Multi-directional air distribution fixed bed biomass gasification stoves

A biomass and fixed bed technology, applied in coke ovens, special dry distillation, petroleum industry, etc., can solve the problems of unfavorable environmental protection, low strength, high tar content, etc., and achieve environmental protection, enhanced reaction intensity, Effect of reducing tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

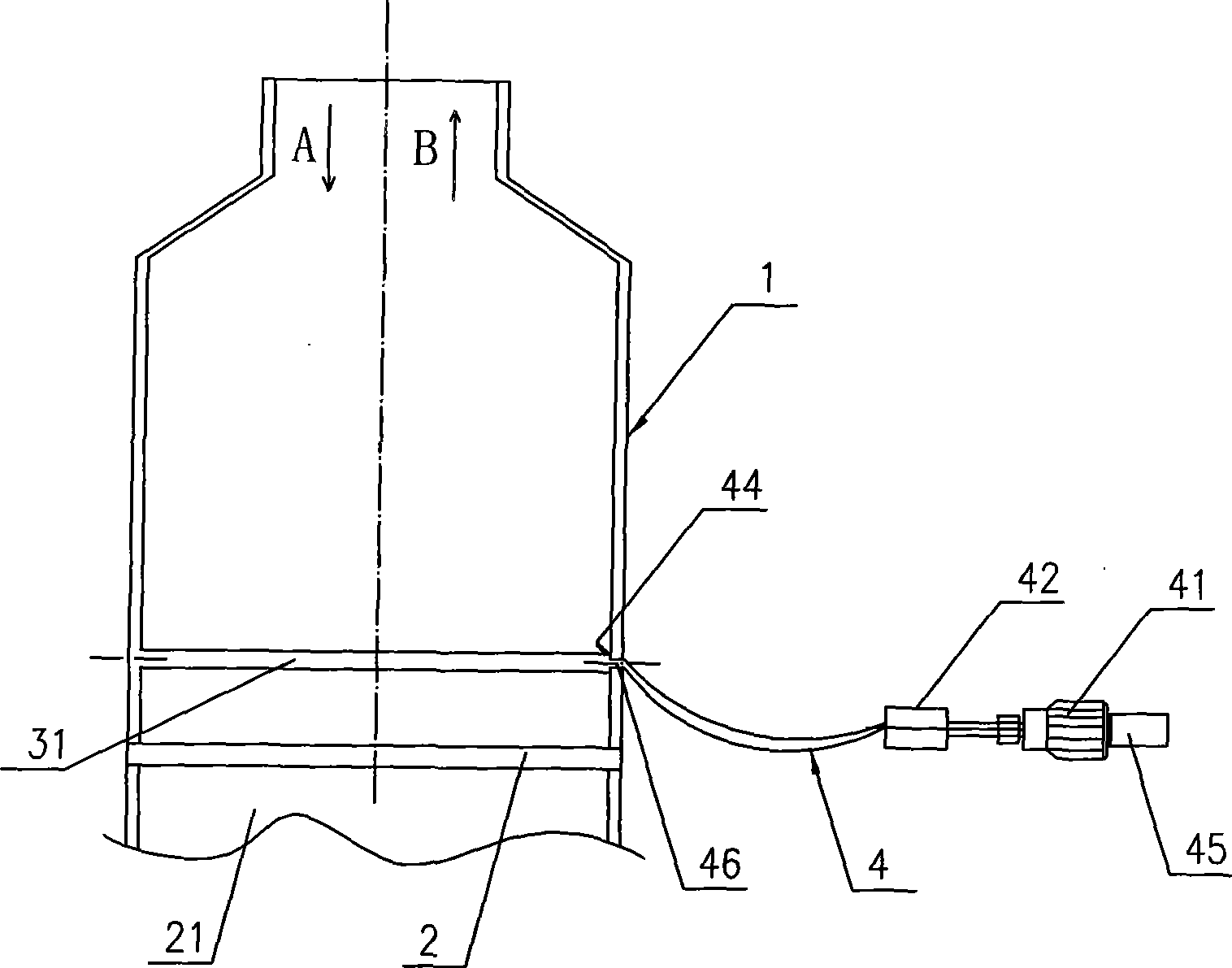

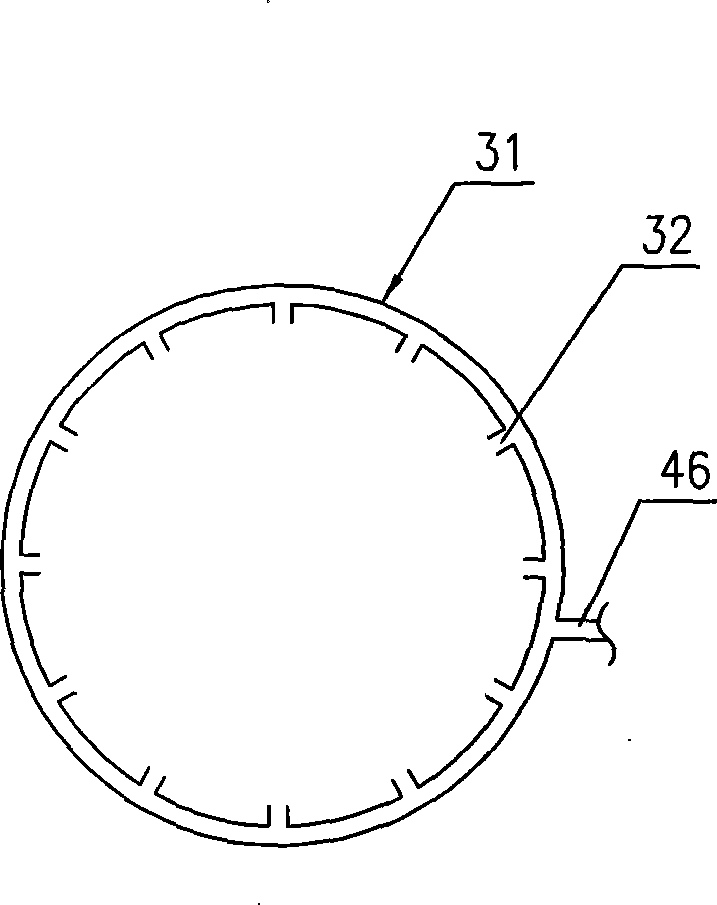

[0049] Such as figure 1 and figure 2 Shown is an embodiment 1 of a multi-air distribution fixed-bed biomass gasifier of the present invention, including a furnace body 1 and a fire grate 2, the fire grate 2 is arranged in the middle of the furnace body 1, and the bottom of the furnace body 1 is ash The slag chamber 21, the furnace diameter of the furnace body 1 is 1.2m, which belongs to the small inner diameter fixed bed gasifier, the biomass raw material used in this embodiment is wood block, and the wood block is fed from the top A of the furnace body 1, and the furnace body 1 There is a forced air intake system on the top, the forced air intake system includes the air supply mechanism 4, the air distribution device and the connecting pipe. There are several air distribution holes 32 for supplying air into the furnace body 1, forming an annular air distribution pipe 31. In this embodiment, the air distribution holes 32 are opened toward the central axis of the circular pip...

Embodiment 2

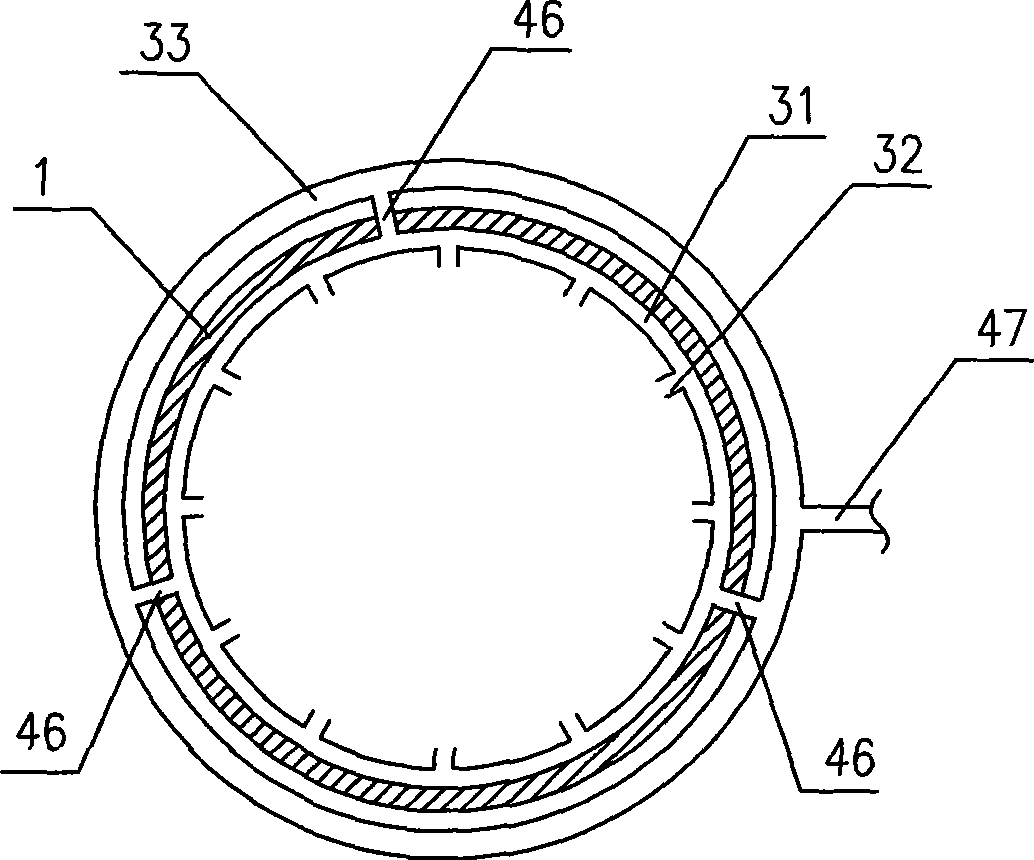

