Preparation of spiral polymer emulsion

A polymer emulsion and polymer technology, applied in the field of polymer materials, can solve the problems of poor solubility and processability of spiral polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

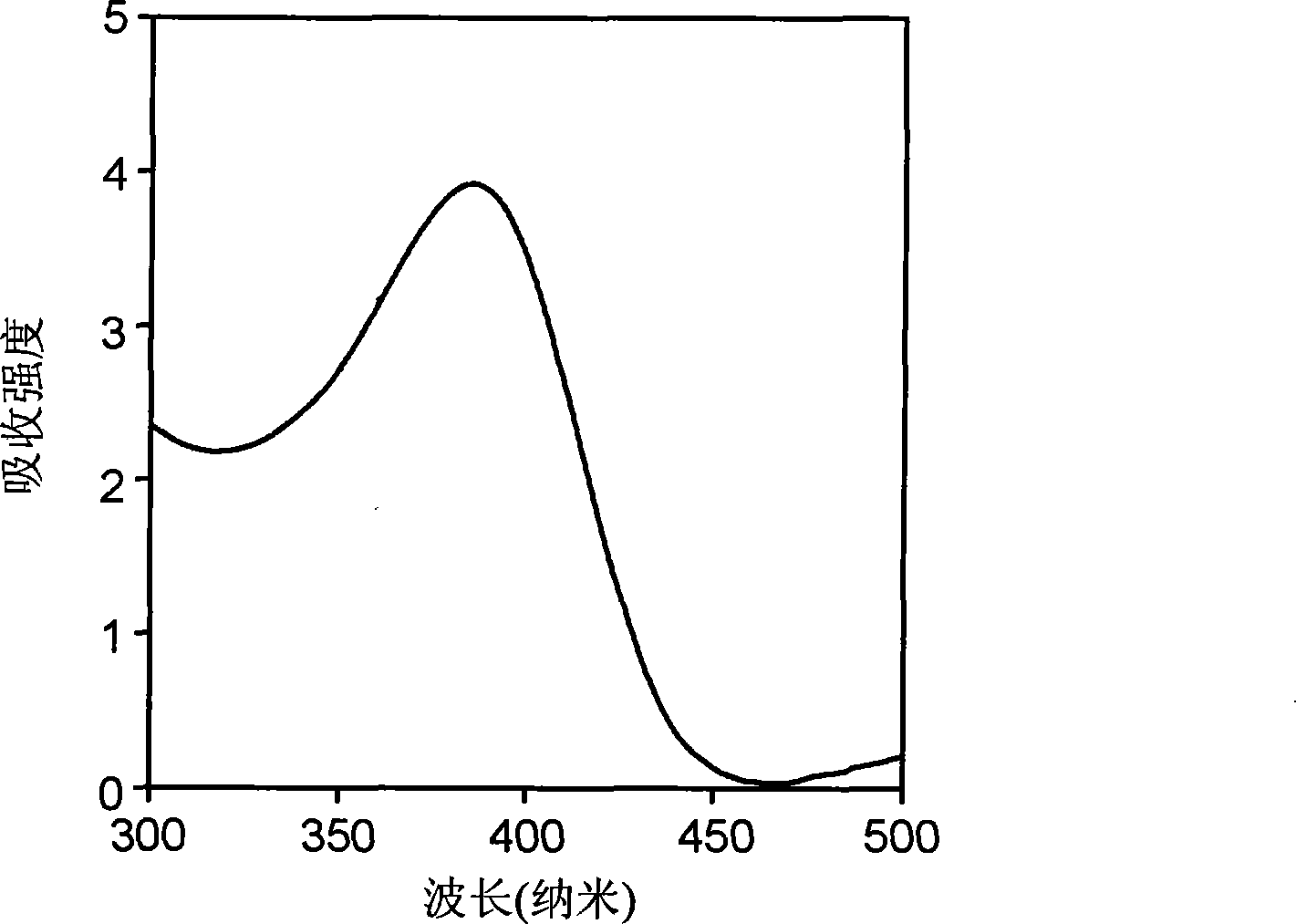

[0039] Dissolve 0.735g of surfactant SDS in 15ml of deionized water to form a surfactant solution, control the temperature at 0°C, stir until dissolved at a stirring speed of 300r / min, and then dissolve the monomer 0.13g was dissolved in 2ml of DMF, the molar ratio of monomer to surfactant was 1:3, the DMF containing monomer was added dropwise in the surfactant solution, stirred for 20 minutes under nitrogen protection to form a mixed solution, and 0.0087 The g metal Rh catalyst was dissolved in 1ml of DMF, and the DMF containing the catalyst was added dropwise to the above mixed solution, and stirred for 0.5 hours under nitrogen protection to obtain an orange-yellow spiral polymer emulsion.

