Method for preparing nano silver colloidal sol for preventing color change

A technology of nano-silver sol and anti-color change, which is applied in botany equipment and methods, chemicals for biological control, animal repellent, etc., can solve problems such as color change, and achieve simple preparation method and good anti-color change. Excellent effect of discoloration ability and antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 The preparation method of this anti-discoloration nano-silver sol comprises the following steps:

[0026] Add 2.5g of polyvinyl alcohol and 0.95g of silver nitrate solid into 2.5L of deionized water to dissolve, prepare an oxidation solution and pour it into a reaction kettle, heat the temperature of the oxidation solution to 110°C, and stir at a speed of 50rpm;

[0027] Add 500g of ethanol to 1.8L of water and dissolve to prepare a reducing solution;

[0028] Add the reduction solution dropwise to the oxidation solution at a rate of 60 drops / min with a single injection flow controller;

[0029] After the reducing solution was added dropwise, the stirring was continued for 1 hour to obtain a colorless and transparent nano-silver colloid with an average particle diameter of 20 nm.

[0030] First, according to the Volhard method, the silver content in the nano-silver colloid is 125mg / kg;

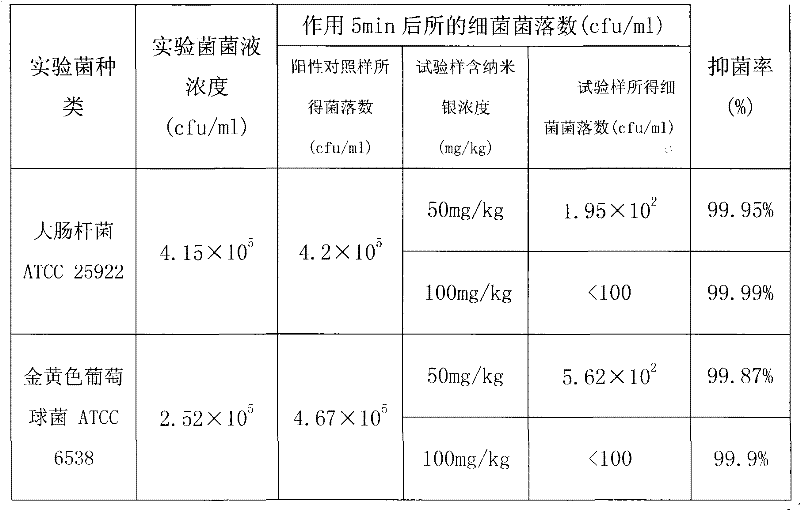

[0031] Thereafter, according to the GB / 15979-2002 standard, the anti...

Embodiment 2

[0043] Embodiment 2 The preparation method of this anti-discoloration nano-silver sol comprises the following steps:

[0044] Add 50g of amino acid and 47.5g of silver nitrate solid into 1L of deionized water to dissolve, prepare the oxidation solution and pour it into the reaction kettle, heat the oxidation solution to 120°C, and stir the oxidation solution at a speed of 100rpm;

[0045] Add 2L of glycerol to 18L of water and dissolve to prepare a reducing solution;

[0046] Add the reducing solution dropwise to the reactor at a rate of 30 drops / min with a single injection flow controller;

[0047] Continue to stir for 2 h after the addition of the reducing solution is completed, to obtain a light yellow transparent nano-silver colloid with an average particle size of 20 nm. According to the Volhard method, the silver content of the nano-silver colloid is 1372mg / kg. At the same time, the light yellow liquid is dried in an oven at 80°C and determined to be simple silver by XR...

Embodiment 3

[0051] Embodiment 3 The preparation method of this discoloration-resistant nano-silver sol comprises the following steps:

[0052]Dissolve 15g of polyvinylpyrrolidone, 10g of sodium benzenesulfonate and 60g of silver nitrate in 1L of deionized water to prepare an oxidation solution. Pour the oxidation solution into the reaction kettle and heat the solution to 115°C. speed to stir it;

[0053] Dissolve 4.6Kg of glycerol into 1.8L of deionized water to prepare a reducing solution;

[0054] Add the reduction solution dropwise to the oxidation solution at a rate of 300 drops / min controlled by a single flow rate agent, and continue stirring for 0.5 h after the dropwise addition to obtain grayish-yellow viscous nano-silver colloid with a particle size of 60 nm.

[0055] Measured according to the Volhard method, the silver content concentration of the nano-silver colloid is 5151mg / kg;

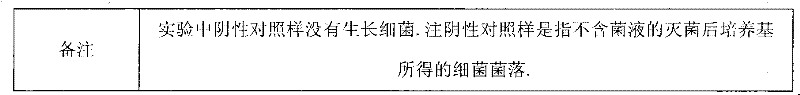

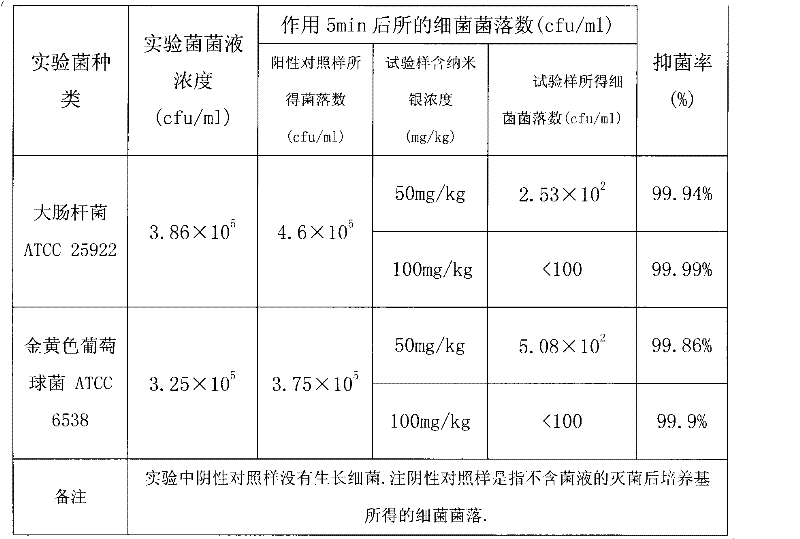

[0056] Afterwards, the nano-silver colloid was diluted 100 times and its antibacterial effect wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com