[0055] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is: the connection mode between the annular air distribution pipe 31 and the fan 42 is different, and the present embodiment adopts the following scheme: the air supply pipe of the air supply mechanism 4 is located at the periphery of the furnace body 1 The total air supply pipe 33 of the annular structure, the total air supply pipe 33 is connected with the annular air distribution pipe 31 in the furnace through the connecting pipe 46, the air first enters the main air supply pipe 33, and then enters the annular air distribution pipe through the connecting pipe 46 31, and flow into the furnace body 1 through the air distribution hole 32.

Embodiment 3

[0057] Such as Figure 4 and Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the biomass raw material used in this embodiment is straw, which is easy to bridge in the furnace body, and when burning, the straw in the lower part will burn out and cause a flameout phenomenon. The rice straw in the example is fed from the side A of the furnace body, and the diameter of the furnace body is greater than 1.2m, which belongs to the large inner diameter fixed bed gasification furnace. In addition to the circular pipe-type air distribution structure of the embodiment 1, the following two types of distribution are also used in this embodiment: Wind device:

[0058] Straight pipe air distribution structure, the straight pipe air distribution structure in this embodiment is that several air distribution holes 53 are arranged on two straight pipes to form an air distribution straight pipe 52, and the air distribution holes 53 are all upward on the straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com