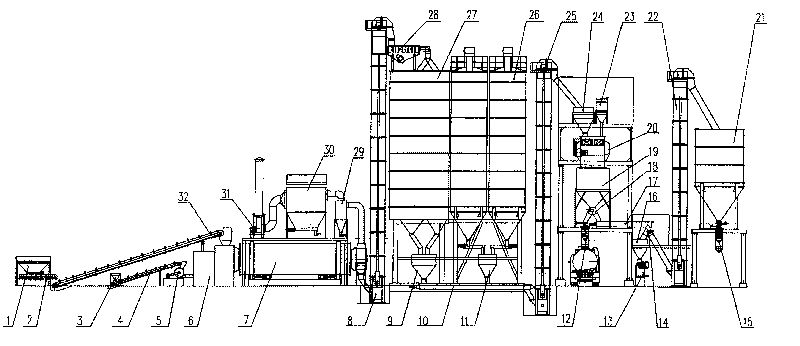

[0016] In the figure, the present invention consists of a sand conveying system, a drying system, a dust removal system, a dry sand lifting and screening and storage system, a powder storage system, a mixture metering and conveying system, a stirring system, and finished product storage, conveying and packaging. system etc. The sand conveying system is mainly composed of a sand bin 1, a frequency conversion control conveying belt conveyor 2, and an upper sand belt conveyor 32. The sand bin 1 is supported on the foundation by a steel structure frame, the upper part is rectangular, and the lower part adopts a conical surface structure, and the conical mouth is connected with the frequency conversion control conveyor belt conveyor 2; 2 and the feed port of the three cylinder dryer 7 are connected. The sand material in the sand bin is loaded by a loader, and the frequency conversion control conveyor belt conveyor 2 is fully enclosed, and is used for quantitative feeding to the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com