Polymerizable composition, resin using the same, optical component and compound

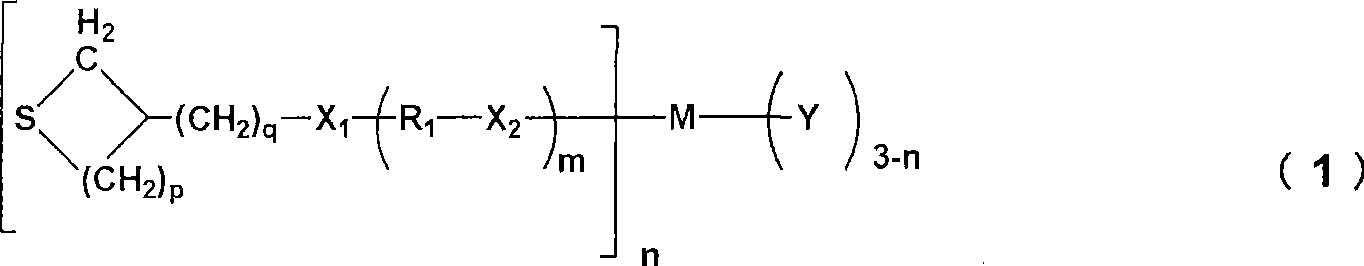

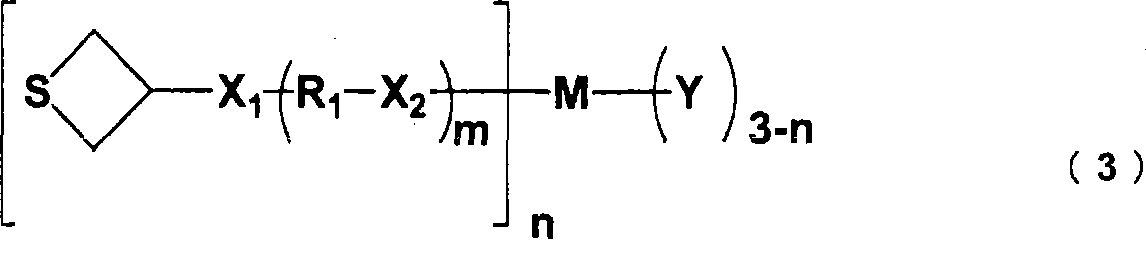

一种聚合性组合物、光学部件的技术,应用在光学元件、周期表第5/15族元素的化合物、光学等方向,能够解决树脂安全性存在问题、透明性树脂机械物性问题等问题,达到良好机械强度、高透明性、良好耐热性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0145] Hereinafter, the present invention will be more specifically described based on production examples and examples, but the present invention is not limited to these examples.

[0146]

[0147] [Reference Manufacturing Example 1]

[0148] According to the method described in SYNTHETIC COMMUNICATION magazine, 2003, pages 595-600, 2,3-epithiol-1-propanol was synthesized. That is, 152 g of thiourea, 74 g of glycidol, 18.7 g of lithium tetrafluoroborate, and 500 g of acetonitrile were charged into a reactor equipped with a stirring device and a thermometer. The reaction was carried out with stirring under reflux for 0.5 hours. Then, 300 g of water was added and extracted twice with 500 g of chloroform. The obtained organic layer was dried over anhydrous sodium sulfate, and the solvent was distilled off with an evaporator. Purify with a silica gel column to obtain 72 g of 2,3-epithio-1-propanol (separation yield 80%).

Embodiment A1

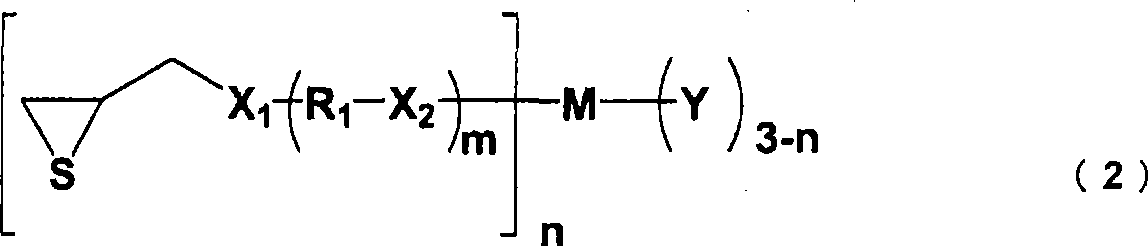

[0150] [Manufacture of the compound represented by the formula (2-1) of the present invention]

[0151] Add 42.6g (0.473 moles) of 2,3-epithiol-1-propanol into 500g of dry tetrahydrofuran, cool to -30°C, add 50.1g (0.495 moles) of dry triethylamine at the same temperature, and stir 5 minutes. Next, 90 ml of a tetrahydrofuran solution of thiophosphoryl chloride (corresponding to 0.150 mol of thiophosphoryl chloride) was added dropwise over 2 hours at -30°C. After completion of the dropwise addition, the temperature was raised to -20°C, and the mixture was further stirred at this temperature for 4 hours. After filtering the reaction mixture to remove the salt, 600ml of toluene and 600ml of water were added to separate into an organic layer and an aqueous layer. The organic layer was washed with 500 ml of 1% NaHCO 3 The aqueous solution and 500 ml of pure water were washed twice, respectively, and dried over anhydrous magnesium sulfate. Dichloromethane and toluene were distil...

Embodiment A2

[0154] [Manufacture of the compound represented by the formula (2-2) of the present invention]

[0155] Except using 2,3-epithiol-1-propanethiol instead of 2,3-epithiol in embodiment A1 Except for 1-propanol, the same operation was carried out to obtain 30.8 g (yield 54%) of tris(β-epithiopropyl)phosphorothioate (V) of the following formula (2-2). 1H-NMR data are given below (solvent: CDCl 3 , internal standard substance: TMS); δ 2.35(3H), δ 2.65(3H), δ 3.10(3H), δ 3.25(3H), δ 3.45(3H).

[0156]

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com