Oil and gas well fracturing fluid for 180-200 DEG C high temperature strata

A fracturing fluid and oil and gas well technology, applied in the field of oil and gas well fracturing fluid, can solve the problems of delaying crosslinking performance, reducing flow friction, increasing high shear time, etc., achieving good gel breaking effect and good shear resistance , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

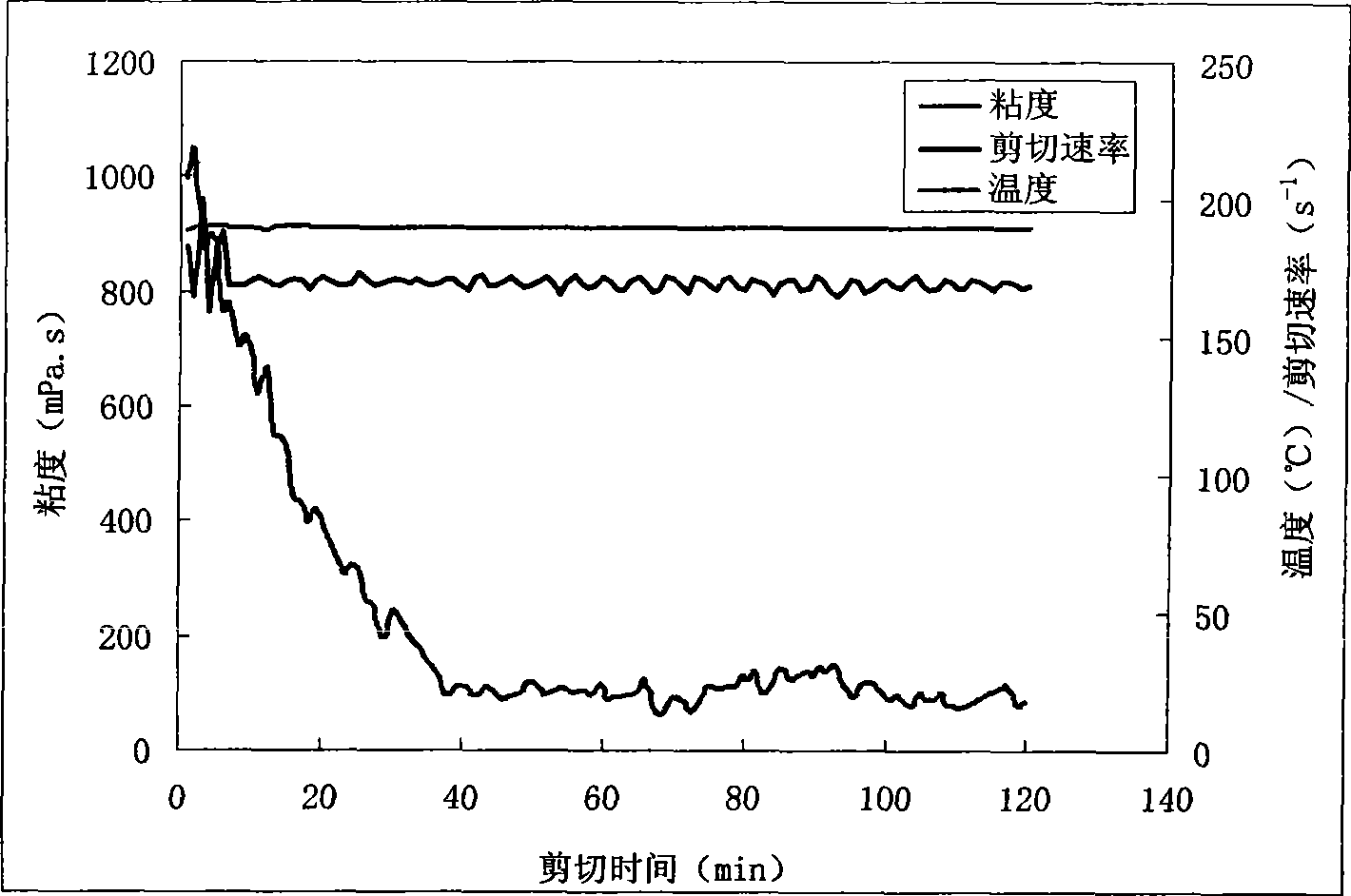

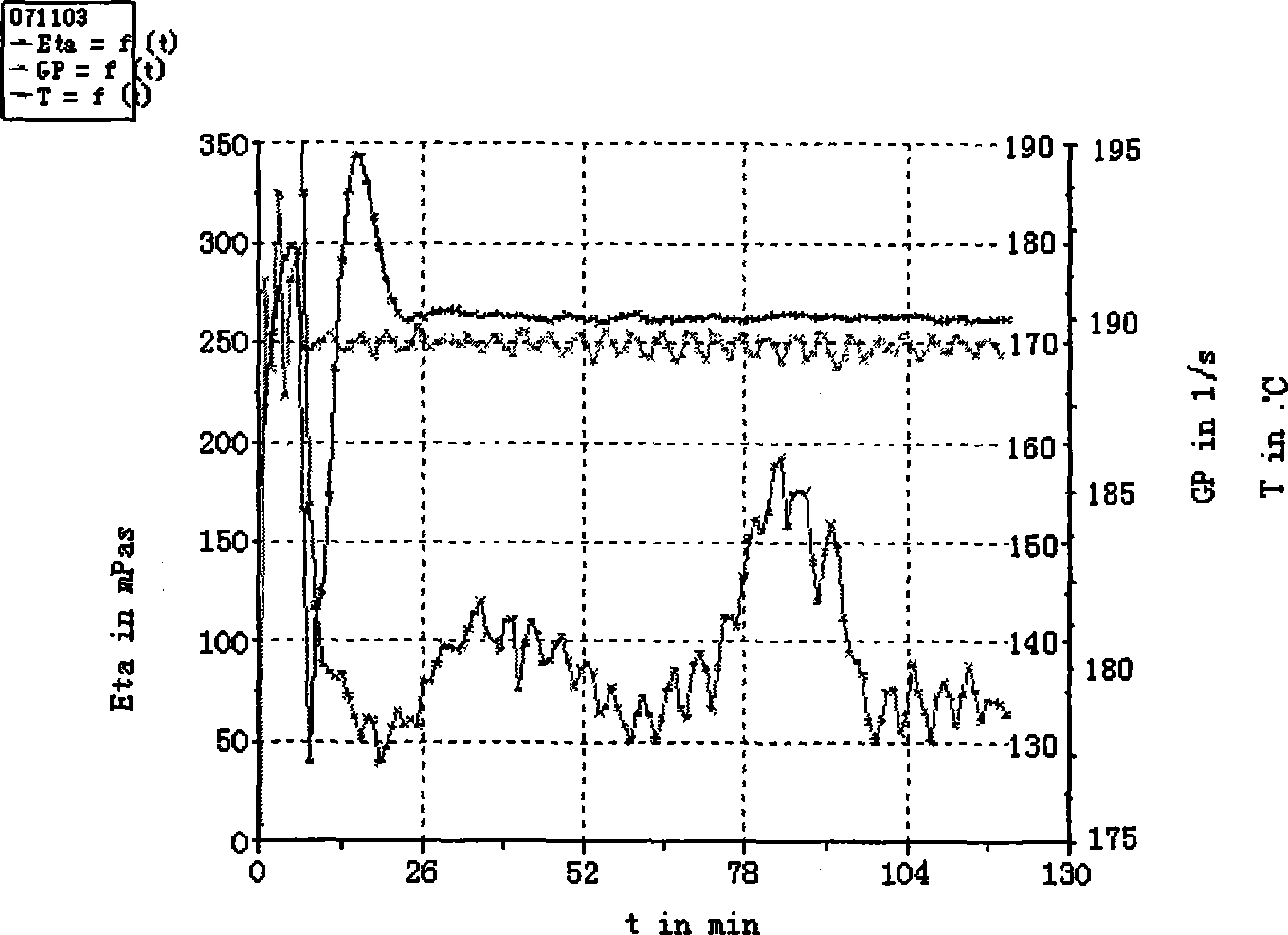

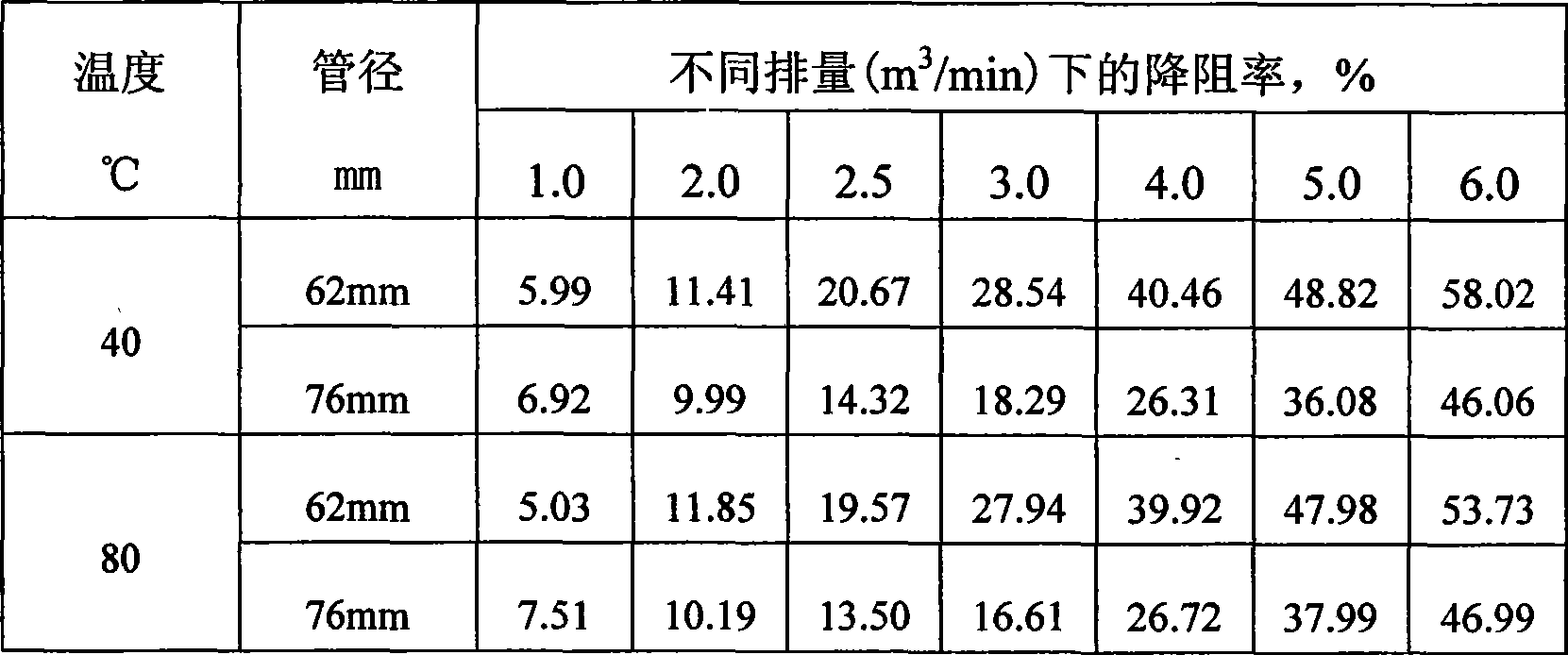

Embodiment 1

[0012] Weigh 5.4g of hydroxypropyl carboxymethyl guar gum and 20g of potassium chloride and mix evenly under the solid phase, add 1000ml of water, stir in the mixer for 10min, leave the liquid for half an hour to fully swell the guar gum, then add 5g Formaldehyde, 