Embodiment 2

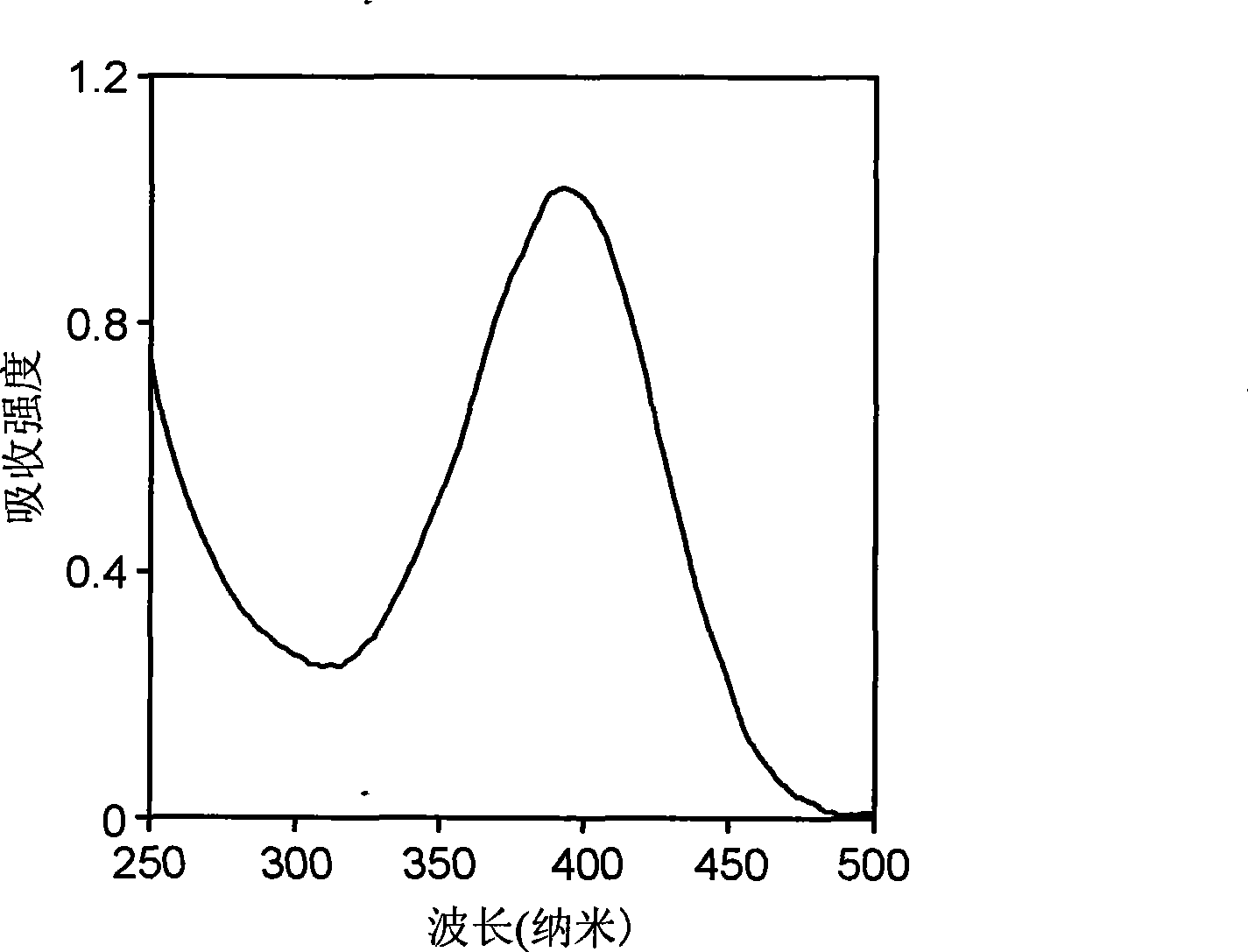

[0041] Dissolve 1.65 g of the surfactant Triton X-100 in 15 ml of deionized water to form a surfactant solution, the co-emulsifier is THF, and the operation process is the same as in Example 1.

