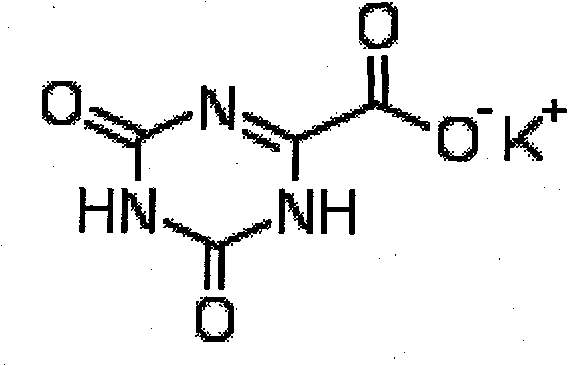

Refining method for preparing high-purity oteracil potassium

A technology of potassium oxonate and a purification method, applied in directions such as organic chemistry, can solve the problems of not specifying product purity, not providing a purification method, etc., and achieving the effects of not easy side reactions and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

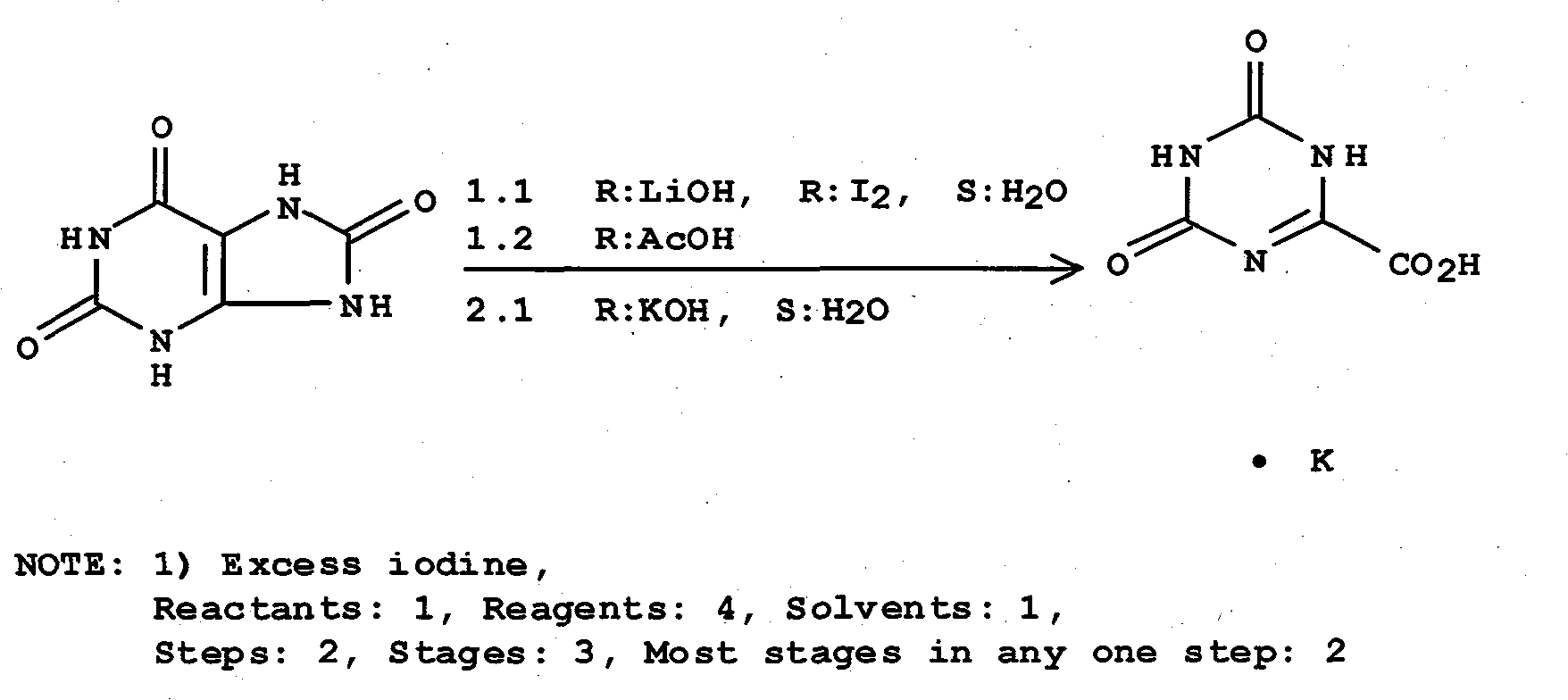

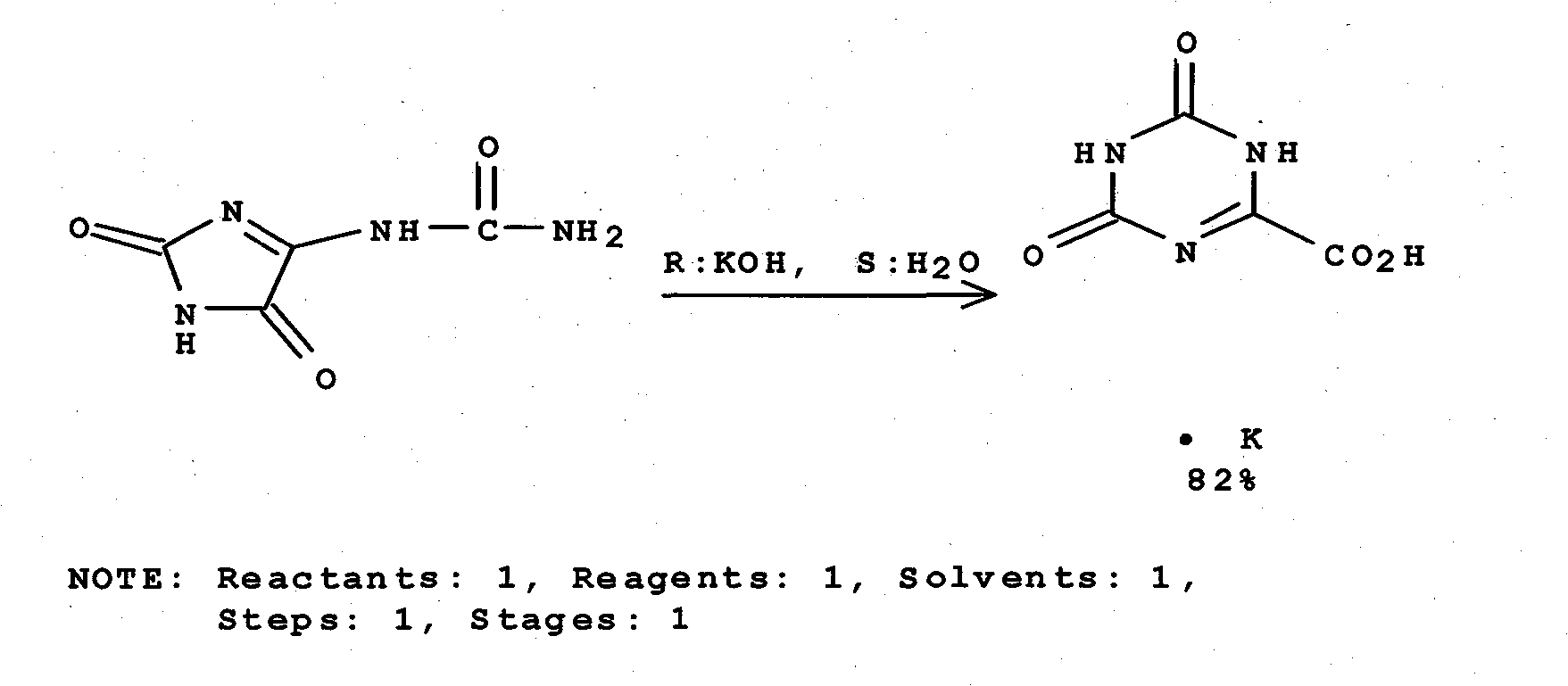

Method used

Image

Examples

Embodiment 1

[0029] Add 10g of crude potassium oxonate to 90ml of water, add 10% potassium hydroxide solution under stirring until the crude product is completely dissolved, then add 8.5ml of acetone, stir at 25°C for half an hour, and adjust the pH to 6.9-7.2 with 10% hydrochloric acid while stirring , white crystals were precipitated, after the crystallization was completed, the filter cake was washed with acetone, and the filter cake was vacuum-dried, and weighed to obtain 9.2 g of high-purity potassium oxonate, with a yield of 92% and a purity of 99.98% (HPLC detection).

Embodiment 2

[0031] Add 10g of crude potassium oxonate potassium into 70ml of water, add 15% potassium carbonate solution under stirring until the crude product is completely dissolved, then add 7ml of methanol, stir at 10°C for half an hour, adjust the pH to 6.9-7.2 with 8% sulfuric acid while stirring, and White crystals were precipitated, and after the crystallization was completed, the filter cake was filtered, washed with methanol, dried in vacuum, and weighed to obtain 9.5 g of high-purity potassium oxonate, with a yield of 95% and a purity of 99.96% (HPLC detection).

Embodiment 3

[0033] Add 10g of crude potassium oxonate potassium to 100ml of water, add 10% potassium hydroxide solution under stirring until the crude product is completely dissolved, then add 10ml of ethanol, stir at 35°C for half an hour, adjust the pH to 6.9-7.2 with 15% formic acid while stirring, White crystals were precipitated, and after the crystallization was completed, the filter cake was filtered, washed with ethanol, dried in vacuum, and weighed to obtain 9.3 g of high-purity potassium oxonate, with a yield of 93% and a purity of 99.95% (HPLC detection).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com