5g 1,3-di(alkylamine oxide)-2-propanol, add 1.5g sodium bicarbonate, 5g copolymer of vinylpyrrolidone and ethylene-1-substituted methyl trialkyl ethylamine chloride ether and 5g N, N-dialkylhydroxylamine, the preparation of the base liquid was completed, and the apparent viscosity of the base liquid was measured to be 77mpa·s, and the surface tension was 32.2mN / m.

Embodiment 2

[0014] Weigh 5.5g of hydroxypropyl carboxymethyl guar gum and 20g of potassium chloride and mix evenly under the solid phase, add 1000ml of water, stir in the mixer for 10min, leave the liquid for half an hour to fully swell the guar gum, then add 5g Formaldehyde, 5g 1,3-di(alkylamine oxide)-2-propanol, add 1.5g sodium bicarbonate, 5g copolymer of vinylpyrrolidone and ethylene-1-substituted methyl trialkyl ethylamine chloride ether and 5g N, N-dialkylhydroxylamine, the preparation of the base liquid was completed, and the apparent viscosity of the base liquid was measured to be 82mpa·s.

Embodiment 3

[0016] Weigh 5.6g of hydroxypropyl carboxymethyl guar gum and 20g of potassium chloride and mix evenly under the solid phase, add 1000ml of water, stir in the mixer for 10min, leave the liquid for half an hour to fully swell the guar gum, then add 5g Formaldehyde, 5g 1,3-di(alkylamine oxide)-2-propanol, add 1.5g sodium bicarbonate, 5g copolymer of vinylpyrrolidone and ethylene-1-substituted methyl trialkyl ethylamine chloride ether and 5g N, N-dialkylhydroxylamine, the preparation of the base liquid was completed, and the apparent viscosity of the base liquid was measured to be 84mpa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com