Embodiment 3

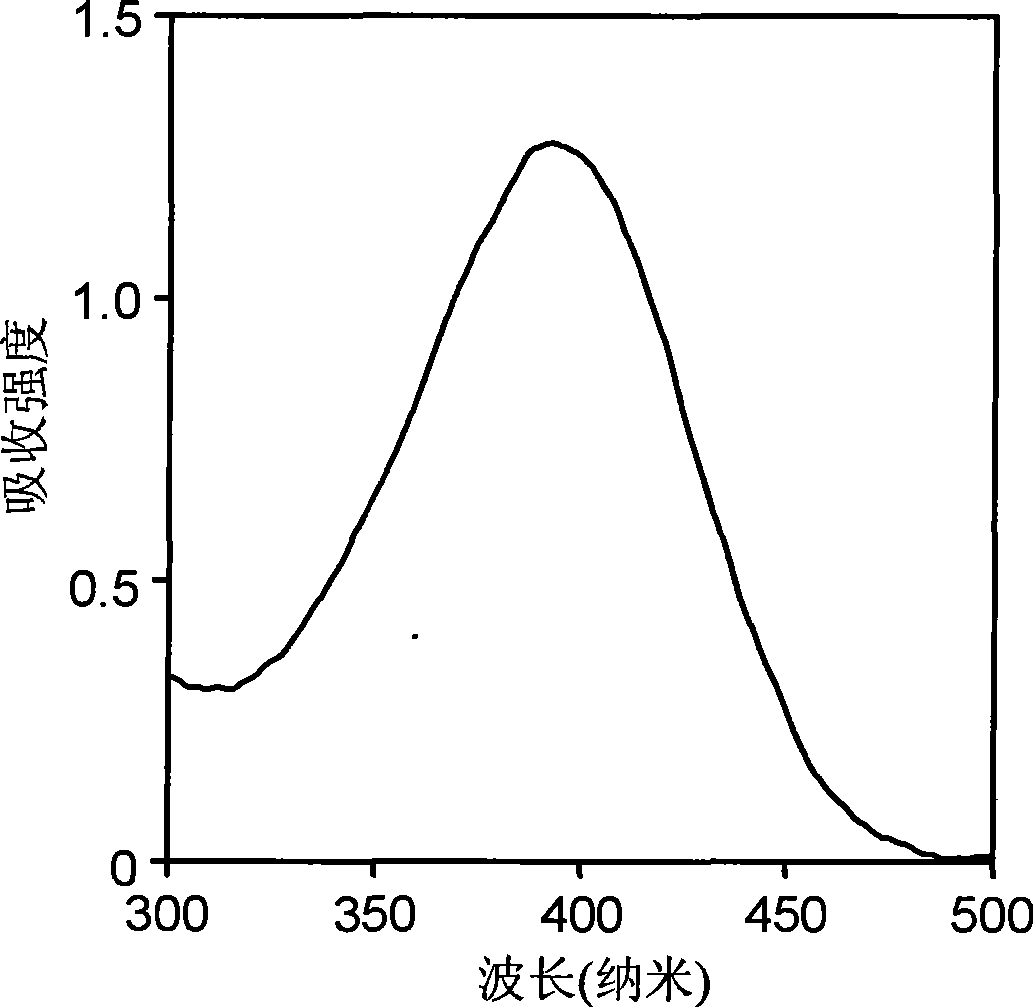

[0043] Dissolve 2.94g of surfactant SDS in 15ml of deionized water to form a surfactant solution, control the temperature at 30°C, stir until dissolved at a stirring speed of 500r / min, and then dissolve the monomer 0.26g was dissolved in 2ml of DMF, the molar ratio of monomer to surfactant was 1:6, the DMF containing monomer was added dropwise in the surfactant solution, stirred for 20 minutes under nitrogen protection to form a mixed solution, and 0.0087 The g metal Rh catalyst was dissolved in 1ml of DMF, and the DMF containing the catalyst was added dropwise to the above mixed solution, and stirred for 2 hours under nitrogen protection to obtain an orange-yellow spiral polymer emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com