Nerve conduit stent and preparation method thereof

A nerve conduit and polyhydroxyalkanoate technology, applied in the fields of biomedical materials and tissue engineering, can solve problems such as difficult large-scale production, poor mechanical strength and machining performance, and difficult quality control, and achieve good biocompatibility , broad application prospects, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

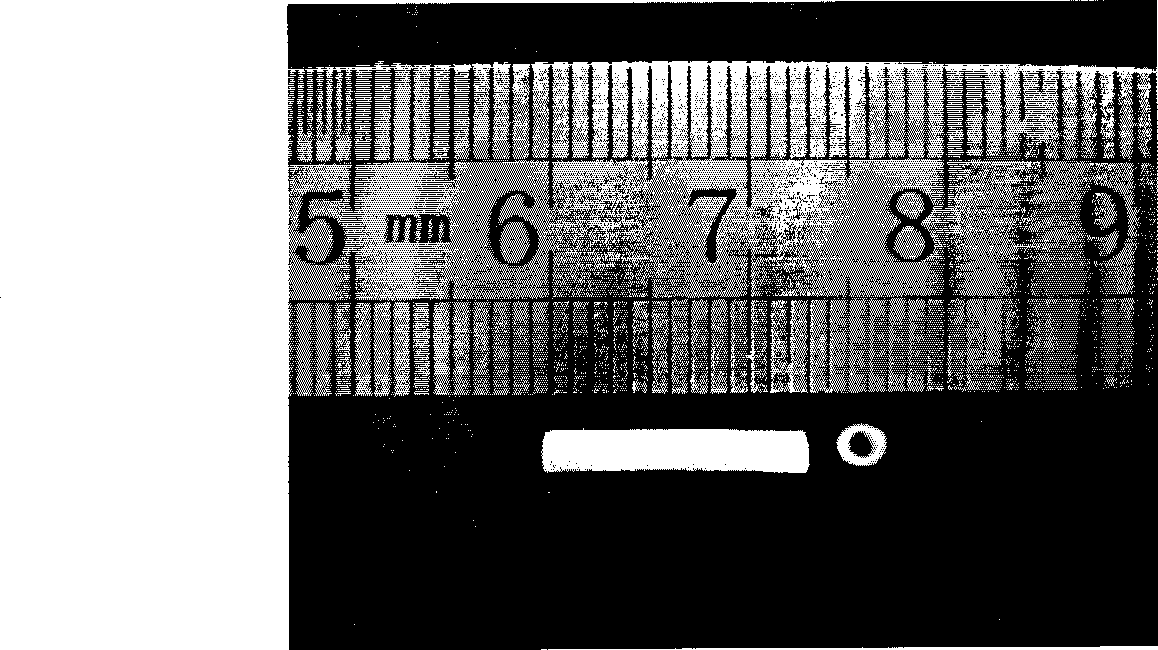

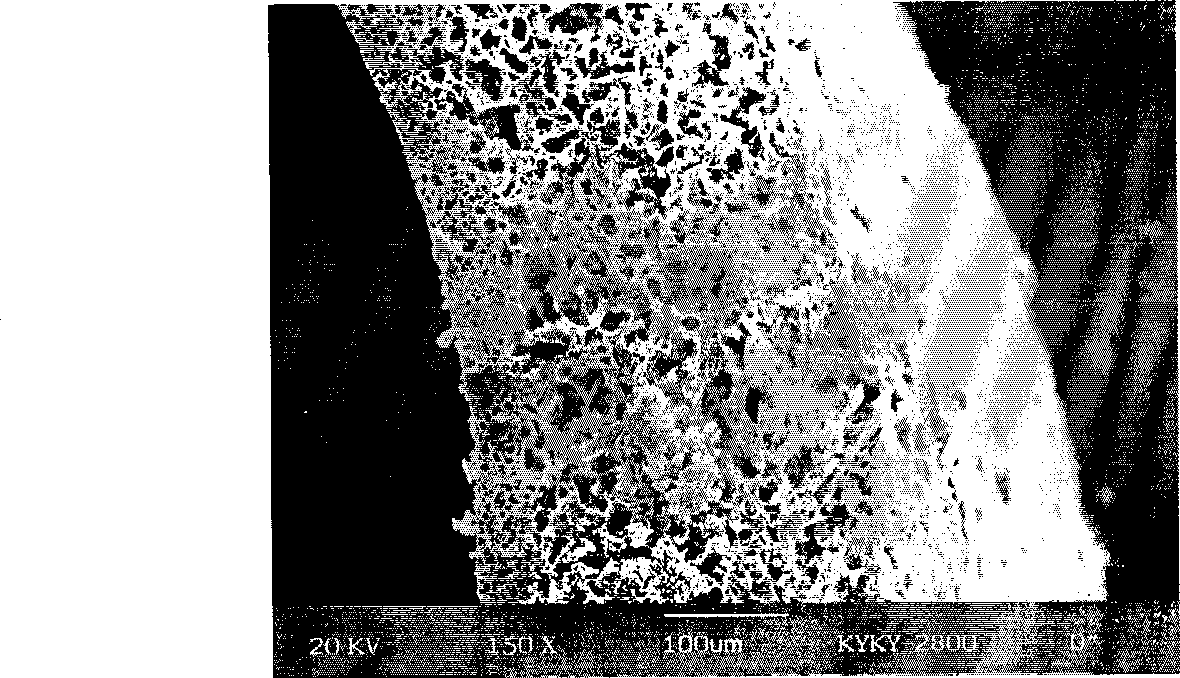

[0032] Preparation of PHBHHx nerve conduit scaffolds with a diameter of 1.5 mm, a length of 12 mm, and a wall thickness of 0.25 mm

[0033] Using polyhydroxybutyrate-hexanoate (PHBHHx, purchased from Shandong Lukang) as raw material, the PHBHHx nerve conduit stent with a diameter of 1.5 mm, a length of 12 mm, and a tube wall thickness of 0.25 mm comprises the following steps:

[0034] 1) In a flask, polyhydroxybutyrate-caproic acid ester and 1,4-dioxane are mixed at a mixing ratio of 10 mL 1,4-dioxane per gram of polyhydroxybutyric acid-caproic acid ester. Stir and heat in a water bath at 60°C, and condense and reflux for about 2 hours to obtain a homogeneous solution;

[0035] 2) Pour the solution obtained in step 1) into two test tubes, add salt particles with a diameter of less than 10 microns and salt particles with a diameter of 50 ± 20 microns, and stir evenly with a glass rod to obtain a uniform mixture. The volume mass ratio of hydroxybutyric acid-caproic acid ester s...

Embodiment 2

[0039] Preparation of PHB nerve conduit scaffolds with a diameter of 2 mm, a length of 30 mm, and a wall thickness of 0.25 mm

[0040] Using poly 3-hydroxybutyrate (PHB, purchased from Shandong Lukang) as a raw material, prepare a PHB nerve conduit stent with a diameter of 2 mm, a length of 50 mm, and a tube wall thickness of 2.5 mm, including the following steps:

[0041] 1) Mix poly 3-hydroxybutyrate and 1,4-dioxane in a flask at a mixing ratio of 20mL 1,4-dioxane per gram of poly 3-hydroxybutyrate, at 70°C Stir and heat in a water bath, and condense and reflux for about 0.5 hours to obtain a homogeneous solution;

[0042]2) Pour the solution obtained in step 1) into two test tubes, add salt particles with a diameter of less than 10 microns and salt particles with a diameter of 60 ± 20 microns, and stir evenly with a glass rod to obtain a uniform mixture. The volume mass ratio of hydroxybutyric acid-caproic acid ester solution and the salt particle below 10 microns in diame...

Embodiment 3

[0045] Preparation of PHBV nerve conduit scaffolds with a diameter of 4 mm, a length of 50 mm, and a wall thickness of 0.25 mm

[0046] Using 3-hydroxybutyrate valeric acid copolyester (PHBV, purchased from Shandong Lukang) as raw material, prepare a PHBV nerve conduit stent with a diameter of 4 mm, a length of 50 mm, and a tube wall thickness of 0.25 mm, including the following steps:

[0047] 1) Mix 3-hydroxybutyrate valeric acid copolyester and 1,4-dioxane in a flask at a mixing ratio of 8 mL 1,4-dioxane per gram of 3-hydroxybutyrate valeric acid copolyester ring, stirred and heated in a water bath at 65°C, and condensed and refluxed for about 4 hours to obtain a homogeneous solution;

[0048] 2) Pour the solution obtained in step 1) into two test tubes, add salt particles with a diameter of less than 10 microns and salt particles with a diameter of 50 ± 20 microns (water-soluble particles are acceptable), and stir evenly with a glass rod. Obtain a homogeneous mixture, whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com